Six-sided drilling machine and side hole drilling machine are both common equipment in mechanical processing. Six-sided drilling machine can perform multiple processing to accurately process the hole diameter or shape on the six sides; Side hole drilling machine can process holes of different diameters through the side, which is suitable for some special processing needs. So how to choose between six-sided drilling machine and side hole machine?

What is Six-sided Drilling Machine?

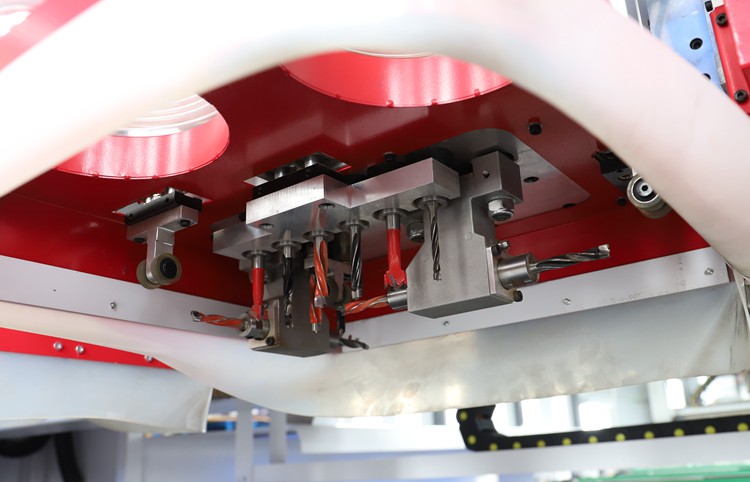

The six-sided drilling machine is a high-end CNC drilling equipment specially used for the processing of panel furniture. It adopts a beam through-type structure, automatically reads the processing information by scanning the QR code of the plate and completes the positioning, feeding and other processes, and can complete the six-sided drilling in one go. The main functions of the six-sided drilling machine include six-sided drilling, six-sided grooving, side light groove, six-sided Lamino groove invisible parts, and other diversified processing.

A Six-Side CNC Drilling Machine can drill all six sides of a panel in one cycle, including:

- Top

- Bottom

- Left

- Right

- Front

- Back

It is a highly automated CNC solution used in smart furniture production lines.

Key Features

- One-time positioning

- High automation level

- Supports complex drilling patterns

- Integrates well with nesting CNC routers

- Higher purchase and maintenance cost

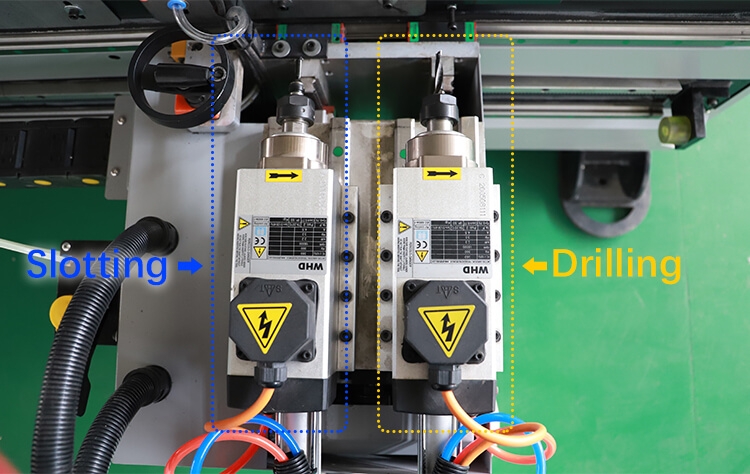

What is Side Hole Drilling Machine?

Side hole drilling machine is a kind of equipment specially used for drilling holes on the side of furniture, cabinets, doors and windows and other panel furniture to realize the assembly and connection of furniture. The working principle of the side hole drilling machine is mainly to use the main shaft rotation to drive the drill to drill holes. At the same time, the control console can adjust the drilling depth and angle of the drill to meet different furniture assembly requirements, making it an indispensable machine in the furniture manufacturing industry.

