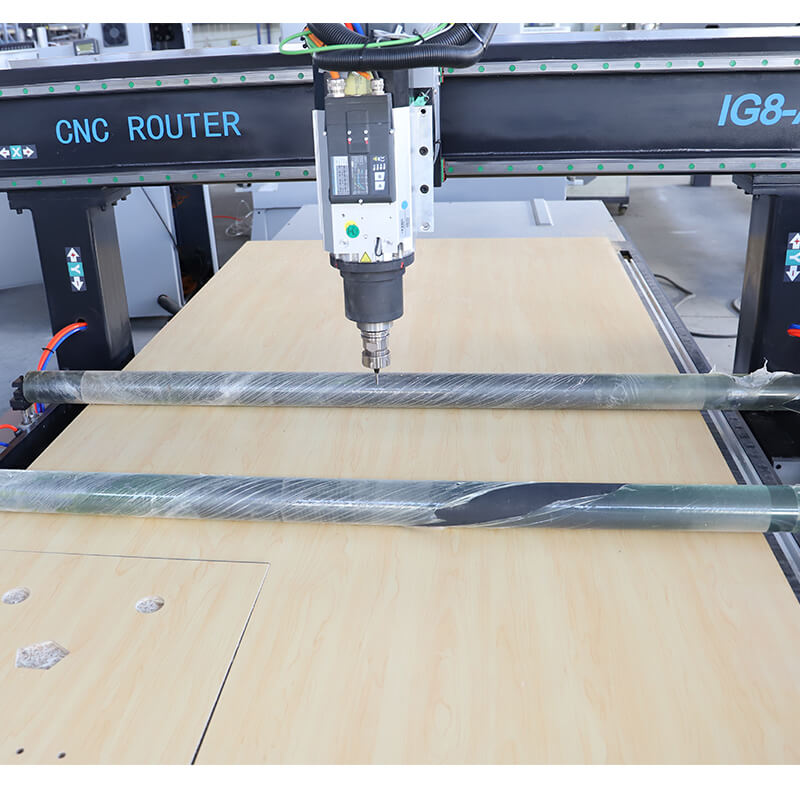

The CNC cutting machine uses professional cutting software to play its powerful functional advantages, which can be designed online, dismantled with one key, optimized plate layout, positioning, etc., improve the utilization rate of the plate, increase the saw blade device, and cut the plate more convenient; Can realize automatic loading and unloading, save labor, greatly improve the processing speed and efficiency.

It can be used with edge banding machine, laminating machine, side hole machine and other machines to customize the whole house.

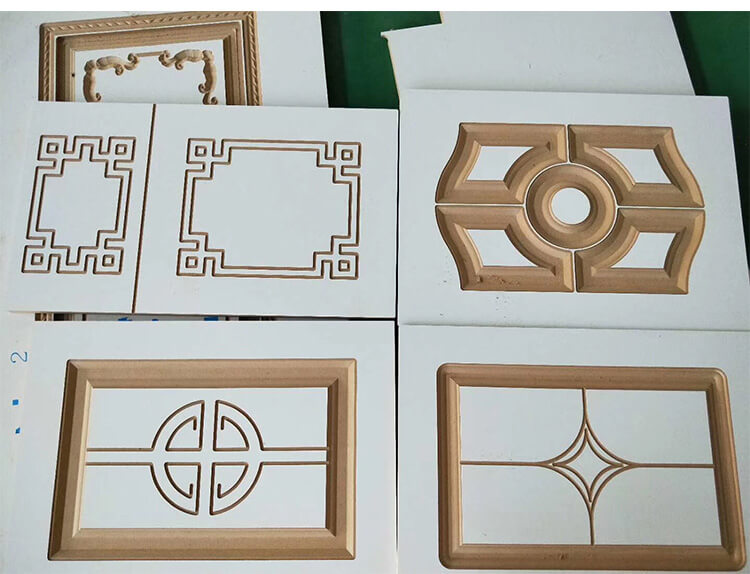

A CNC wood cutting machine is a specialized tool used in woodworking to precisely and efficiently cut, carve, or shape wood materials. CNC technology allows for highly accurate and repeatable woodworking processes, making it popular in various woodworking applications, from hobbyist projects to industrial manufacturing.

