4 Axis 5 Axis Cutting Bridge Saw

This stone CNC machining center can cut quartz, marble, granite, and rock slabs with a powerful saw blade. It combines a saw blade and CNC router tools to achieve multiple advanced functions. For example, cutting and milling straight and inclined edges, chamfering, cutting arc edges, polygon, edge milling, edge tracking, and other powerful functions. The 5 axis bridge saw is widely used in the stone processing plants, kitchen countertop processing, background wall profiling, and other fields.

Request a QuoteStone CNC Router Cutting Machine Samples

5 Axis CNC Stone Cutting Machine Buyer Guide

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations.

Heavy Machine Body

A rectangular tube welding bed with a thickness of 6mm, a seamless welding process for steel structure, through large-scale gantry milling, all the basic installation holes are accurately drilled at one time and annealed.

Third-generation Gantry

The thickened rectangular tube beam can bear a weight of less than 1000 kg and is annealed.

High strength, good rigidity, lightweight, no deformation, long service life.

The damage to the motion transmission device is small, and the resistance to the drive motor is small so that the gantry accuracy is maintained for a long time, the service life is improved, and the maintenance and use costs are reduced.

Large Reversible Template Workbench

The tabletop is lifted by pneumatic balls for easy feeding.

A variety of configurations are available to realize a variety of processes.

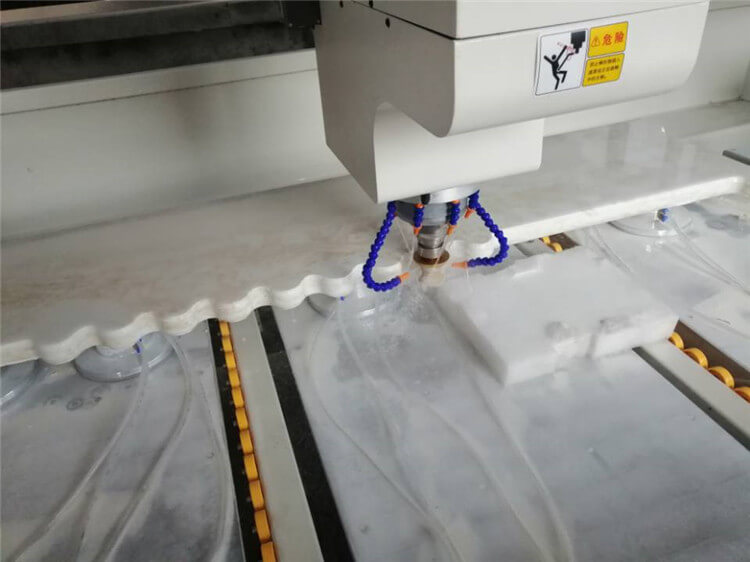

Large Saw Blade

4kw high-power large saw blade cutting depth 10cm.

Pure copper motor, 360° automatic rotating head.

Low noise, long life, all-round cutting.

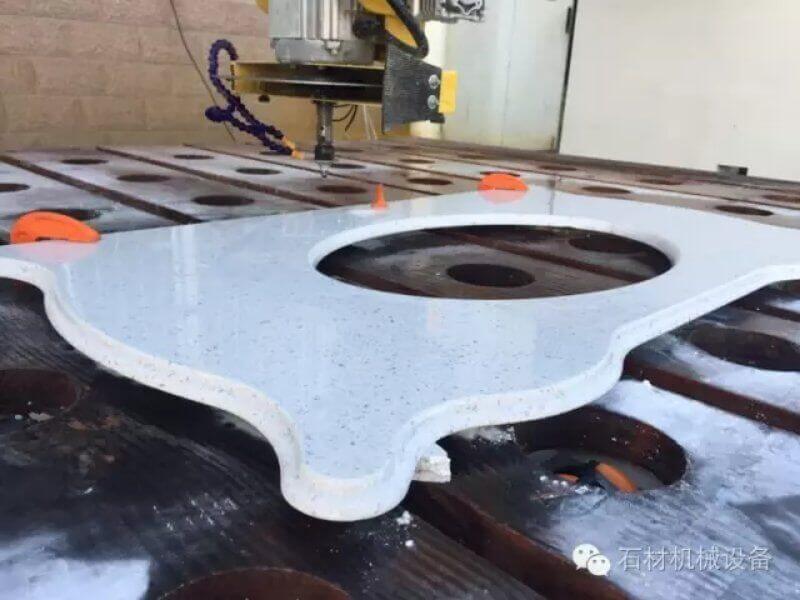

The 5 axis CNC stone bridge saw is good at cutting, milling, chamfering and edging quartz, marble, artificial stone and slabs in regular and irregular shapes. It can realize countertop cutting, bridge cutting, roman column cutting, arc line cutting, concave-convex cutting, and irregular edge cutting and milling.

The automatic stone cutting bridge saw can process products of sanitary ware, stone furniture, interior decoration, and other fields. For example, wash basins, bathroom countertop, stone tables, dinning tables, kitchen tables, kitchen cabinet basins, background wall, roman edge stone decorations, etc.

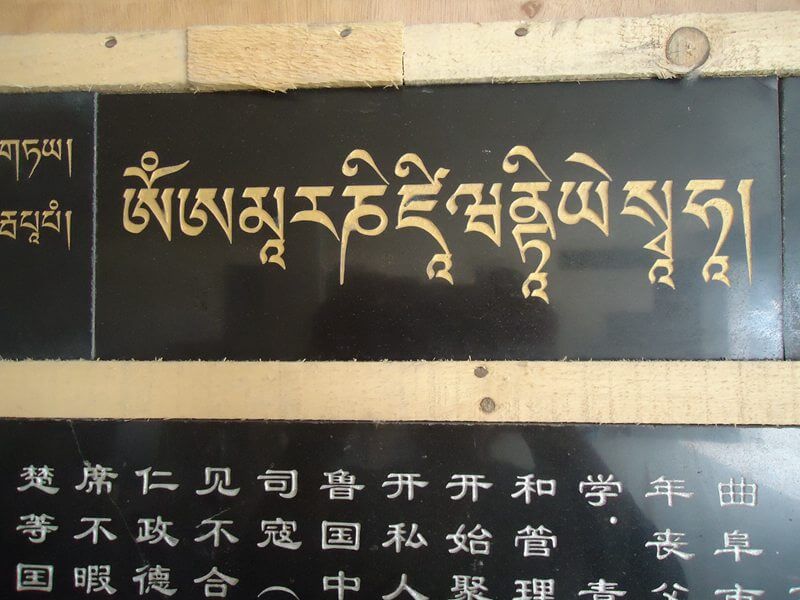

CNC stone engraving machine, installed with the special design software in the computer, for finishing the graphics and character design, layout, automatically generate processing path information, then through the USB interface or other data transmission interface to transmit tool path data to single-chip microcomputer, CNC system receives tool path data, completes display and user interaction and other functions. A specific algorithm is used to transform the input path information into NC information. The controller converts the information into driving signal of a stepper motor or servo motor (pulse train) to control the cutter of X, Y, Z three axis of the engraving machine.

At the same time, milling processing can be used to engrave all kinds of graphic or 3D(three-dimensional) graphics words on the computer, so as to realize automatic carving.