iGOLDENCNC Furniture Making Machine

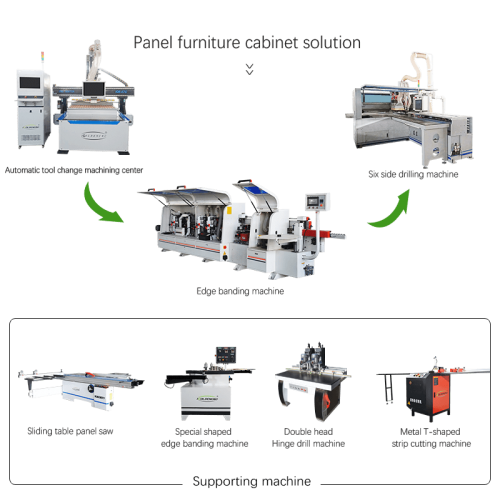

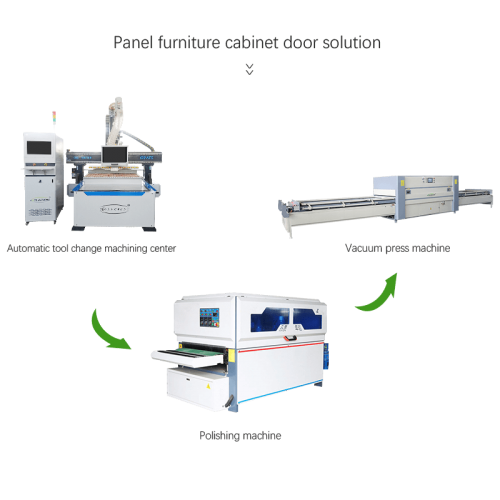

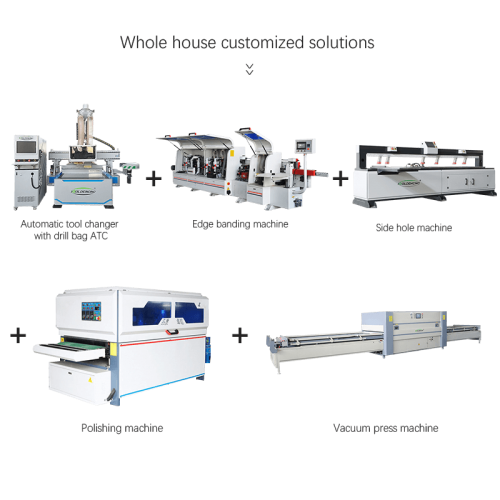

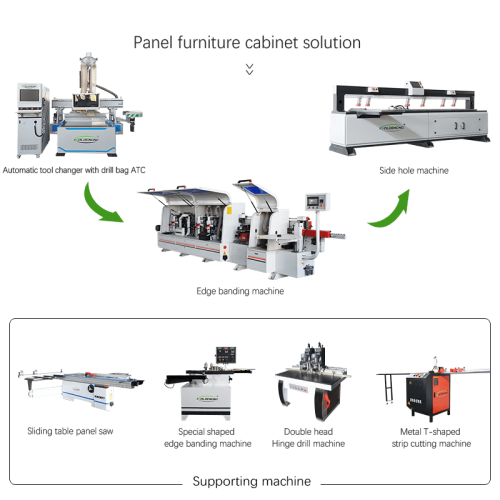

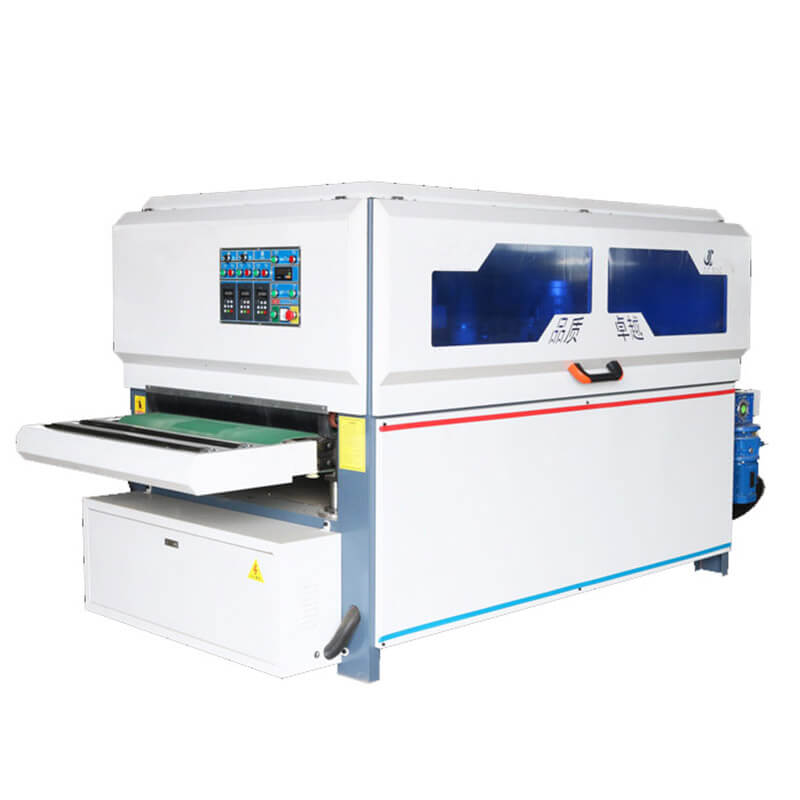

Our furniture CNC machine covers nesting CNC, edge banding machine, vacuum press machine, polishing machine, side drilling machine, six-sided drilling machine, sliding table saw, computer beam saw, hinge drill, etc. All these furniture making machines can process hardwood, softwood, MDF, particleboard, plywood and other wood materials to produce tables, chairs, kitchen cabinets, wardrobes, cupboards, shelves, beds, and other modern CNC furniture.

iGOLDEN furniture CNC production line offers a wide range of furniture CNC machine used in the panel furniture production line for furniture makers, cabinet makers, custom furniture manufacturers, and other woodworkers from China, USA, Canada, Russia, South Africa, Australia, India, Bangladesh, UK, UAE, and other countries and regions.