ATC CNC represents one of the most significant productivity innovations in computer-controlled machining, yet many people encountering this term remain unclear about what it means and why it matters. At #iGoldenCNC, we help customers understand how Automatic Tool Change (ATC) technology transforms CNC capabilities, dramatically improving efficiency for operations requiring multiple cutting tools. This comprehensive guide explains ATC fundamentals, how the technology works, its advantages, applications, and when investing in ATC capability makes business sense.

ATC CNC

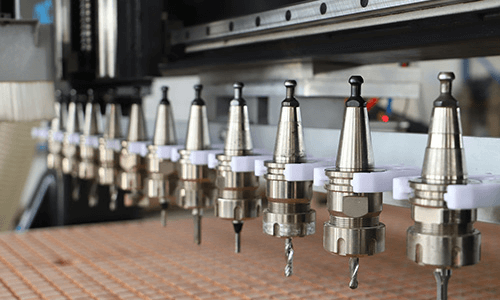

ATC stands for Automatic Tool Change or Automatic Tool Changer. An ATC CNC machine is a computer-controlled router, machining center, or mill equipped with a system that automatically exchanges cutting tools during operation without human intervention. The machine stores multiple tools—typically 4 to 24 different bits, end mills, or cutters—in a carousel, magazine, or rack, selecting and installing the appropriate tool for each operation based on programmed instructions.

The ATC system generally consists of a tool magazine and an automatic tool changing mechanism, allowing storage of multiple router bits for multi-step machining of complex parts. By using only a single spindle, ATC routers simplify spindle structure, improve rigidity, and maintain high precision. Automated tool changers reduce mechanical movement, shorten tool-change times, and provide flexible layouts for high-efficiency production in industrial and small workshop settings.

Unlike traditional CNC routers that require manual bit changes, ATC systems enable continuous, multi-tool operations for woodworking, cabinet making, furniture production, plywood, MDF, aluminum, acrylic, and other materials.

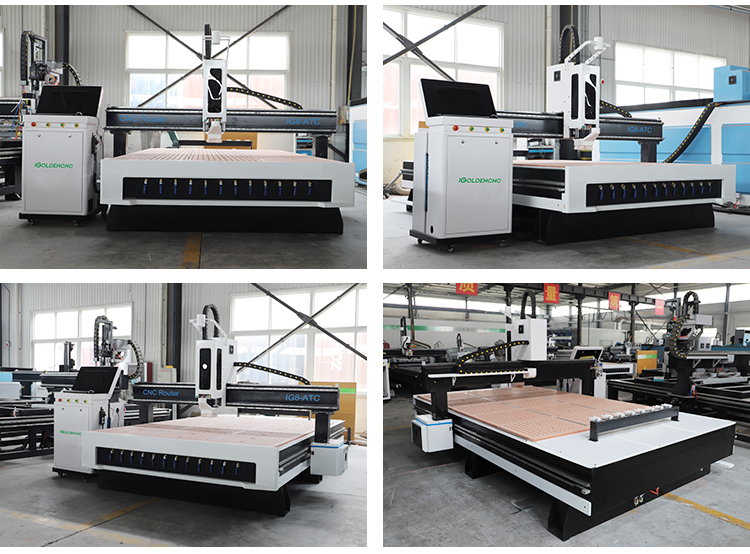

ATC CNC Machines

How ATC Systems Work

Tool Storage: Tools mount in holders inserted into a tool carousel, linear magazine, or storage rack. Each position is numbered, and the CNC control system knows which tool occupies each location. Common configurations include 8-tool, 12-tool, 16-tool, and 24-tool capacity, though some industrial systems accommodate 40+ tools.

Tool Identification: The CNC program specifies which tool performs each operation—”use tool #3 for roughing,” “use tool #7 for detail work,” “use tool #12 for drilling.” The control system tracks which tool is currently in the spindle and which tools are available in the magazine.

Automatic Exchange Process: When programming requires a different tool, the machine initiates the tool change sequence automatically:

- The spindle moves to a designated tool change position (usually a safe location away from workpiece and fixtures) .

- The spindle clamp releases, and the current tool either drops into a waiting tool holder or is extracted by the tool changer mechanism .

- The carousel/magazine rotates or the linear changer moves, positioning the next required tool .

- The new tool inserts into the spindle, the spindle clamp engages securing the tool, and the machine resumes cutting operations with the new tool

This entire sequence typically completes in 3-8 seconds depending on system sophistication and tool magazine configuration.

