Automatic Electric Panel Saw

CNC woodworking beam panel saw machine,The electronic cutting saw has a wide range of uses. Because of its high rotation speed, the electronic cutting saw preprograms the size of the board to be cut, realizes automatic feeding, improves the production efficiency, and improves the work efficiency by 3 – 4 times compared with the ordinary board cutting machine.

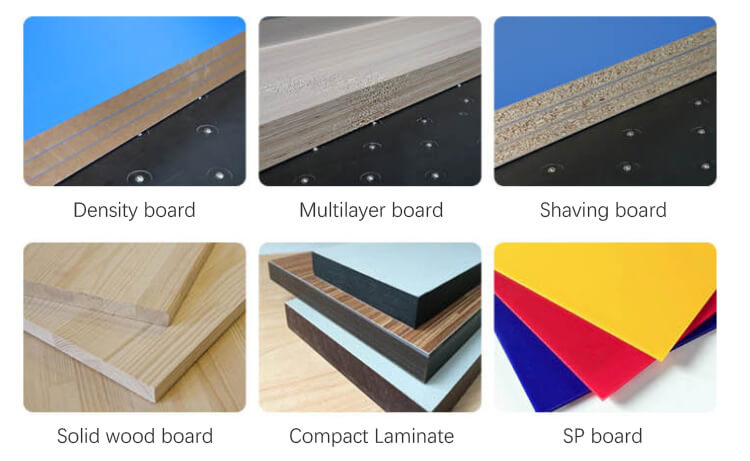

Processing Material: Plexiglass, light guide plate, circuit board, large core board, MDF board, wood-based board, artificial stone, aluminum-plastic board, MDF board, MDF, flower board, ABS board, PVC board, PS board, PET board, Grating plate, artificial leather, synthetic stone, solid wood and other materials are used. It can also be used to cut hardboards such as gypsum board and laminate flooring.

CNC Wood Panel Cutting Beam Saw Machine

Eletronical Wood Panel Cutting Saw Parameter

| Ind | Parameter |

| Model | IG-E27FG |

| Sawing length | 2800mm/3300mm/3800mm |

| Saw blade height | 100mm |

| Main saw blade diameter | Φ400mm |

| Main saw blade shaft diameter | Φ60mm |

| Main saw blade speed | 3910m/min |

| Slot saw blade diameter | Φ180mm |

| Slot saw blade shaft diameter | Φ30mm |

| Slot saw blade speed | 5860m/min |

| Sawing forward speed | 1-80m/min |

| Main motor | 13KW(Optional 15KW) |

| Sawing retreat speed (promise) | 1-80m/min |

| Saw car drive motor | 1.5KW |

| Total power | 20KW |

| Automatic feeding speed | 40m/min |

| Working pressure | 5-7kg/cm² |

| The height of the workbench from the ground |

900mm |

| Net weight | 4500kg/5500kg/6500kg |

| Machine installation size | 5300*5630*1750mm 5800*6100*1750mm 6300*6500*1750mm |

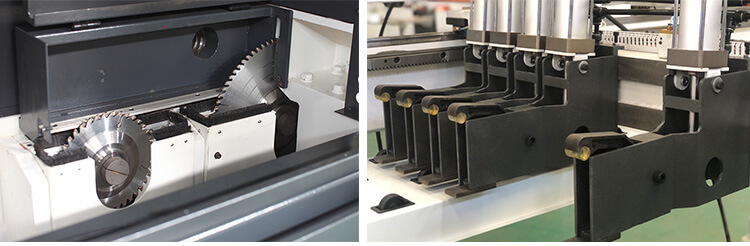

Saw blades

Screw lock type saw blade system, stable and easy to replace saw blades.

Feeding gripper

Gripe the panel steadily, highly reduce labor intensity, and improve production efficiency.

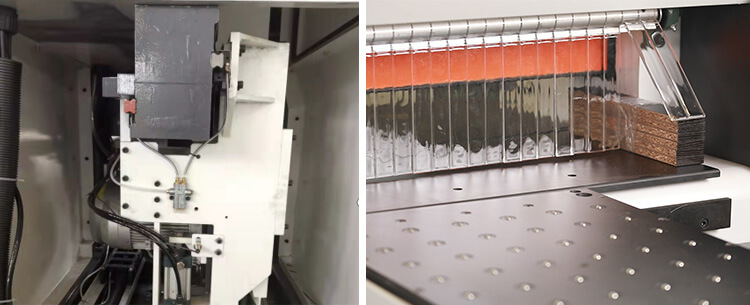

Air flotation bead table

The air cushion table adopts stainless steel balls, which can effectively reduce the friction between the workpiece and the steel balls and protect the plate.

PC control system

1. Easy operation, safety & reliable.

2. Which has complete operating hints and troubleshooting guide functions.

3. It’ s cutting plan can edit manually;can simulate or execute cutting plans.

Sawing motors

High precision and smooth operation, Multi-belt drive to ensure sawing accuracy.

Baffle Design

Before sawing, the baffle automatically falls down to prevent dust from splashing.

High Speed

This high speed computer beam saw is capable of cutting wooden panels with a maximum length of 3700mm. It features intelligent high-speed cutting, excellent precision, high stability and easy operation.

Application Of CNC Wood Panel Cutting Beam Saw Machine

This machine can be widely used for precision cutting of MDF, particle board, MDF,gypsum board, artificial stone, plexiglass, large core board, light guide plate, aluminum plate, aluminum plastic plate, circuit board, solid wood plate and other plates. It is suitable for processing all kinds of density board, particle board, ABS board, PVC board, plexiglass board and solid wood plate and other structures with similar hardness.

Application:

The electronic cutting saw has a wide range of uses. Because of its high rotation speed, the electronic cutting saw can be widely used in: precision casting of furniture factories, electrical appliances factories, garment factories, toy factories, hardware factories, etc.

Contact Us Today to Get Price!

1. According to the input plate width, cut the required plate and quickly return to the original working state.

2. Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

3. The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

4. Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy

Preparations:

- Clean all the tools and sundries on the computer panel saw before starting the machine.

- Check if the lubrication system, dust collection system, and cable connection of the panel saw machine are normal.

- Check if the main saw blade and auxiliary saw blade are in the same straight line. In case that the sawteeth are worn, replace the saw blade in time and pay attention to the rotating direction when replacing it.

- Run the panel saw machine idling for 2 minutes and start cutting work after every part works normally.

Operating:

- Check if the cutting saws of the panel dividing saw are at the home position first.

- Set the cutting parameters on the control panel according to your actual processing demands.

- Select the mechanical parameters, such as work mode, cutting speed, panel length, and width, on the control screen of the panel saw machine.

- Turn on the saw blades and draught fan of the panel saw machine and start the cycle mode.

- Put the wooden panels in position and start the cutting work. The CNC beam saw can input the required sizes of 10 groups of different raw materials at a time until all the raw materials are cut.

- Inspect the first finished product to see if it meets the processing standards based on the drawings or technical requirements.You can start the mass cutting work if it meets all standards.

After operation:

- Cut off the power supply of the computer panel saw machine.

- Clean the waste and chips on the computer beam saw timely.

- Supplement the lubricant and replace the worn saw blades in time.

This intelligent computer beam saw is good at cutting wooden panels in panel furniture manufacturing industry. It adopts the industrial computer control, which has an advanced but easy-to-operate man-machine interface.