Panel furniture, also known as flat-pack furniture or ready-to-assemble furniture, refers to furniture items that are manufactured and sold in a disassembled state. The furniture consists of pre-cut panels and components that can be easily assembled by the end-user using basic tools and instructions provided with the product.

Panel furniture has become increasingly popular due to its advantages. It offers affordability, as the manufacturing and transportation costs are lower compared to fully assembled furniture. It also provides flexibility, allowing customers to choose furniture that suits their style and preferences. Additionally, panel furniture is relatively easy to disassemble and move, making it convenient for people who frequently relocate or have limited space.

Panel Furniture Machines

Panel furniture machines are specialized equipment used in the manufacturing process of panel furniture. These machines are designed to automate and streamline the production of panel-based furniture items, such as cabinets, wardrobes, desks, and shelves. They help increase efficiency, precision, and productivity in the furniture manufacturing industry.

Our furniture CNC machine covers nesting CNC, edge banding machine, vacuum press machine, polishing machine, side drilling machine, six-sided drilling machine, sliding table saw, computer beam saw, hinge drill, etc. All these furniture making machines can process hardwood, softwood, MDF, particleboard, plywood and other wood materials to produce tables, chairs, kitchen cabinets, wardrobes, cupboards, shelves, beds, and other modern CNC furniture.

IGOLDENCNC provides a wide range of furniture making machines for manufacturing various modern CNC furniture. The furniture CNC equipment includes the CNC nesting machine, vacuum press machine, edge banding machine, CNC drilling machine, and auxiliary equipment. These cabinet CNC machines aim to meet the individualized and diverse processing needs of furniture production. The furniture CNC machine can be used individually or combined into a line to make CNC chair, CNC desk, and other CNC wood furniture.

What is a Panel Furniture Machine?

First and foremost, a Panel Furniture Machinery is the cornerstone of modern furniture manufacturing. It’s a state-of-the-art woodworking tool designed to streamline the production process. Therefore, these machines are built to ensure precision, efficiency, and versatility at every stage of furniture creation.

What Does a Panel Furniture Machine Include?

Our Panel Furniture Machinery comprise a comprehensive suite of essential equipment. For instance, the Edge Banding Machine enables you to craft seamless edges, elevating both the aesthetics and durability of your furniture. Similarly, the Panel & Beam Saw Machine is ideal for making accurate straight and bevel cuts on various materials, enhancing the quality of your furniture pieces. Furthermore, the Hinge Boring & Drilling Machine simplifies cabinet door and drawer assembly by drilling precise holes for hinges and handles.

What Kind of Work Can a Panel Furniture Machinery Do?

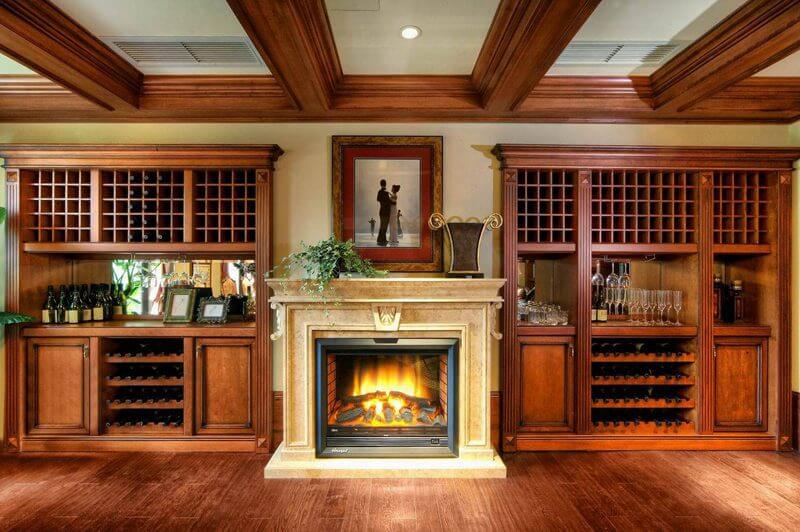

The capabilities of our Panel Furniture Machines are diverse, making them essential for various tasks. Whether you’re crafting elegant cabinets, wardrobes, and kitchen furniture with professional precision or assembling commercial fixtures and displays with uncompromising precision, these machines have you covered.

Features

Our Panel Furniture Machines are renowned for their standout features. For instance, their advanced technology ensures precision and accuracy, while streamlined processes reduce production time and labor costs. This not only gives you a competitive edge but also ensures a solid return on investment due to the machines’ durability.

