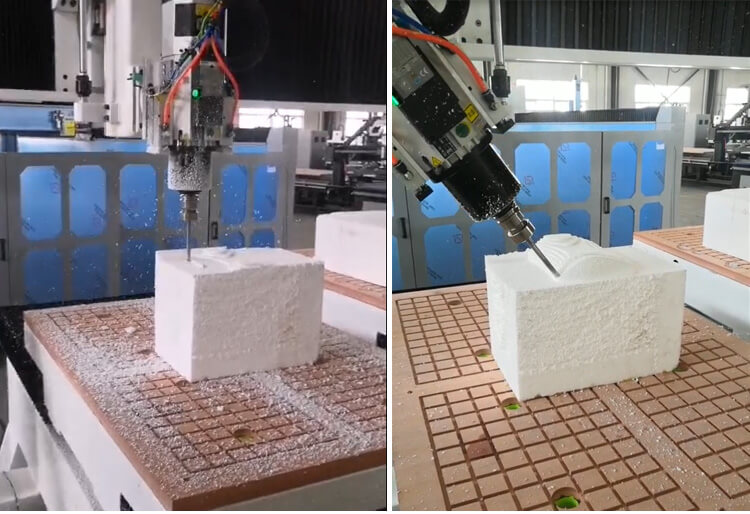

Model foam CNC cutting machines offer high precision and accuracy, allowing for intricate and detailed cuts. They can reproduce complex shapes, curves, and contours with consistency, ensuring the quality and precision of foam models.

These machines are ideal for creating custom foam models and prototypes. By using CAD software and converting designs into machine-readable instructions, users can quickly and accurately produce foam models based on their specific requirements. This enables designers and engineers to iterate and refine their designs before moving to full-scale production.

Model foam CNC cutting machines automate the cutting process, significantly reducing production time compared to manual cutting methods. They can cut multiple foam pieces simultaneously, improving efficiency and productivity in model making and prototyping workflows.

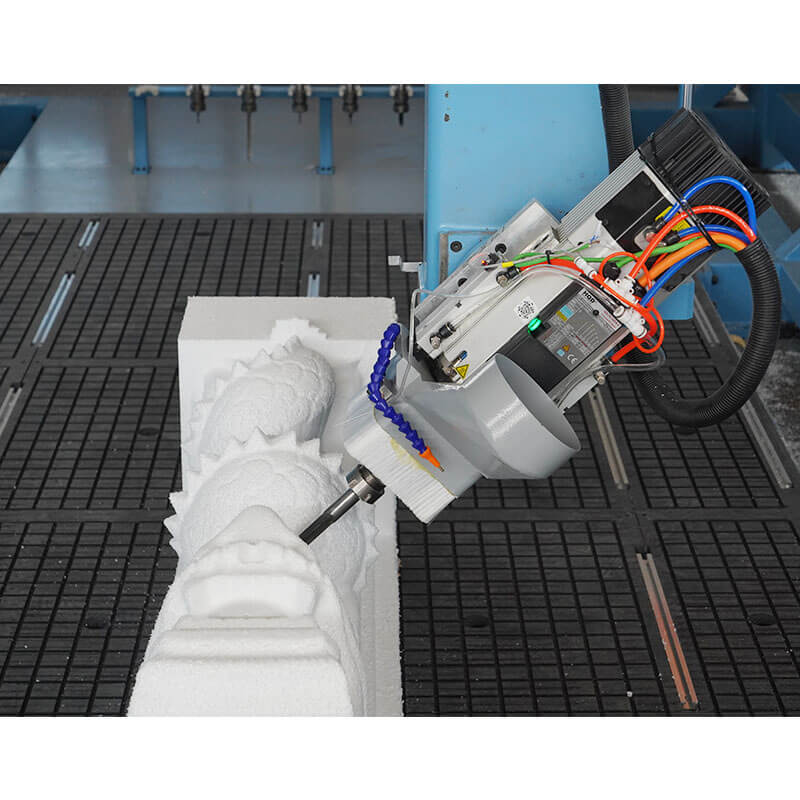

In addition to cutting foam, some model foam CNC cutting machines can be equipped with additional tools for performing tasks such as engraving, drilling, and chamfering. This versatility allows for a wider range of applications and enables users to create more complex and multi-functional foam models.

Model foam CNC cutting machine often come with user-friendly software interfaces that make programming and operation easier. With intuitive software, users can import or create their designs, define toolpaths, and generate the necessary G-code instructions for the machine to execute.