Key Features

- Focused on side holes only

- Fast drilling speed

- Simple structure and easy operation

- Low investment cost

- Ideal for batch production

Side hole machines are widely used in small and medium furniture factories because they solve one major pain point: slow and inaccurate manual edge drilling.

Core Differences at a Glance

| Item | Side Hole Drilling Machine | Six-Side CNC Drilling Machine |

|---|---|---|

| Drilling Sides | Side edges only | All six sides |

| Automation Level | Semi / automatic | Fully automatic |

| Investment Cost | Low | High |

| Operation | Simple | More complex |

| Production Scale | Small to medium | Medium to large |

| Typical Users | Cabinet factories | Smart factories |

What Are the Advantages of Six-Sided Drilling Machines and Side Hole Drilling Machines?

Advantages of Six-Sided Drilling

01 High precision

Since the six-sided drilling uses advanced digital control technology, it has advantages over the side hole machine in terms of precision and speed.

02 High efficiency

The six-sided drilling drill drills and taps at one time, while the side hole machine needs to perform drilling and tapping separately. The six-sided drilling is more efficient.

03 Multi-function

The six-sided drilling drill can perform a complete processing for different materials and sizes, while the side hole machine cannot achieve the versatility of the six-sided drilling due to its limitation on the size of the hole diameter.

04 High degree of automation

Most six-sided drilling machines are equipped with programmable controllers, which facilitates the degree of automation and production efficiency.

Advantages of Side Hole Drilling Machines

01 Suitable for large parts processing

Since the side hole drilling machine can process holes with larger diameters, it can achieve higher processing efficiency even when processing high-strength steel and other metals.

02 Low cost of use

Since the side hole drilling machine does not require a complex automatic control system, its cost is relatively low, which is very suitable for small and medium-sized enterprises or individuals.

03 Easy to maintain

The structure of the side hole drilling machine is simpler than that of the six-sided drill, and it is easier to maintain for workers familiar with mechanical maintenance.

How To Choose Between Six-Sided Drilling Machine and Side Hole Drilling Machine

When choosing between a six-sided drill and a side hole machine, the main factors to consider are production efficiency, precision, cost, and labor input.

01 Production efficiency and output

The production efficiency of a six-sided drilling machine is significantly higher than that of a side hole drilling machine. This means that if you are looking for higher production efficiency, a six-sided drilling machine is a better choice.

02 Precision of processing materials

The six-sided drilling machine completes the processing of the plate at one time, without cumulative errors, so the precision is higher. The side hole drilling machine need to be used in conjunction with the cutter, and multiple moves and flips may cause cumulative errors, thereby affecting the processing precision. If you have high requirements for the precision of the product, a six-sided driling machine is a better choice.

03 Cost and labor input

The price of a six-sided drilling machine is usually higher than that of a side hole machine, but in the long run, the six-sided drilling machine has a higher return on investment due to improved production efficiency and labor cost savings. Although the initial investment cost of a six-sided drilling machine is high, it can reduce the number of manual flips and picks, thereby saving a lot of labor costs. Therefore, if your production volume is large and your budget is sufficient, the six-sided drilling machine is a better choice.

04 User group needs

Side hole drilling machines are suitable for some specific production needs, such as the production of invisible parts and cabinets with mortise and tenon processes, etc. Side hole drilling machines may have more advantages in these application scenarios. If your product is mainly aimed at these specific needs, the side hole drilling machine may be a more suitable choice .

Cost and ROI Analysis

Cost is often the biggest deciding factor.

- Lower purchase cost

- Lower maintenance cost

- Short payback period

- Ideal for factories upgrading from manual drilling

- High initial investment

- Higher requirements for power, space, and operators

- Better ROI only at large production volumes

For many factories, starting with a side hole drilling machine is a safer and more flexible investment.

Conclusion

In summary, whether to choose a six-sided drilling machine or a side hole drilling machine needs to be determined based on your specific production needs, budget, production efficiency requirements, and product accuracy requirements. If you have a large production volume, high requirements for accuracy, sufficient budget, and pursue high efficiency, then the six-sided drilling machine is a better choice. If your production needs are mainly concentrated on specific processes and your budget is limited, then the side hole drilling machine may be more suitable for you.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.