Application

Our Panel Furniture Machinery find application across a spectrum of scenarios. Furniture manufacturers, aiming to optimize production processes and enhance product quality, will benefit greatly from these machines. Woodworking workshops looking to meet the demands of discerning clientele with high-quality outputs can do so with ease using these machines.

Why choose our furniture CNC machine?

Intelligent furniture CNC software can design and optimize the working path, locate work position, and carry out operations quickly and accurately. And the utilization rate of the board is increased by 40% without manual intervention.

The CNC furniture making machine has a user-friendly control interface and is easy to operate. You don’t need a long period of experience or many skills to operate. Besides, you will always learn new technical and CNC knowledge to improve your production and quality. Furniture making machine can make replicated products thousands of times.

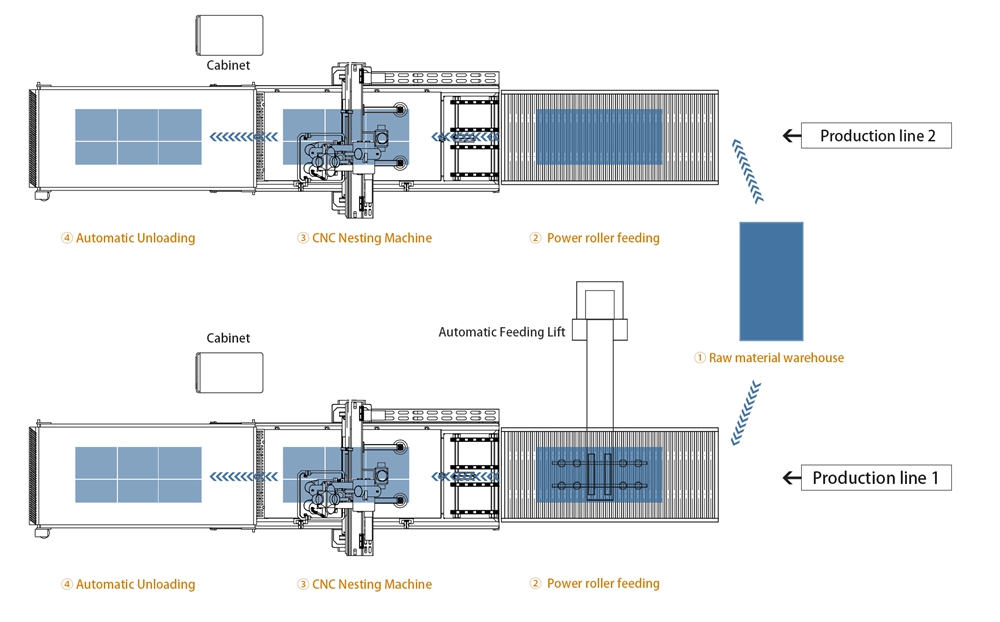

Furniture CNC machine connection lines are quite suitable for mass production with high consistency. Investing in furniture CNC machine can help you save labor costs. You can finish high-quality and precise work with few workers.

We have complete furniture CNC product ranges, and one-stop shopping can meet your diverse production needs. Automatic loading and unloading, dust removal, and positioning systems greatly improve production efficiency and reduce production costs.

CNC software allows you to stimulate your CNC table designs and other CNC furniture plans. So you don’t need to spend time and money to produce a prototype. This could save you weeks of production time when making a CNC desk or CNC chair.

How to Choose the Right Panel Furniture Machine?

Selecting the perfect Panel Furniture Machinery for your specific needs involves careful considerations. For instance, when assessing the quantity of furniture pieces you plan to produce, you need to determine the machine’s capacity. Additionally, confirming that the machine can handle the materials you intend to use, whether it’s wood, MDF, or other materials, is crucial.

Invest in our Panel Furniture Machine to transform your woodworking business. Contact us today to explore the perfect solutions tailored to your unique needs and propel your furniture production capabilities to new heights. Don’t miss the opportunity to enhance your furniture manufacturing processes with precision, efficiency, and versatility.

I am a supplier of woodworking panel furniture. I purchased IGOLDEN’s automatic production efficiency. Chinese CNC machines are affordable and high-qualitytool change woodworking machine

Hey! I simply wish to give a huge thumbs up for the good data you have got here on this post. I shall be coming back to your blog for extra soon.