Software Integration: CAM (Computer-Aided Manufacturing) software generates programs specifying tool sequences, automatically inserting tool change commands at appropriate points. Operators simply load tools into designated magazine positions matching the program’s tool assignments.

Features & Advantages of ATC CNC Machine

• High-power ATC spindle with large torque for fast, precise routing, milling, and machining.

• High-torque servo motors ensure low noise, high speed, and accurate positioning.

• Flexible tool magazines, standard 8 tools, customizable for larger capacity.

• Enables multi-material processing: wood, MDF, plywood, aluminum, acrylic, and plastics.

• Short tool-change time (typically 2–8 seconds), improving production efficiency.

• Ideal for furniture manufacturers, cabinet making, plywood workshops, and industrial production lines.

Costs of ATC CNC Router Machine

The price of an ATC CNC router machine varies based on working area, spindle power, number of axes, and features:

• Entry-level hobby ATC CNC routers: around $12,000

• Industrial ATC CNC routers with larger worktables, advanced spindles, and multiple axes: $25,000–$100,000+

• Average cost for most commercial ATC CNC routers: approximately $16,000

For upgrading an existing ordinary CNC router with an ATC kit, expect an additional $3,000–$8,000 depending on specifications. Investing in an ATC system allows faster, more precise multi-tool operations for woodworking, cabinet making, furniture, MDF, plywood, and aluminum production, significantly increasing productivity and reducing downtime.

Specifications of iGOLDEN ATC CNC Router Machine

| Specification | Details |

|---|---|

| Brand | iGOLDEN |

| Table Sizes | 4′ x 4′, 4′ x 6′, 4′ x 8′, 5′ x 10′, 6′ x 12′ |

| Axis | 3 Axis, 4th Axis, 4 Axis, 5 Axis |

| Capability | 2D Machining, 2.5D Machining, 3D Machining, Woodworking, Routing, Cutting, Machining, Milling, Drilling, Grooving, CNC Furniture Making, Cabinet Making |

| Materials | Wood, MDF, Plywood, Aluminum, Acrylic, Plastics, Brass, Copper, Foam, Stone, Stainless Steel |

| Types | Entry-Level Hobby CNC Machines, Industrial CNC Routers, ATC CNC Router Machines, CNC Machines for Cabinet Making, Furniture & Woodworking CNC Machines |

| Software Compatibility | ArtCAM, Type3, Cabinet Vision, CorelDraw, UG, Solidworks, MeshCAM, AlphaCAM, UcanCAM, MasterCAM, CASmate, PowerMILL, Fusion360, Aspire, AutoCAD, Autodesk Inventor, Alibre, Rhinoceros 3D |

| Controller | OSAI, Syntec, LNC, Mach3, Mach4 |

| Price Range | $6,000 – $110,000 |

| OEM Service | Customizable X, Y, Z Axis Working Area |

| Optional Parts | Dust Collector, Rotary Device, Vacuum Pump, Servo Motors, Cooling System, HSK or Colombo Spindle, Automatic Tool Changer Magazine |

Types of ATC CNC Router Machines

ATC (Automatic Tool Changer) CNC Router Machines can be classified into three common types, designed to meet different machining needs, tool capacities, and production environments:

1. Linear Type ATC

Linear ATC systems, also called in-line tool changers, are ideal for magazines holding 4 to 12 tools. They provide fast tool change, high repeatability, and are easy to operate. This type is widely used in woodworking, MDF and plywood cutting, and small- to medium-sized cabinet and furniture production.

2. Drum Type ATC

Drum type, also known as CTM or disc type ATC, uses a rotary magazine to store 8 to 20 tools. It allows rapid automatic tool changes during multi-step machining processes and is suitable for industrial CNC woodworking, aluminum cutting, and furniture manufacturing. Drum type ATC is popular for high-efficiency routing, cutting, and milling operations.

3. Chain Type ATC

Chain type ATC is designed for vertical CNC machines with slower tool changing speeds but a very large tool capacity (30+ tools). It is ideal for heavy-duty industrial CNC routers, multi-material machining, and large-scale production of cabinets, furniture panels, and composite materials. This type provides the best flexibility and tool carrying capacity for complex multi-step machining.

How to Change Tools in ATC CNC Router Machines?