Features and advantages of the EPS foam CNC router

- Adopting original cross-beam triangle balanced guide rail structure and Z-axis balance auxiliary device, it can ensure fast and stable processing of multi-curved surfaces.

- It adopts Taiwan’s integrated operating system, which is easy to operate and powerful, and has online simulation and online monitoring functions to ensure safe and efficient processing.

- Processing size can be customized according to processing needs. And whose Z-axis travel can be up to 2.2 meters and this machine can be upgraded to a 5 axis CNC machine.

- Adopting automatic oil lubrication system, it is easier to operate and maintain during the processing.

- Adopting the high-power servo drive system in conjunction with the top accessories such as the Italian spindle to make the equipment stable and durable.

- Intelligent processing cross-border protection function can prevent mechanical collision caused by excessive design file processing.

- Diversified control can separately control the processing speed, idling speed, and cutting speed, which greatly improves the quality and processing efficiency of processed products.

- With the functions of continuous break point carving, power recovery, processing time prediction, it can be handy regardless of vigorous cutting or fine carving.

- Extremely humanized design combined with ergonomic design makes your operation easier.

- Regardless of whether the operation panel is highly designed or modularized, it is to make you have a better user experience.

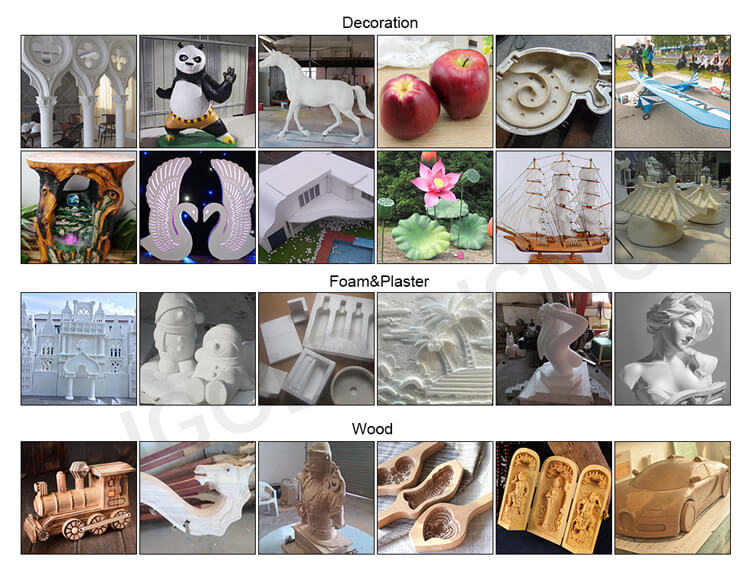

Foam Cutter Machine Applications

Hot applications include:

Carving all kinds of non-metal materials processing such as foam, lost foam, automobile foam mold, yacht mold, large ship wooden mold, cast wooden mold, engineering plastic materials, aviation wooden mold, propeller, train wooden mold, etc.

>Foam processing of automotive stamping molds, casting wood molds, automotive interiors, processing of engineering plastic materials;

>Other industry molds: electrical appliance molds, lighting molds, ceramic sanitary ware, three-dimensional curved surfaces for large musical instruments, instrument molds, home appliance molds, air-conditioning molds, automotive molds, automotive interior molds, etc.

Why choose the EPS foam CNC router?

Hand-tool working greatly affects the efficiency and quality of mold making. CNC have the advantages of uniform margin, fast processing speed, and high processing quality, this CNC foam cutting machine is widely used in many industries, which not only improves the quality of mold castings but also shortens the mold production cycle.

Type of foam CNC cutting machines

Hot Wire Foam Cutter

This type of cutting tool uses a heated wire to melt and cut through foam materials. It is particularly effective for cutting through expanded polystyrene (EPS) foam, which is commonly used for architectural models and set designs.

Oscillating Knife Cutter

An oscillating knife, also known as a tangential knife, uses a reciprocating motion to cut through foam. It is suitable for cutting various types of foam, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane foam. Oscillating knives are versatile and can handle intricate patterns and complex shapes.

Some model foam CNC cutting machines may also have the capability to use router bits, which are typically used for cutting denser foam materials or for performing other machining operations, such as engraving or chamfering.

Laser cut foam

The laser beam has a narrow kerf width, resulting in clean and accurate cuts with minimal material waste. This precision makes laser cutting ideal for creating complex shapes, fine details, and intricate patterns in foam models.Laser cutting is a fast and efficient method for cutting foam. The cutting process is automated and can be completed in a fraction of the time required for manual cutting methods. This makes laser cutting suitable for both small-scale projects and large-scale production runs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.