CNC Stone Engraving Machine

The CNC stone engraving machine adopts dual independent spindles, which can carry out engraving, cutting, milling, and other processes to meet the requirements of personalized home decoration and tooling art design. The rotary saw can realize high-speed cutting of stone and improve work efficiency.

The stone CNC router is a machine tool computer-controlled and it is specially designed for all kinds of stone processing, such as marble, granite, sandstone, jade, quartz, etc. The stone CNC machine can do various processes such as carving, cutting, engraving, milling, punching, trimming, polishing, and so on. So the CNC stone router is also called: CNC stone machine, stone CNC router, CNC stone carving machine, CNC stone engraving machine, CNC stone cutting machine, tombstone engraving machine, headstone engraving machine, etc. As a stone CNC cutting machine. The stone CNC machine can meet the requirements of personalized home decoration and tooling art design. It can be used as advanced engraving processing equipment for decoration companies, handicraft industry, stone industry, the funeral industry, inscription industry, and ceramic companies. Recently, stone engraving machines have become more and more popular and welcome.

Features and A dvantages of the Stone CNC Router

- Automatic leveling function: It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

- Stable table structure: The table adopts a high-quality steel structure and double beam design. And its gantry and work surface are respectively supported by reinforced beams. Therefore, the stone carving machine has the advantages of bearing load, no deformation, and high stability.

- Super cutting ability: Adopting a high-power drive system coordinated with the spindle’s stable engraving. The stone carving machine has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive. Then, the CNC stone engraving machine has the features of strong power, high stability, and can realize the process of 70 mm Granite thickness.

- Longer service life: Use stainless steel sink, protection plate, and other parts to fully protect the transmission parts and electrical components. So that the CNC stone engraving machine has a long service life.

- Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

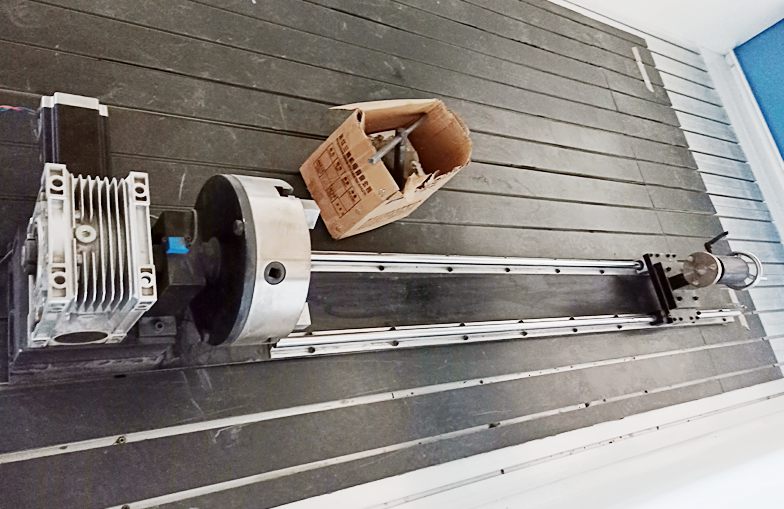

Optional rotating shaft

Optional rotating shaft, cylindrical engraving, increase the processing range and diversity.

Application of Heavy Duty Stone CNC Router with Rotary

The CNC stone engraving machine can process almost all stones, so as long as it is an industry involving stone, our CNC stone engraving machine can be used.

Stone industry: carving and processing stone, jade, marble, granite, quartz stone, artificial stone, and other stones.

Furniture industry: countertops, bar counters, floor tiles, marble cabinets, stone furniture.

Decoration industry: stone gift boxes, stone crafts, stone decorations, sculptures, 3D stone crafts, etc.

Stone tablet processing industry: stone tablet making, sarcophagus, tombstone, etc.

Advertising industry: stone advertising, artistic relief, signs, badges, etc.

Ceramic industry: all-stone ceramics, ceramic bottles, and other handicrafts.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.