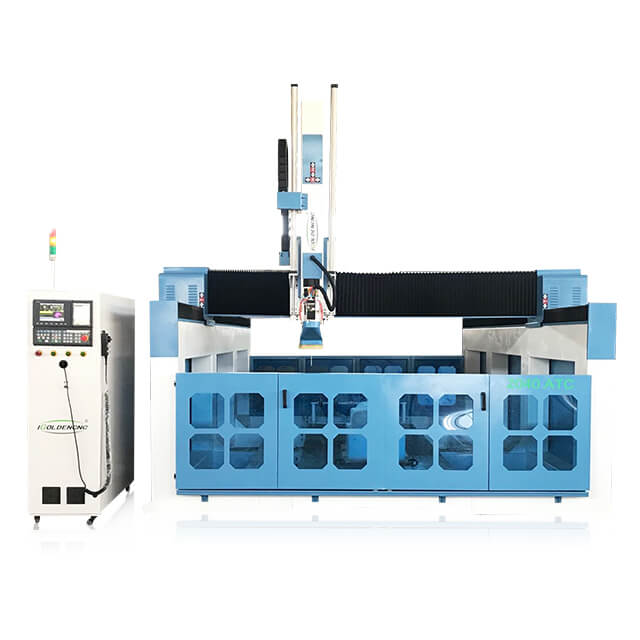

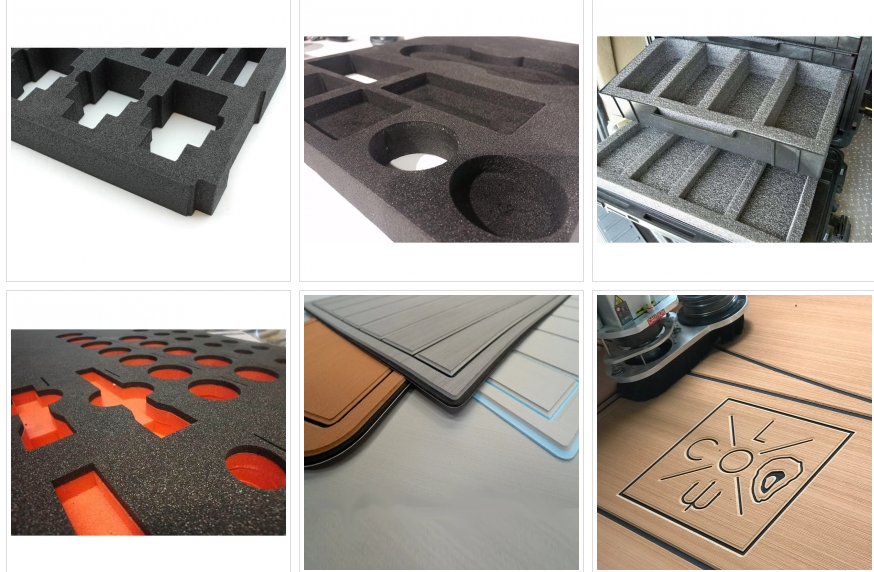

FOAM Cutting Machine with CNC Routers are widely used in foam applications, from one-off custom products to high-volume production. Our CNC routers offer both routing and knife cutting capabilities on the same machine for versatility and reliability to cut and shape virtually any type of foam.

CNC Routers are used to cut and mill non-ferrous metals including aluminum and brass effectively and efficiently. They provide an alternative to other CNC technologies such as waterjet and laser cutting that are dramatically more expensive.

CAMaster has built a versatile high-performance lineup of CNC routers for metal fabrication.

Our products provide a cost effective alternative to similar technologies for cutting aluminum, brass and other non-ferrous metals. Other methods such as waterjet and laser cutting are less practical for a lot of customers because of their limitations and price. Our routers provide a better solution at a lower cost.

By designing our routers with strong values of outstanding quality and support, we have been able to establish ourselves as a customer-driven manufacturer, providing the industry’s best CNC solutions.

We work to ensure our clients benefit from the knowledge and experience that we bring to their manufacturing process.

We Have Established Standards of Excellence

We provide flexible industry-specific solutions that have been tailor-made to simplify production while also improving the manufacturing quality.

Our products are made with performance in mind and are offered at an affordable cost. We have a proven record of customer satisfaction with thousands of machines sold. By using our industry knowledge to ensure quality products, value-driven solutions, and unsurpassed customer support, we have become a leader in the industry.

Our CNC router machines effectively work with aluminum, brass, and various other non-ferrous metals, ensuring your business will have the right tools to cut and mill effectively.

Our Products are Built to Last

CAMaster’s CNC router machines for metal fabrication are made with quality and versatility in mind. This focus on excellence represents our lifelong commitment to clients. We offer many personalized solutions to ensure customers will benefit from our industry experience.

- Standardized Methods of Production

We have a well-established production methodology that has been fine-tuned to ensure that our products are high-quality and cost-effective. Each CNC router machine is made to give our customers a competitive edge in the marketplace.

Our success has come from manufacturing with precision and agility in mind, traits that have allowed our customers to effectively take advantage of these systems.

- Client-Centered Support

CAMaster has created an extensive customer support network. From our products to our client support infrastructure, you will benefit from our top rated support as we work together to build a long-lasting relationship.

We make ourselves available to you when you need us and are committed to providing you the resources you need to achieve your goals.

- A Name You Can Trust

CAMaster has become a trusted manufacturer of CNC routers for metal fabricators because our products get results. Our manufacturing solutions outperforms the competition at much lower costs.

By leveraging our experience and knowledge, you can help your business thrive by getting a CAMaster CNC router that comes standard with a lifetime of customer support and an industry-best warranty.

We Have the Tools You Need

At CAMaster, we are dedicated to equipping our clients with the necessary tools to succeed, providing solutions that enable you to focus on being productive. Anyone from individual craftsmen to high production shops will find value in our CNC routers for metal cutting.

Take advantage of this high-quality, low-cost solution by purchasing your CNC router machine for metal fabrication from CAMaster.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.