In the world of woodworking, precision and accuracy are paramount. Whether you’re a professional woodworker or a passionate hobbyist, having the right tools can make all the difference in creating exquisite pieces of art. One such tool that has revolutionized the woodworking industry is the CNC wood router table. This advanced piece of machinery combines the power of computer numerical control (CNC) technology with the versatility of a router table, allowing woodworkers to unleash their creativity and achieve unparalleled precision in their projects.Whether you opt for a small, medium, or large CNC table, each size offers its own advantages and caters to different woodworking needs.

CNC Wood Router Table

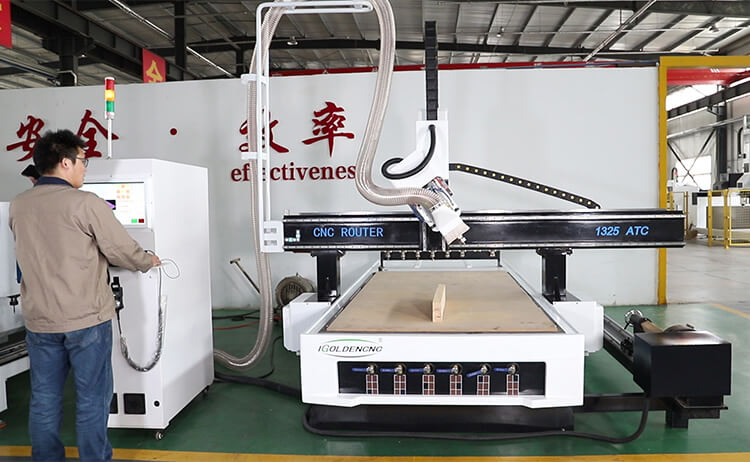

A CNC wood router table is a specialized woodworking machine that combines a router with computer-controlled movements. It consists of a flat table surface with an attached router spindle and a computer-controlled system that guides the router’s movements. This technology allows woodworkers to create intricate designs, precise cuts, and complex shapes with ease. The CNC wood router table takes woodworking to a whole new level by automating the cutting process and ensuring consistent results every time.

CNC Router Table Sizes

1. Small CNC Table

Small CNC tables are ideal for hobbyists and small-scale woodworking projects. These tables typically have a cutting area ranging from 2′ x 2′ to 2′ x 4′. They are compact, lightweight, and easy to maneuver, making them suitable for limited workspace environments. Small CNC tables are perfect for creating small signs, jewelry, and intricate carvings.

2. Medium CNC Table

Medium-sized CNC tables are a popular choice among both professionals and hobbyists. These tables offer a larger cutting area, typically ranging from 4′ x 4′ to 4′ x 8′. They provide more versatility and can accommodate larger workpieces, allowing you to take on a wider range of projects. Medium CNC tables are commonly used for furniture making, cabinetry, and architectural woodworking.

3. Large CNC Table

Large CNC tables are designed for industrial-scale woodworking operations. These tables have a cutting area that exceeds 4′ x 8′, with some models reaching up to 10′ x 20′ or even larger. They are heavy-duty machines capable of handling large and heavy workpieces. Large CNC tables are commonly used in the production of large-scale furniture, aerospace components, and architectural millwork.

CNC Router Table for Woodworking

CNC Router Machine Table for Woodworking is the perfect computer-controlled machine for cutting and engraving wood, acrylic, MDF, plastic, marble, rubber, epoxy resin, glass, foam, crystal and other materials. It typically falls into two types, ball screw-driven and rack & pinion-driven. More configuration options include carousel or linear ATC, double platforms, auto loading & unloading platforms, auto labeling platform, drilling head, etc.

Of course, if you have other machining requirements such as three-dimensional work pieces, curved surface machining of complex work pieces, we also have CNC equipment such as 4-axis CNC machine, rotary axis CNC machine, ATC CNC machine and multi-head engraving machine for you to choose.

We offers a variety of CNC for woodworking with many standard configurations for you to choose from. For instance, ATC CNC machines, 4 axis CNC machines, 3 axis CNC machines, multi-head CNC machines, mini CNC machines, best hobby CNC machines, stone CNC machines, and EPS CNC machines. In terms of worktable size, the best CNC router falls into 2×4, 4×4, 5×10, 4×8 CNC router, etc.

At its core, a wood CNC router is a computer-controlled cutting tool that uses a rotating bit to precisely carve, etch, and shape a variety of wood materials. These remarkable machines are capable of producing intricate designs, complex 3D carvings, and highly detailed elements that would be incredibly challenging, if not impossible, to achieve through traditional hand tools and manual techniques.

CNC wood router table are perfectly placed to be used in a wide range of applications and industries. Here’s a short list below:

- Cabinet making

- Custom joinery

- Kitchen fabrication

- Corian style worktops

- Campervan Conversions

- Aerospace engineering

- General fabrication

- Education

- Sign making

- Automotive engineering

- Model making

- Set and design making

- Prototyping

- Staircases

- Marine/boat manufacturing

- Personalised goods

- Exhibition stand building

What materials could you cut on a CNC wood router table?

