ATC CNC wood cutter router machine, it can have many advantages such as improving production efficiency, simplifying the production process, and producing more products. This CNC router furniture machine can process medium density fiberboard, particle board, particle board, wood, oriented strand board, melamine board, plywood, acrylic, plastic, soft metal and many other different materials.

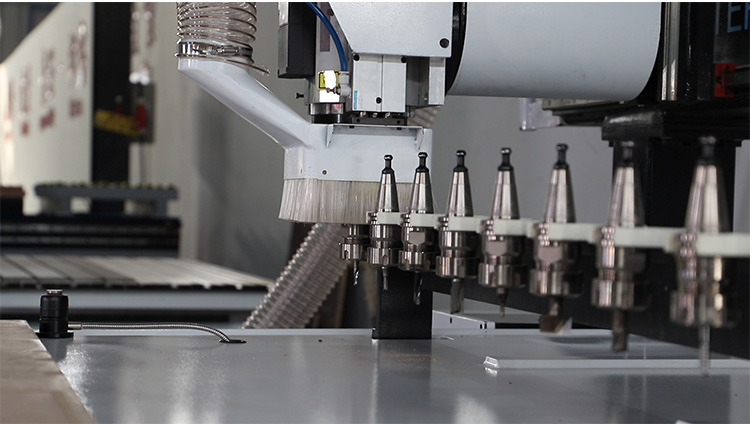

9KW Air-cooled Tool Change Spindle And Finished Material Pushing System

This atc spindle CNC router is equipped with a 9kw high-frequency air-cooled spindle as standard. This spindle has fast processing speed, high processing accuracy, does not require maintenance, and has a long service life. And this advanced CNC wood cutter machine is also equipped with a finished material pushing system. When the workpiece is processed, the cut material will be pushed to the front of the machine, and the vacuum brush at the back of the beam will stay on the table. The small sawdust is sucked away. Prevent scum from affecting the vacuum suction function. Make the machine vacuum suction firmer.

It can be equipped with different tool library and quantity according to different production process, and other options can also be added, such as spindle swing, side rotating shaft, etc.

CNC Router Machines with ATC Spindle Features and Advantages

- This ATC CNC Router adopts a new generation bus controller system Syntec controller with better stable performance, Japanese YASKAWA AC Servo motor, and driver, HSD air-cooled automatic tool change spindle from Italy, Delta inverter from Taiwan.

- Automatic tool change system with 8, 12, and 16 tool magazines. Saving machining time compared with traditional machines.

- Recommend automatic pusher function for this CNC Router Machine which can dock the automatic loading and unloading platform, reduce labor cost, and save loading and unloading time.

- Intelligent processing of the out-of-bounds protection function prevents over-machining caused by mechanical collisions.

- The ATC CNC Cutting machine can be equipped with an independent pressure roller, which effectively solves the problem of board moving when the machine is on cutting work

- Applications of this ATC Wood CNC Router: sofa keel cutting, wooden doors, cabinet doors, cabinet cabinets, mold industry, advertising industry, etc.

- Competitive factory direct price and one year warranty.

Application Industries:

- Wooden furniture industry: solid wood and composite door, cupboard door, sliding door, paint door, paint door, flexible packaging, plate carving, wood carving, machining, antique mahogany furniture, solid wood panel furniture murals carved, etc;

- Wooden crafts industry: clock clock frame, picture frame, calligraphy CARDS, electrical appliances, sports equipment, thin aluminum plate engraving mesa sculpture;

- Advertising industry: acrylic, PVC, MDF, artificial stone, organic glass, plastic, copper, aluminum and other soft sheet metal.

Why to choose the ATC CNC Machine?

First, high productivity. Equipped with automatic tool changing device, which can meet the tool changing requirements during processing without manual participation. With simple and easy operation mode to learn, which can help users quickly grasp the use of methods and greatly improve production efficiency.

Second, imported spare parts.

- Adopting the automatic tool changing spindle, it has the advantages of good starting performance, fast processing speed, large torque and high processing efficiency.

- Adopting Italy HSD spindle motor, and spindle bearings with high-precision ceramic bearings, it has the advantages of low noise and long service life.

- Equipped with the imported high torque servo motor, it has the advantages of low noise, fast speed and high positioning accuracy. Equipped with a unique tool changing device and a dedicated tool setting table, it can realize automatic tool changing without intermittent with fast tool changing speed, and can accurately compensate for tool length errors.

- Adopting Taiwan linear guide and ball screw, it has the advantages of high bearing capacity and accurate cutting.

Third, good software compatibility. Adopting open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / Castmate / Wentai, to ensure the realization of various design functions.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.