Auto Double Repair Edge Banding Machine

The edge banding machine is a kind of woodworking machinery and an important processing flow of furniture production line. It is used to repair excess edge banding material above and below the edge band of the plate.

This is a fully automatic edge banding machine with the characteristics of high automation, high efficiency, high precision and beautiful appearance. It can complete the functions of gluing, edge banding, end cutting, rough trimming, fine trimming, scraping, polishing, etc.Equipped with a fully enclosed safety shield, it can ensure operator safety and protect the environment.

Edge Banding Machine Video

Edge Banding Machine Parameter

Technical Data

| Specific functions | pre-milling, gluing 1, pressing belt 1, gluing 2, pressing belt 2, end cutting, rough trimming, finishing, profiling tracking, edge scraping, polishing 1, polishing 2 |

| Sheet thickness | 9-60mm |

| Minimum processing width of sheet | ≥80mm |

| Minimum processing length of sheet | ≥120mm |

| Edge banding width | 15-55mm |

| Conveyor belt power | 3.7kw |

| Feeding speed | 15~22m/min |

| Total power | 20kw |

| Dimensions | 7900*900*1600mm |

| Weight | 2600kg |

We offer customized services according to your requests such as the working area and specifications.

Applications Of Edge Banding Machine

Edge banding machines are mainly used for banding the edges of various panel furniture. For instance, cabinets, wardrobes, shelves, custom furniture, office furniture, tables, chairs, windows, doors, cupboards, and other wood products.This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

Edge Banding Machines Wood Features:

Pre-milling: Double milling cutters are used to modify the ripple marks, burrs or non-vertical phenomenon caused by the panel saw processing to achieve better edge sealing effect and to make the edge band and the board more tightly fit, better integrity and aesthetics.

Adhesive edge banding: Adopting a special structure, evenly apply adhesive on both sides of the edge banding plate and edge banding material to ensure a stronger adhesion.

Head-to-head: through precise linear guide rail movement, adopts automatic tracking of the mold and high-frequency high-speed motor fast cutting structure to ensure the cut surface is smooth and smooth.

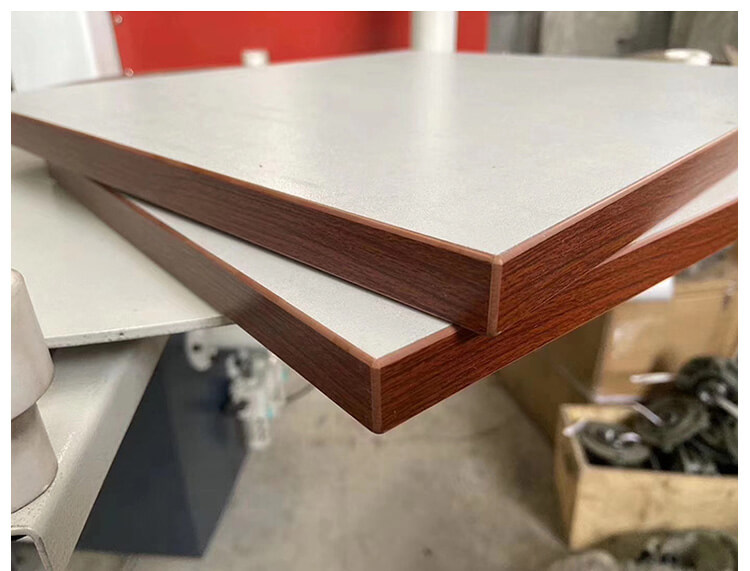

Finishing: Both the profile automatic tracking and high-frequency high-speed motor structure are used to ensure the smoothness of the upper and lower parts of the trimmed board. It is used to repair excess edge banding material above and below the edge band of the plate. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding for panel furniture. Edge banding with thickness of 0.8 mm or more is preferred.

Scraping: Used to eliminate the ripple marks caused by the non-linear motion of the trimming process, so that the upper and lower parts of the board are smoother and cleaner.

Polishing: Clean the processed sheet with a cotton polishing wheel, and make the edge sealing end surface smoother by polishing.

Slotting: It is used for direct slotting of wardrobe side panels, bottom plates, etc., reducing the process of panel sawing, and it is more convenient and fast. It can also be used for slotting of aluminum edging of door panels.

Contact Us Today to Get Price!

The edge banding machine is a kind of woodworking machine dedicated for cabinet edge banding. It plays the role of edgebanding in the processing process of the furniture production line. Compared with the traditional manual banding process, the sealing line of the edge bander has the advantages of being straight, delicate, and smooth.

As we all know, cabinet edge banding plays an important role in furniture production. Good edge banding makes the cabinets more beautiful and smoother. Besides, it can effectively control the release of formaldehyde in the panel, making our home more environmentally friendly. Therefore, the edge bander is an indispensable furniture making machine for the whole panel furniture production line.

A banding machine for cabinet edges mainly includes the main structure, multiple processing units, and the control system. The processing units include the pre-milling unit, banding tape conveying unit, banding unit, cutting unit, trimming unit, rounding unit, scraping unit, and polishing unit. Each of these units corresponds to one separate function.

Relying on the advantages of high automation, stable operation, reliability, durability, and moderate price, edge banding machines are especially suitable for large and medium-sized furniture, cabinets, and other panel furniture manufacturers.

Portable Handheld Edge Bander

The portable handheld edge bander can be applied to the operation of plate straight and curved irregular borders. When the machine is installed with the fixed bracket accessories, its use method is similar to that of the traditional curved line manual edge bander. It is suitable for banding of various materials, including melamine (impregnated) paper, veneer, plastic (PVC or ABS).

Semi-Automatic Edge Bander

The semi-automatic edge banding machine is suitable for straight edge banding of MDF, blockboard and particleboard. Its capabilities include gluing, sealing, upper and lower trimming, and polishing. It is an automatic production line that can complete the conveying of panel, edge banding, upper & lower milling, and polishing at one time.

Automatic Edge Bander

The automatic edge banding machine is suitable for straight banding & trimming of solid wood, fiberboard, particleboard, MDF, plywood. The materials can be solid wood strips, PVC, melamine, and veneer. Its capabilities include pre-milling, gluing, banding, leveling, roughing, finishing, profiling, scraping, polishing, grooving.

Precision Edge Application: The Wood Edge Banding Machine excels in precisely applying edge bands to the edges of various wooden panels. This process not only enhances the aesthetics of the panels but also provides protection and durability to the edges.

Versatile Material Compatibility: It is compatible with a wide range of edge banding materials, making it suitable for different applications. Whether you’re working with solid wood, plywood, MDF, or other wooden materials, this machine can handle it.

Multiple Functions: This machine typically performs a series of operations, including rough trimming, fine trimming, edge band application, corner rounding, scraping, and polishing. These functions ensure a seamless and high-quality finish.

High Efficiency: The Wood Edge Banding Machine is known for its efficiency. It can process panels of various sizes and thicknesses with precision, making it a valuable asset for mass production in furniture and cabinetry manufacturing.