Single-head Nesting CNC Machine

This nesting machine is mainly used for cutting, grooving, engraving, and drilling vertical holes on plates. Generally, friends who have just entered the furniture industry will choose this entry level CNC nesting router machine. Because it is the most basic nesting machine for sale and this kind of nesting CNC machine price is relatively cheap. Therefore, it is also named as the best nesting CNC machine for beginners or CNC nesting router for small business. The disadvantage of such a type of wood nesting CNC router machine is that there is only one machining spindle and can not realize complex nesting CNC projects. If you want to perform multiple processes, you need to manually change several different tools. Of course, very few processing plants now use this machine because of low production efficiency.

Multi-process CNC Nesting Machine

The multi-process nesting machine mainly refers to double process nesting CNC machine, three process nesting CNC machine, or four process nesting CNC router. What does the multi process mean? It means that the multi-functional nesting CNC machine is equipped with multiple machining spindles, which can continuously and uninterruptedly complete the work of cutting, slotting, punching, cutting, etc. No manual tool changing is required, and the processing speed is more than three times faster than ordinary single-head nesting machines. Manufacturers of a little scale and some newcomers with sufficient funds will choose this CNC machine.

The biggest highlight of the double-process nesting CNC machine is that a drilling package is added to the nesting machine. Therefore, this type of nesting CNC machine for sale includes a single spindle router with row drilling, a dual spindle CNC nesting machine with row drilling, automatic tool change spindle nesting CNC with row drilling. This type of nesting CNC can realize rapid vertical drilling and can automatically change the CNC drilling tool according to different hole positions. Therefore, the production efficiency of this type of CNC nesting cutting machine is very high.

ATC CNC Nesting Furniture Making Machine

Here are two type of ATC nesting CNC router for cabinet and furniture. One type is the linear ATC CNC nesting machines, and another is the ATC wood nesting machine with carousel tool magazine. And the automatic tool change spindle of this panel furniture CNC making machine is a top-brand high-power spindle with fast processing speed. The nesting machine bed is specially customized and has very high stability. This ATC wood nesting CNC machine is equipped with an independent tool changer magazine. Any tool can be placed in the magazine.The tool can be changed automatically according to different processing techniques during processing, which saves the time of manual tool changing. With the highest configuration, this type of nesting CNC router for sale is widely used for customers of various types of processing.

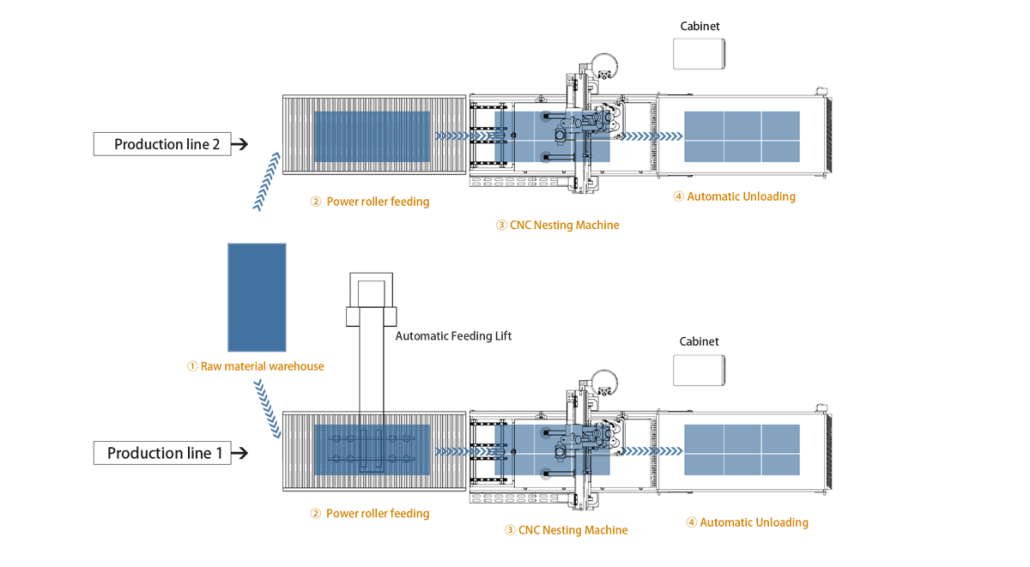

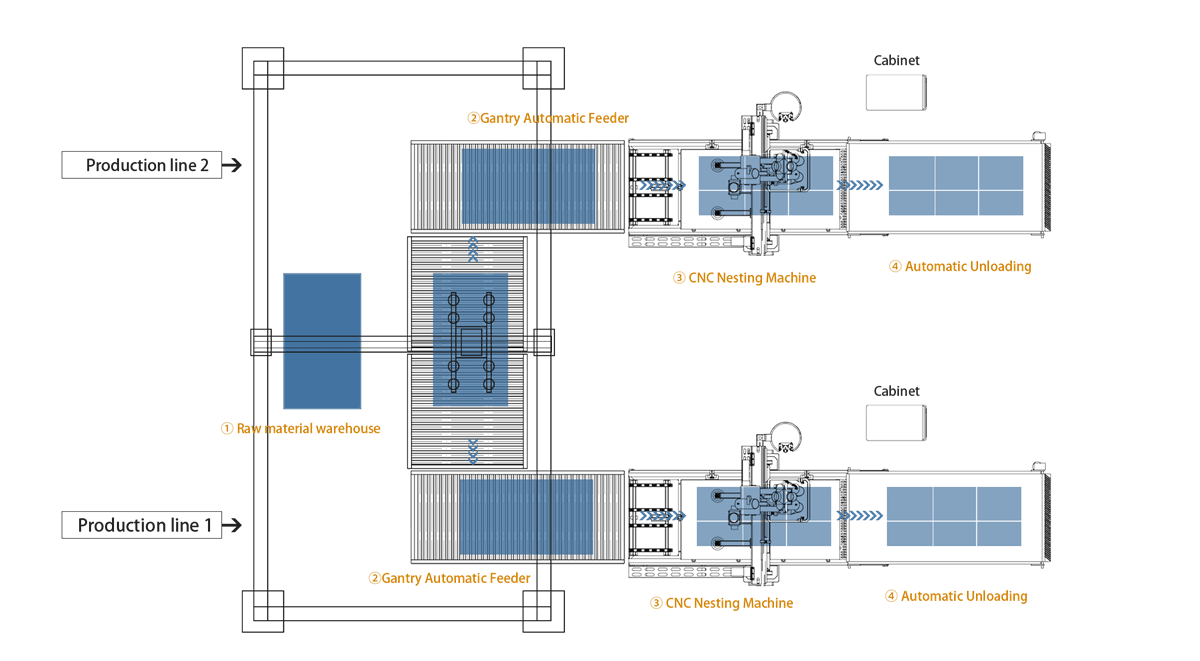

Multi-functional Nesting CNC Furniture Manufacturing Machines

Actually, Blue Elephant CNC Machinery Company provides many different types of nesting CNC machines for sale with many different functions, such as CNC wooden door lock making machine for sale, nesting CNC cabinet door making equipment with saw, auto nesting CNC feeding furniture making machine, automatic furniture making machine with drill, CNC nesting router machine with two worktables, labeling CNC nesting machine for sale, intelligent labeling and nesting cell, etc. They are all entry level nesting machines that added with different processing tools like CNC drill bits, saws, ATC spindles, worktables, labeling system, loading and unloading system, etc, to achieve more processes.