4-axis linkage CNC router is a computer numerical control (CNC) machine that utilizes four axes of motion to perform cutting, carving, and milling operations on various materials. Unlike a 3-axis CNC router that can move in the X, Y, and Z directions, a 4-axis machine adds an additional rotational axis, typically referred to as the A-axis or rotary axis.

4 Axis Linkage CNC Router

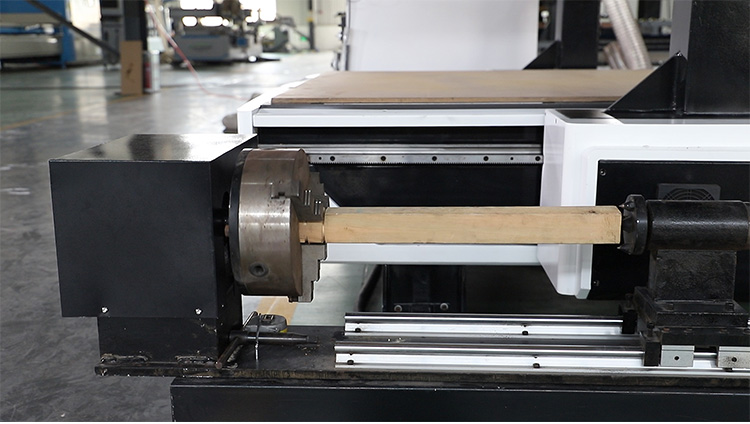

This CNC wood router for sale is a multifunctional machine,this machine contains ATC Function.So it can be used in making cabinet furniture.The wood door making CNC router machine also come standard with horizontal spindle and rotary spindle.The horizontal spindle can be used for drilling and milling the keyhole and hinge for door making. The rotary axis can be used for making furniture legs, such as chair legs, table legs, sofa legs, and many other three-dimensional products.

The A-axis provides the flexibility to machine complex shapes, contours, and irregular surfaces that cannot be achieved with a 3-axis system alone. It is commonly used in applications such as rotary carving, 3D relief carving on cylindrical objects, engraving on curved surfaces, and machining of columns, posts, and furniture legs.

The A-axis provides rotational movement to the cutting tool, enabling it to tilt or rotate around the X, Y, or Z axis. This rotational capability allows the router to perform tasks such as carving intricate designs on cylindrical or curved surfaces, creating tapered cuts, and producing 3D contours with smoother transitions.

4-axis CNC routers can often complete tasks more efficiently compared to manual woodworking methods or 3-axis CNC machines. The ability to perform multiple operations in a single setup reduces production time and minimizes material waste, leading to improved productivity and cost-effectiveness.

4-axis wood CNC router come in various sizes and configurations to accommodate different workspace requirements and production needs. Some machines are tabletop models suitable for small-scale projects, while others are larger industrial-grade machines capable of handling larger workpieces and higher production volumes.

Here’s an overview of the four axes commonly found in a 4-axis linkage CNC router:

- X-axis: The X-axis represents the horizontal movement of the machine’s cutting head or spindle.

- Y-axis: The Y-axis represents the vertical movement of the cutting head.

- Z-axis: The Z-axis represents the depth or height movement of the cutting head.

- A-axis (Rotary axis): The A-axis is the additional rotational axis in a 4-axis CNC router.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.