1. Rotary Tool Holder (Rotary Post) Method

Rotary tool holders are one of the simplest ATC solutions, often used in CNC lathes or compact router machines. The holder can be square, hexagonal, or disc type, holding 4–6+ tools. Bits are automatically changed according to CNC commands, ensuring high precision. With a robust structure, the rotary holder withstands cutting resistance during rough machining, maintaining repeat positioning accuracy typically between 0.001–0.005mm. The tool change sequence involves lifting, indexing, and pressing the holder. This method is suitable for small to medium-sized wood, MDF, plywood, and aluminum machining.

2. Spindle Head Changing Method

Spindle head tool changers use a turret tool magazine, available in horizontal or vertical designs. Each spindle head comes preloaded with the required tools. When a tool change command is triggered, the turret indexes to position the appropriate tool, engaging only the spindle in use. This automated process reduces manual intervention, saves time, and improves reliability. Turret spindle heads are suitable for ATC routers with limited tool numbers and low- to medium-precision processes.

3. Automatic Tool Changing System with Magazine

For multi-step or complex machining, most ATC CNC routers use automatic tool changers with a tool magazine. The system includes a magazine and tool changing mechanism, enabling simultaneous loading and unloading of bits. Tools are preinstalled in standard holders, pre-adjusted, and stored in the magazine—typically mounted on the side or above the headstock. The ATC system ensures only one spindle is needed while supporting a large number of tools, increasing efficiency for furniture, cabinetry, and composite material production. The magazine-based ATC is ideal for industrial-grade CNC woodworking, aluminum routing, and multi-material manufacturing.

How to Choose Tool Magazine and Router Bits for ATC CNC Router Machines?

1. Tool Magazine Types for ATC CNC Routers

ATC CNC routers use tool magazines to store multiple router bits, enabling automatic tool changes during multi-step operations. There are three common types:

• Disc (Rotary) Tool Magazine:

Suitable for 4–12 tools. Bits are aligned with the spindle and exchanged via a simple rotation mechanism. Advantages: simple structure, reliable, low cost. Limitation: longer tool change time, best for small- to medium-capacity machining centers.

• Chain Tool Magazine:

Designed for machines requiring larger tool storage (15–50+ bits). Features a compact layout with high capacity, allowing more tools to be stored and exchanged efficiently. Ideal for industrial CNC routers used in furniture, cabinetry, and multi-material processing.

• Linear Tool Magazine:

Inline type magazine for 6–24 tools. Fast, precise, and easy to use. Works well in 3 axis and 4 axis ATC CNC router machines for wood, MDF, aluminum, and plastic materials.

2. Tool Selection Methods

Before machining, the system selects the appropriate bit from the magazine. Common methods include:

Sequential Selection: Bits are used in order according to the programmed process. Simple and reliable, suitable for small- to medium-sized CNC operations.

Arbitrary (Random) Selection: Any tool can be chosen based on the process requirement. This method supports large-capacity magazines and multiple workpiece types, offering greater flexibility for industrial ATC CNC routers.

3. Tool Coding Methods

Tool coding ensures each bit is accurately tracked and reused across different processes:

Binary/Code Bar Method: A code bar on the tool or holder identifies each bit.

Memory-Based System: The PLC stores the number and position of each holder in the magazine, allowing the system to pick and return bits automatically. This method improves efficiency, reduces errors, and is widely used in industrial ATC routers.

4. Key Advantages for Users

Supports automatic, high-speed tool changes for multi-step processes.

Increases machining efficiency and precision for wood, MDF, plywood, aluminum, and other materials.

Reduces manual intervention, downtime, and errors during production.

Flexible magazine options (disc, chain, linear) to fit different business needs and production scales.

