A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

CNC Router Wood Cutting Machine

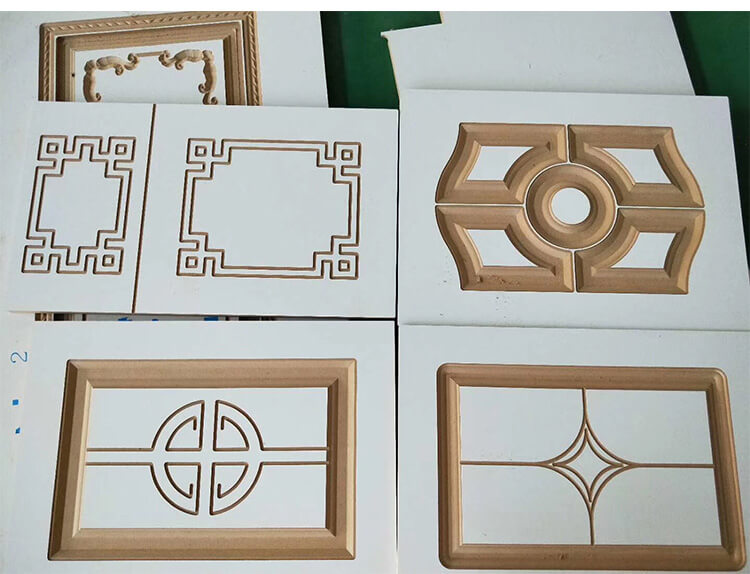

When it comes to wood cutting, CNC routers offer several advantages over traditional manual woodworking techniques. These machines are capable of cutting intricate designs, creating complex shapes, and achieving consistent precision, all while reducing the risk of human error. CNC routers can be used for tasks such as carving, engraving, drilling, and cutting out shapes from wood plans.

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

The most used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft. A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations.

Features CNC routers for wood cutting

- The cutting bed is a flat surface where the wood material is placed for cutting. It can be made of various materials such as aluminum or steel and may include a vacuum system to hold the workpiece in place.

- The spindle or router is the cutting tool mounted on the CNC machine. It rotates at high speeds and can have different cutting bits or tools depending on the desired cutting operation.

- The control system comprises a computer and software that converts the CAD designs into machine-readable instructions. The software controls the movement of the cutting tool along the specified paths.

- CNC routers have motors and drive systems that move the cutting tool along the X, Y, and Z axes according to the instructions from the control system. These motors and drives enable precise and accurate movements.

- Wood cutting can generate a significant amount of dust and debris. Many CNC routers include a dust collection system that helps keep the work area clean and maintain better visibility during the cutting process.

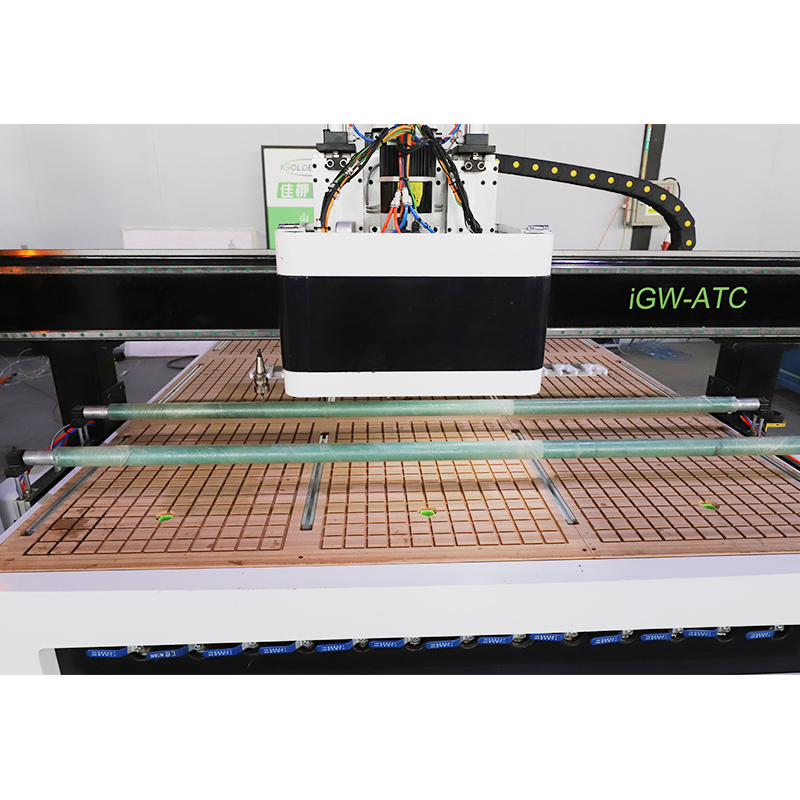

Automatic Tool Changer Wood Cutting Machine

Automatic Tool Changer is a device for transferring, loading and unloading tools between the spindle and the tool magazine. Automatic Tool Changer is the full name of ATC in CNC machining.