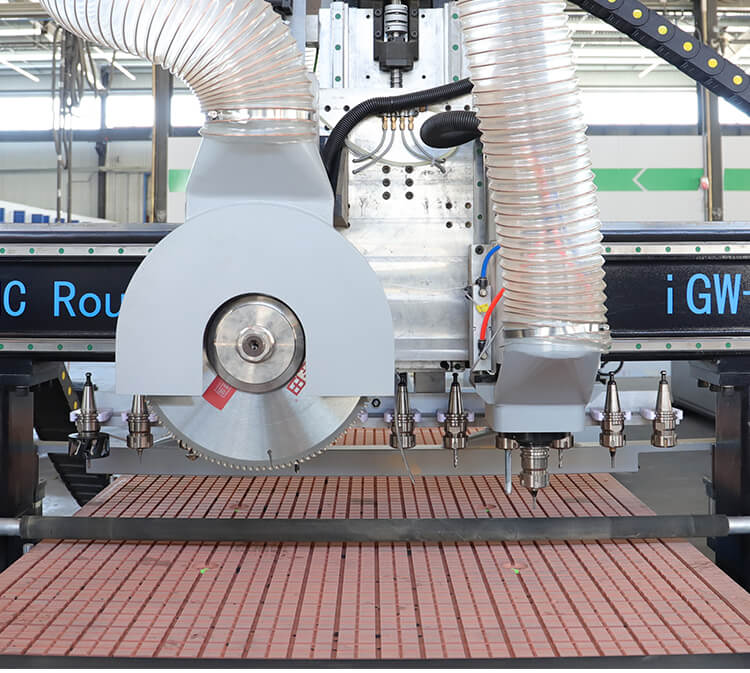

This is the newest wood cutting router machine, it supports processing a variety of materials. And the CNC wood saw cutter machine has higher machining efficiency than other machines. The CNC computer wood cutting machine is a great machine. It supports automatic loading and unloading system, so it can improve the processing range and processing efficiency of your factory. If you like this CNC wood cutter machine, then please contact us.It takes CNC machining to a new level. The floor space of this CNC wood saw cutter It has a small area and is easy to assemble and can be put into production quickly. And the CNC wood cutter machine is equipped with 9kw air-cooled spindle and cutting saw as standard, so the machining capacity of this machine is very strong. The control system of this CNC router cutting wood is Syntec bus absolute value control system, which is very professional and can perfectly realize the processing of various materials.

Nesting CNC Furniture Making Machine with Saw Features

- Adopts the design of in-line tool changing tool library, which can automatically change the tool during machining, which greatly improves the working efficiency.

- 9.0kw air cooled automatic tool change spindle and cutting saw blade, long life, reliable quality.

- IGOLDEN independent electric control cabinet, humanized design, Taiwan Baoyuan system, easy to operate.

- Using Taiwan silver guide rail and crescent rack, high positioning accuracy, smooth sliding, reliable quality, long life.

- Professional CNC Taiwan Baoyuan control system, easy to learn and easy to operate.

- Can increase the automatic loading and unloading platform, save labor costs, fast cost recovery, meet the needs of the production line, automatic intelligent operation, efficiency is greatly improved.

When considering a CNC wood cutting machine, it’s important to determine your specific needs and budget. Smaller, more affordable machines are suitable for hobbyists and small-scale woodworking projects, while larger, more expensive models are necessary for industrial woodworking and production environments. Additionally, learning how to use the associated software and machine operation is key to achieving the desired results with CNC wood cutting.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.