Eps/Foam Cnc Router

Foam CNC router is also called EPS CNC wood router for processing foam. Relative to heavy-duty metal cutting machine, foam engraving machines are lightweight CNC machine. And compared with ordinary engraving machines, this type of foam engraving machine has a larger processing size and processing stroke. Especially in the mold industry such as automobile foam molds, gypsum molds, paraffin molds, large ship wooden molds, aviation wooden molds, propellers, and train wooden molds, this type EPS CNC router is very popular.

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

What Is A CNC Foam Router?

CNC foam router is referring to a dedicated routing machine for giant foam, wood or aluminum workblank milling usage. Control mode is CNC (an acronym for computer, numerical and control). It should never be an enlarged version of wood router, but rather a completely different equipment built in accordance with industrial machine tool standards from mechanical architecture to electronics. From the performance point of view, it is the same as a light duty CNC gantry milling machine.

4 Axis CNC Foam Router

The 4-axis CNC Router machine refers to the computer numerical control equipment including X, Y, Z, and additional rotation axis. It has 3 straight coordinates and 1 rotating coordinate. 4-axis CNC Router engraving machines are usually equipped with rotating axes or rocking spindles, so they can contact the workpiece from different angles and effectively work, so as to realize the 3D processing of cylindrical, curved and circular surfaces.

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

5 Axis CNC Foam Router

The 5 axis CNC Router machine, also known as the 5 axis CNC machining center, is equipped with a 3D CNC system. It is designed as a 5 axis CNC processing solution with high cost-effectiveness. It refers to the ability of the machine to move tools or parts on five different axes to achieve complex surface processing.

As advanced CNC equipment, 5 axis CNC machining center or CNC router is designed specifically for complex curved surfaces. It is widely used in aviation, aerospace, automotive, military, scientific research, precision instruments, high-precision medical equipment, and other industries. It can process an extensive range of materials, such as wood, metals, stones, plastic, styrofoam, composites, etc.

Foam CNC router is a professional CNC foam milling machine to cut and mill styrofoam (foam). It is a light CNC machine tool compared with heavy CNC metal cutting and milling machine tools, the rigidity and precision requirements of styrofoam CNC router machines are slightly lower. The CNC foam router machine is produced according to the idea of metal cutting and milling machine tools. The important processing parts of the milling machine are subjected to annealing and other heat treatment processes. After the processing is completed, three-coordinate measurement is performed to ensure the accuracy of the parts.

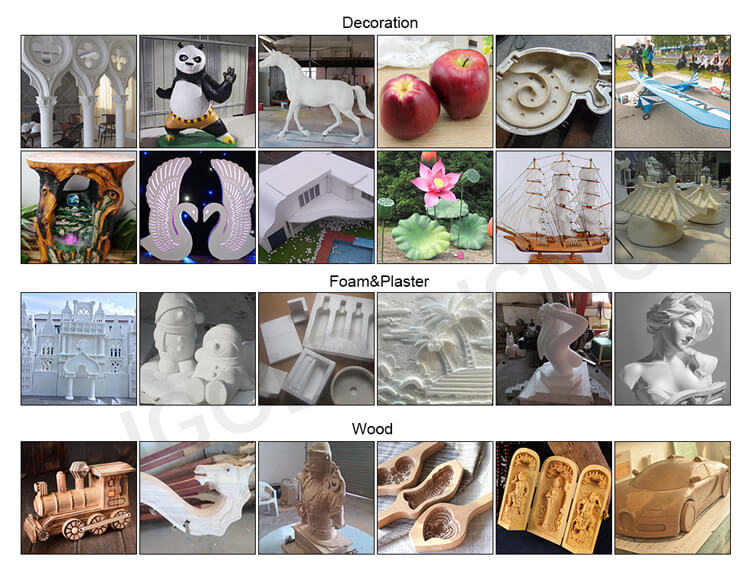

CNC Router for full automatic 2D/3D machining of carving, engraving, marking, cutting, turning, drilling, milling or grooving.Widely used in industrial manufacturing applications, Aluminum/Non-Ferrous Metal, Architectural Millwork, Education, Exhibits/Store Fixtures, Furniture, High Volume Cabinet Production, Nested Based Manufacturing, Residential/Commercial Construction, Three-Dimensional Pattern/Molds, Upholstered Frames, Advertising industry,Die industry ect.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.