As mentioned at the very start of this article, CNC Wood Router are extremely versatile, they give the end-user the ability to create a wide array of projects and are used in a huge number of industries. But what about the types of material you can process:

- Soft & hardwoods like pine, walnut, oak as well as MDF and plywood, OSB board etc.

- Acrylics & plastics like Plexiglass, HDPE etc

- Aluminium composites such as Dibond and Alcupanel

- Soft metals such as aluminium, brass, lead, copper

- Corian and similar acrylic-based composites

- Foam and foam board

- TRESPA

- Polystyrene

- Wood composites and veneers

- Tufnol

This list is not exhaustive, you can cut many more materials not listed.

Frequently Asked Questions (FAQ)

Q1: How does a CNC wood router table work?

A CNC wood router table works by using computer numerical control (CNC) technology to guide the movements of a router. The woodworker inputs the desired design or pattern into the computer, and the machine translates that information into precise movements of the router spindle. This allows for accurate cuts, intricate designs, and complex shapes.

Q2: Can a CNC wood router table work with different materials?

Yes, a CNC wood router table can work with various materials such as wood, plastic, and even metal. The machine’s versatility allows woodworkers to explore different mediums and expand their creative possibilities.

Q3: Is it difficult to learn how to operate a CNC wood router table?

While operating a CNC wood router table may seem intimidating at first, most machines come with user-friendly software and intuitive interfaces. With proper training and practice, woodworkers can quickly learn how to operate the machine and unleash its full potential.

Q4: Are CNC wood router tables suitable for beginners?

CNC wood router tables can be used by woodworkers of all skill levels, including beginners. While the learning curve may be steeper for beginners, the machine’s automated features and precise cutting capabilities can help beginners achieve professional-level results with ease.

The Benefits of Using a CNC Wood Router Table

1. Precision and Accuracy

One of the biggest advantages of using a CNC wood router table is the unparalleled precision and accuracy it offers. The computer-controlled system ensures that every cut, groove, and shape is executed with utmost precision, eliminating human error and producing flawless results. This level of accuracy is especially crucial when working on intricate designs or complex projects that require precise measurements.

2. Time and Effort Efficiency

With a CNC wood router table, tasks that would normally take hours or even days to complete can be done in a fraction of the time. The automated nature of the machine allows woodworkers to set up their projects, input the desired design or pattern into the computer, and let the machine do the rest. This not only saves time but also reduces physical effort, allowing woodworkers to focus on other aspects of their craft.

3. Versatility and Flexibility

A CNC wood router table offers a wide range of possibilities when it comes to woodworking. Whether you’re creating intricate carvings, precise joinery, or complex shapes, the machine can handle it all. With the ability to work on various materials such as wood, plastic, and even metal, the CNC wood router table opens up a world of creative opportunities for woodworkers.

4. Reproducibility

Consistency is key in woodworking, especially when working on multiple pieces of the same design. With a CNC wood router table, you can easily replicate the same design over and over again with absolute precision. This is particularly beneficial for woodworkers who specialize in producing furniture, cabinetry, or other items that require identical parts.

5. Enhanced Design Capabilities

The CNC wood router table allows woodworkers to explore their creativity and push the boundaries of design. With the ability to create intricate patterns, complex shapes, and custom engravings, the machine opens up a whole new world of design possibilities. Whether you’re a traditionalist or a modernist, the CNC wood router table can bring your vision to life with stunning precision.

How to choose the best CNC wood router table?

- A ridge cutter is suitable for the processing of high-density wood composite board (plywood, particleboard, hard fiberboard, blockboard, etc.) or solid wood (softwood, hardwood, and modified wood).

- A double-edged straight groove milling cutter is suitable to process the multi-layer board and plywood.

- A diamond machining tool is recommended to process the Acrylic mirror sheet.

- A multi-strip milling cutter is perfect for the processing of rough machining particleboard.

- A single-edged spiral ball-end milling cutter is suitable for processing the cork, density board, native wood, PVC board, and acrylic large-scale deep relief.

- A single-blade special aluminum milling cutter is suitable for cutting Aluminum plates.

- A round bottom cutter is recommended to process the meticulous small relief works.

- A single-edged, double-edged up and down cutting cutter is perfect for the burr-free cutting process.

- A double-tool large chip evacuation spiral milling cutter is suitable to cut the MDF board.

- A single-edged spiral milling cutter is perfect for Acrylic cutting.

Conclusion

In the world of woodworking, the CNC wood router table stands as a powerful tool that combines precision, efficiency, and creativity. With its computer-controlled movements and versatile capabilities, this machine has revolutionized the woodworking industry. Woodworkers of all skill levels can benefit from the precision and accuracy that a CNC wood router table offers. From intricate carvings to complex shapes, the possibilities are endless. Whether you’re a professional woodworker or a passionate hobbyist, investing in a CNC wood router table can take your woodworking projects to new heights. So, unleash the power of precision woodworking with a CNC wood router table and let your creativity soar.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.