Wood edge banding machines come in various sizes and configurations, ranging from small, manually operated machines to large, fully automated systems.

Wood edge banding machines are commonly used in the furniture manufacturing industry, cabinetmaking, and woodworking workshops. They automate the process of applying edge banding, making it faster and more efficient compared to manual methods.

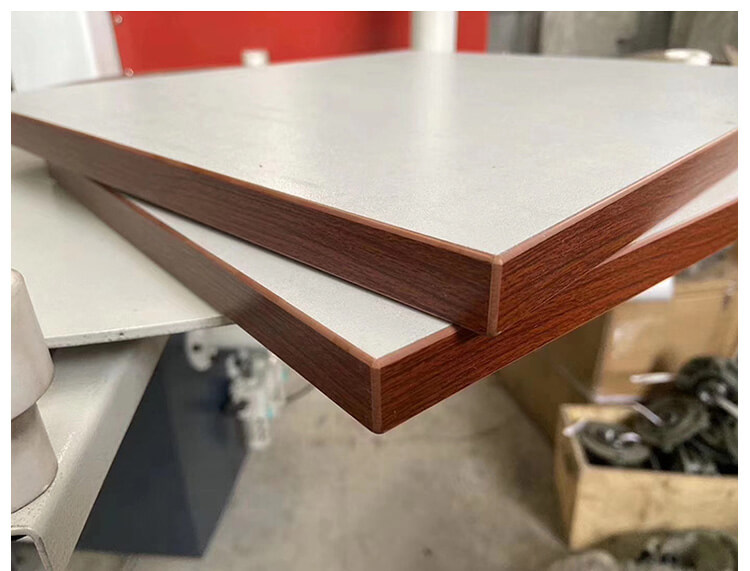

As we all know, cabinet edge banding plays an important role in furniture production. Good edge banding makes the cabinets more beautiful and smoother. Besides, it can effectively control the release of formaldehyde in the panel, making our home more environmentally friendly. Therefore, the edge bander is an indispensable furniture making machine for the whole panel furniture production line.

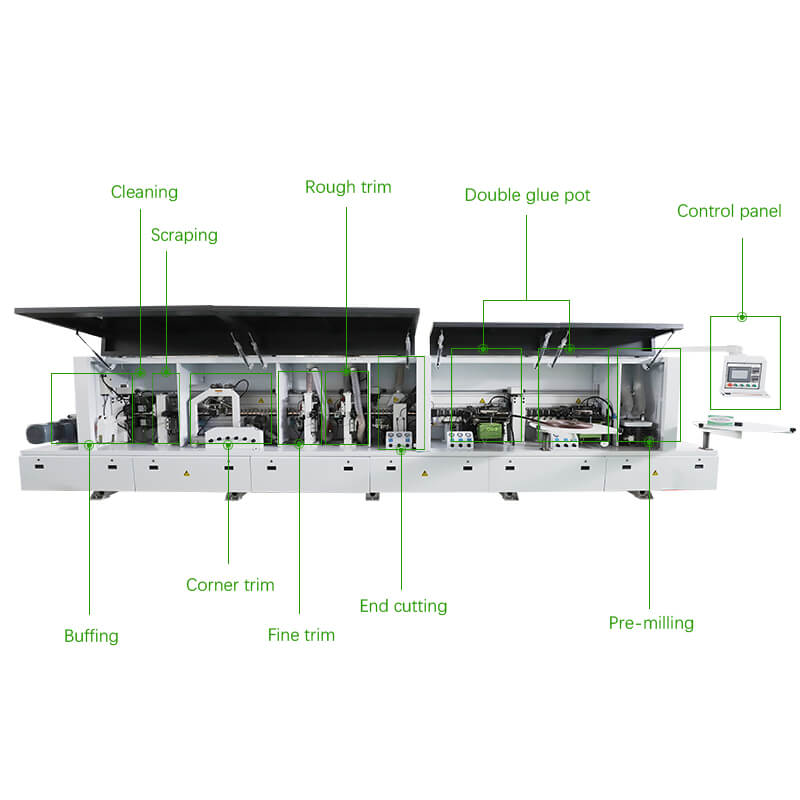

A banding machine for cabinet edges mainly includes the main structure, multiple processing units, and the control system. The processing units include the pre-milling unit, banding tape conveying unit, banding unit, cutting unit, trimming unit, rounding unit, scraping unit, and polishing unit. Each of these units corresponds to one separate function.

Relying on the advantages of high automation, stable operation, reliability, durability, and moderate price, edge banding machines are especially suitable for large and medium-sized furniture, cabinets, and other panel furniture manufacturers.

An edgebanding machine, also known as an edgebander, is a specialized woodworking machine used to apply edgebanding materials to the edges of panels, such as plywood, particleboard, or MDF (medium-density fiberboard). Edgebanding is commonly used to provide a finished look, enhance durability, and protect the exposed edges of these panels.

Edgebanding machines are widely used in industries such as furniture manufacturing, cabinetry, woodworking shops, and interior design. They offer efficient and precise edgebanding processes, reducing manual labor and ensuring consistent results. It’s important to follow proper safety protocols and manufacturer guidelines when operating an edgebanding machine.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.