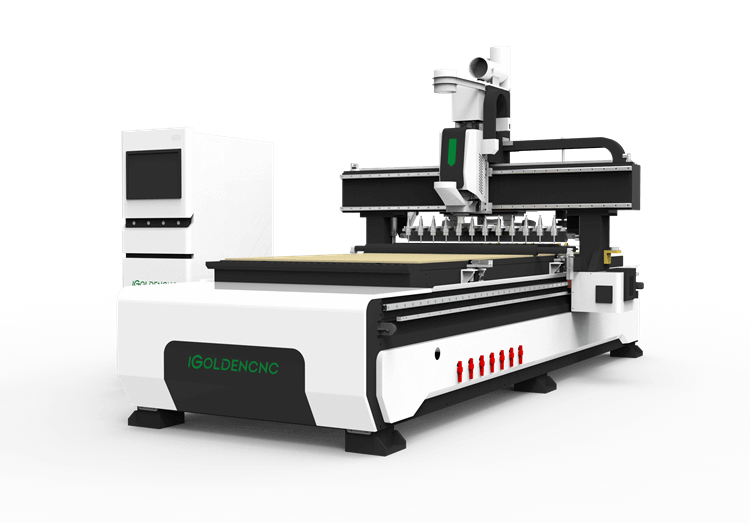

If you are involved in woodworking, furniture production, or interior decoration, you’ve probably heard about CNC wood cutting machines. These intelligent machines can cut, engrave, and carve wood with incredible accuracy and speed, helping thousands of workshops move from traditional manual methods to efficient, automated production. Among the reliable brands in this field, iGoldencnc has become a trusted name, offering machines that balance performance, quality, and price. But one common question for first-time buyers is: how much does a CNC wood cutting machine cost?

Understanding the Basics of CNC Wood Cutting Machines

Before talking about numbers, it’s worth clarifying what you are actually investing in. A CNC wood cutting machine is powered by a computer numerical control (CNC) system. That means the shapes or designs you create on software are sent directly to the machine, which then cuts or engraves the design perfectly on wood, plywood, MDF, or other materials.

Instead of relying on manual craftsmanship alone, the CNC router works with precision, repeatability, and speed—making it suitable for everything from cabinet doors and panel furniture to intricate wooden decorations and large-scale production.

What Factors Affect the Price?

Not every CNC wood cutting machine is the same. The cost depends on several key factors:

- Machine Size and Bed Area

- Smaller desktop machines are more affordable.

- Large-format industrial machines (for full 4×8 ft panels or bigger) cost more.

- Spindle Power

- A 3kW spindle is good for standard cutting.

- Higher power spindles (6kW–9kW) cut faster and handle thicker materials.

- Axis System

- Most entry-level machines have 3 axes (X, Y, Z).

- More advanced models add a 4th or 5th axis for 3D carving and complex cutting.

- Automation Features

- Automatic tool changers (ATC), vacuum tables, and dust collection systems increase efficiency but also raise the price.

- Brand and Service

- A trusted brand like iGoldencnc includes not only the machine but also training, technical support, and long-term spare parts service, which adds value.

Typical Price Ranges for iGoldencnc Wood Cutting Machines

From customer experiences and current market offers, here’s a general price breakdown:

- Entry-Level Models: Around $3,000 – $6,000

Suitable for small workshops, hobbyists, and custom sign-making. - Mid-Range Machines: Around $6,000 – $12,000

Ideal for furniture workshops or companies that need both speed and precision for medium-scale production. - High-End Industrial Solutions: Around $12,000 – $25,000+

Includes large-format beds, ATC systems, higher spindle power, and multi-axis capability. Perfect for factories with continuous production needs.

This wide range exists because the right machine must match your budget, material, and production target.

Why Choose iGoldencnc?

Price is important, but so is value. iGoldencnc focuses on:

- High Durability: Machines use reliable parts with long service lifespans.

- Global Service Network: Technical support and spare parts are available worldwide.

- Customization Options: Customers can choose machine configuration tailored to their production.

- Proven Experience: Thousands of installations in woodworking industries around the globe.

When you invest in a CNC router, you are not only buying a machine—you are securing years of productivity, reduced manual errors, and increased profitability.

Conclusion

So, how much does a CNC wood cutting machine from iGoldencnc cost? The short answer is: it depends on the size, spindle, automation, and features you select. Prices generally range from $3,000 for entry-level models up to $25,000+ for high-end industrial machines.

The CNC wood cutting market continues evolving, with 2025 bringing improved affordability and enhanced features across all price ranges. By understanding the price landscape and matching capabilities to your requirements, you can select a machine that provides excellent value and supports your woodworking ambitions for years to come.For a woodworking business, what matters most is not the price tag alone but the return on investment—how quickly the machine helps you boost efficiency, expand capacity, and deliver consistent quality to customers. If you are serious about upgrading, iGoldencnc provides solutions that balance cost-effectiveness with advanced performance.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.