Automatic tool changer kits drive the CNC machine with continuous working, that is, after each process is completed, the new tool used in the next process is automatically changed to the spindle, and the spindle picks up the tool, the exchange of tools is generally completed by the coordinated action of the manipulator, magazine and spindle.

Compared with multi spindle CNC routers, ATC only needs one spindle in the headstock, the spindle components have sufficient rigidity to meet the requirements of various precision machining. In addition, the tool magazine can store a large number of tools for multi-step machining of complex parts, which can significantly improve the adaptability and machining efficiency of the machine tools. The ATC system consists of two parts: a tool magazine and an automatic tool change device. It has two major advantages: the first is that only one spindle is reserved, which is beneficial to simplify the structure of the spindle and improve the rigidity of the spindle; the second is that a large number of router bits with different types and functions can be stored in the library, which is convenient complete various complex and multi-step processing procedures.

Whether you are a craft carpenter or a professional woodworker, you can easily find your next CNC router at IGOLDENCNC to automate your woodworking projects. Its user-friendliness, ease of use and multi-function make it easy for you to benefit and profit. Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

Other woodworking cutting machines

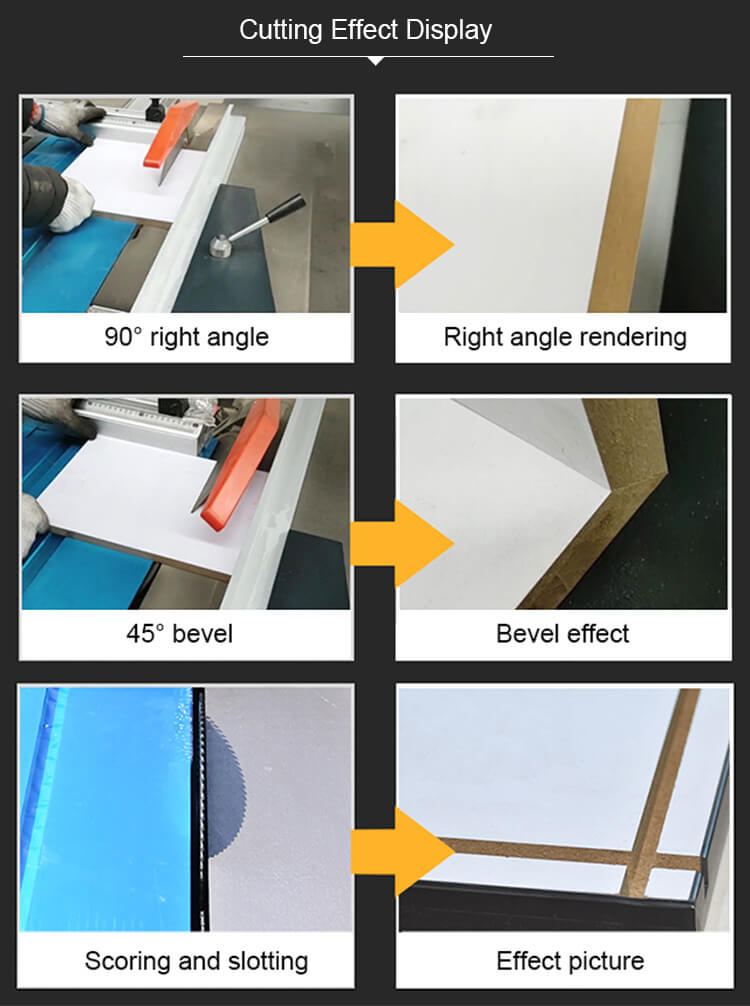

Electronic CNC Wood Saw Cutting Machine

Computer CNC beam saw is a computer-controlled and intelligent wooden panel cutting machinery. It can cut multiple layers of wooden panels with the thickness up to 100mm at the same time with high efficiency and excellent accuracy.

CNC Wood Saw Cutting Machine Application:

The electronic cutting saw has a wide range of uses. Because of its high rotation speed, the electronic cutting saw can be widely used in: precision casting of furniture factories, electrical appliances factories, garment factories, toy factories, hardware factories, etc.

CNC Wood Saw Cutting Machine Processing Material:

Plexiglass, light guide plate, circuit board, large core board, MDF board, wood-based board, artificial stone, aluminum-plastic board, MDF board, MDF, flower board, ABS board, PVC board, PS board, PET board, Grating plate, artificial leather, synthetic stone, solid wood and other materials are used. It can also be used to cut hardboards such as gypsum board and laminate flooring.

CNC Wood Saw Cutting Machine Machine Features:

1. According to the input plate width, cut the required plate and quickly return to the original working state.

2. Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

3. The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

4. Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy

Sliding Table Saw Machine

A decent industrial CNC for me. I’m a high-end furniture maker and need more precise power tools to support the type of work that I do. The moving table makes this machine work with higher precision. Also, the automated tool changer spindle kit is professional for cabinets making and wood doors making, as well as some home decors. The software is powerful for my business, it’s a breeze to create tool path and export G-code once you are proficient in CAD design. All in all, I’m satisfied with its overall capability and performance.

Very good machine and service