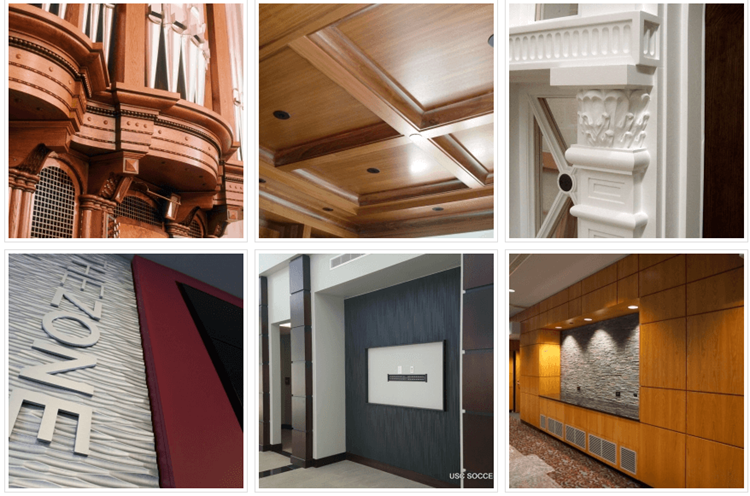

Applications of ATC CNC Router Machines

ATC CNC routers are engineered for precision, high-speed, multi-tool machining across a wide range of industries. They are ideal for processing wood, MDF, plywood, aluminum, plastic, acrylic, and other non-metallic or semi-metallic materials, enabling businesses to improve efficiency, consistency, and production scale.

1. Woodworking & Cabinetry

Applications: Home doors, 3D wave board machining, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, decorative panels, computer desks, and custom panel furniture.

Benefits: Enables complex cutting, sculpting, drilling, and grooving in a single setup, reducing manual labor and production time.

2. Mold & Prototype Making

Applications: Metal molds (copper, aluminum, iron), non-metal molds (wood, plastic, PVC, stone).

Benefits: High rigidity and accuracy allow precise mold shaping, reducing errors in multi-step machining processes.

3. Advertising, Signage & Hobbyist Projects

Applications: Acrylic cutting, sign making, logo cutting, lettering, blister molding, and decorative designs.

Benefits: Supports intricate, multi-material designs with consistent tool-change speed and high repeatability, perfect for commercial and craft applications.

4. Industrial Manufacturing & Artistic Fabrication

Applications: Shadow sculptures, relief carvings, musical instrument shells, precision instrument components, and specialty industrial parts.

Benefits: Large-capacity ATC systems and multi-axis capabilities enable complex, high-volume production for both functional and decorative industrial projects.

Troubleshooting and Maintenance

ATC CNC routers are high-performance, fully automated machines designed for multi-tool, multi-material operations. While their precision and throughput surpass standard CNC machines, regular inspection, maintenance, and fault diagnosis are essential to ensure consistent performance and longevity. The troubleshooting methods for ATC CNC routers differ from conventional CNC machines due to their integrated automatic tool changer systems, servo drives, and multi-axis configurations.

1. Machine Operation Inspection

Monitor the actual operation of the router to identify malfunctions. Check hydraulic and pneumatic components, the ATC tool changer, rotary tables, fixtures, and transmission systems. Observing motion and response can help trace the source of operational issues.

2. System State Analysis

Use the CNC control interface to review diagnostic data, status values, and error codes. For instance, if the spindle fails to return to the reference point correctly, checking axis status and system parameters can pinpoint the root cause.

3. CNC Program Verification

Compile and run test programs to check linear positioning, circular interpolation, thread cutting, canned cycles, and user macro programs. This method verifies the machine’s operational accuracy and helps isolate programming-related faults.

4. Instrument-Based Inspection

Utilize standard electrical testing instruments to measure AC/DC voltage, phase signals, and pulse outputs. This method helps identify issues in power supply, servo systems, or electronic components.

5. CNC System Self-Diagnosis

Modern ATC CNC routers include self-diagnostic features in the control system. Functions such as power-on self-test, online monitoring, and offline hardware testing can automatically detect and report issues in the spindle, servo motors, tool changer, and other critical components, allowing for quick maintenance decisions.

Maintenance Tips:

• Regularly inspect and lubricate the ATC tool changer, linear guides, and ball screws.

• Check spindle runout and tool clamping integrity to maintain machining precision.

• Ensure pneumatic and hydraulic systems are free from leaks and operating at correct pressures.

• Keep the machine clean from dust and debris to prevent sensor or mechanical blockages.

Conclusion

ATC CNC technology transforms computer-controlled machining from single-tool operations requiring frequent manual intervention into sophisticated automated manufacturing capable of complex multi-tool processes without human involvement. The productivity advantages, capability expansion, and labor efficiency gains make ATC invaluable for operations with appropriate application mixes and production volumes. Understanding what ATC is, how it works, and when it justifies investment helps you make informed decisions about whether this technology should be part of your CNC equipment specification. Partner with iGolden to explore whether ATC capability can transform your manufacturing efficiency and position your operation for sustained competitive success.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.