The 5 axis CNC mill is equipped with a 5-axis head, and plus a 9kw automatic tool change air cooling spindle, which makes the machine more powerful. Syntec CNC controller Taiwan of 5 axis foam CNC has high-speed precision, which greatly improves the production efficiency of 5 axis router.The 5 axis router is suitable for processing foam, 3D molds, other materials.

5 Axis CNC Milling Machine For 3D Modeling & Cutting

5 axis CNC milling machine with double tables is designed for 3D cutting, 3D mold making, and 3D modeling, such as wood mold making, foam mold making, automotive models, metal mold making, building models.This upgraded 5 axis CNC machining center is added with a protective cover, carousel ATC magazine and T slot & vacuum table. which can realize more complex and precise parts processing, and improve production efficiency and product quality.

5 Axis CNC Mill Router Features

- The T slot & vacuum table with 2 zones has stronger adsorption capacity and is easier to fix the material.

- The metal sheet cover on the Z axis is both beautiful and dustproof.

- 12-tool carousel magazine can automatically change tools to realize more complex works.

- The 12kw water cooling spindle can rotate 360° for fast 3d engraving.

- All accessories are from international first-line brands, ensuring the processing accuracy and quality.

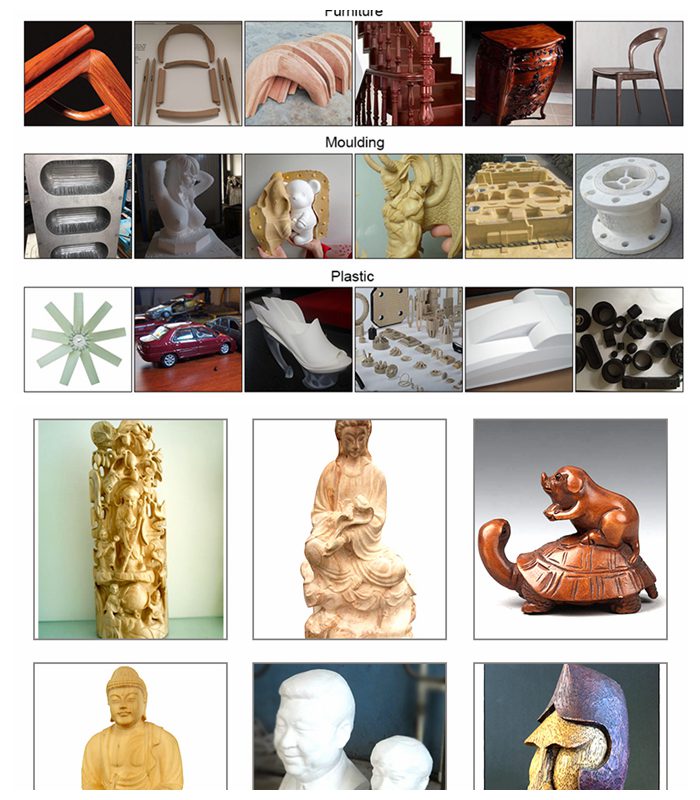

What Are 5 Axis CNC Routers Used For?

The 5 axis CNC router is designed to deliver high speed and quality cuts for a wide range of materials. These include but are not limited to wood, plastics, non ferrous metals and other composites. The 5 axis CNC router provides various new applications including:

1. Edge Trimming Of Thermoformed Plastic, Molded Plastic And Composite Parts The flexibility of the 5 axis machine creates the ability to provide high quality finishing and edge trimming on many manufactured plastic items.

2. Deep Cavity Mold Making On three axes machines deep cavity mold making requires that you have longer tools to be able to reach deep enough. Having longer tools results in the user having to reduce cutting speed to prevent breakage. With the added movement provide by 5 axis machining, shorter tools can be used, and your cutting speed can be increased.

3. Molded Plywood Chairs And Decorative Furniture Parts The 5 axis CNC router allows for unique shaping and molding of various materials, allowing you to make your creative and dynamic designs a reality.

4. Detailed 3D Carvings The increase in movement of the cutting tool on the 5 axis CNC router allows it to carve intricate designs into a piece of material. It allows you to capture the fine details of your design in the job you are cutting.

A 5-axis CNC milling machine is a computer-controlled milling machine that can perform machining operations along five different axes simultaneously. Unlike traditional 3-axis milling machines that can move along the X, Y, and Z axes, a 5-axis machine adds two additional axes of rotation, typically referred to as the A and B axes. This additional flexibility allows for more complex and precise machining operations.5-axis CNC milling machines excel at machining complex geometries and contours, such as sculpted surfaces, freeform shapes, and intricate details. They can produce parts with complex features that would be challenging or impossible to achieve with traditional 3-axis machines.

The simultaneous multi-axis machining and reduced setup times offered by a 5-axis machine contribute to improved efficiency and productivity. It eliminates the need for manual repositioning and multiple machine setups, allowing for faster and more streamlined production processes.

The multi-axis capabilities of a 5-axis machine enable it to maintain consistent tool contact with the workpiece, resulting in improved surface finish. It reduces tool marks and allows for smoother, more refined surfaces on the machined parts.

With a 5-axis machine, complex parts can often be machined in a single setup, reducing the time required for tool changes and repositioning. This leads to shorter setup times and increased productivity.

The ability to tilt and rotate the workpiece and cutting tool allows for improved accuracy and precision in machining. It reduces the need for multiple setups and adjustments, resulting in higher-quality finished parts with tight tolerances.

The additional axes of rotation provide increased flexibility in positioning the workpiece and accessing various angles and surfaces. This makes the 5-axis CNC milling machine suitable for machining complex parts, molds, dies, aerospace components, and sculptures.

5-axis machine can move the cutting tool along five axes simultaneously, enabling it to approach the workpiece from multiple angles. This capability allows for the machining of complex shapes, contours, undercuts, and intricate features in a single setup.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.