3 Axis Stone CNC Router

A 3-axis stone CNC router is a computer numerical control (CNC) machine specifically designed for cutting, carving, and engraving stone materials. It utilizes three linear axes (X, Y, and Z) to move the cutting tool or spindle in different directions to create precise and intricate designs on stone surfaces.

The stone CNC router is provided with a heavy-duty structure to carve and engrave various types of stone, crystal, wood, jade, artificial, and synthetic materials. Its major functions include embossing, lettering, hollowing out, cutting, seamless stitching, milling, grinding, etc. So it has wide applications in garden engineering, inscription, stone sculpture, craft, and artwork industries.

3 axis stone CNC router is a valuable tool for stone fabricators, sculptors, and other professionals working with stone materials. It enables the creation of complex designs and detailed engravings with efficiency and accuracy, expanding the possibilities for artistic expression and craftsmanship in the stone industry.

Advantages of the Stone CNC Router

- Automatic leveling function: It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

- Stable table structure: The table adopts a high-quality steel structure and double beam design. And its gantry and work surface are respectively supported by reinforced beams. Therefore, the stone carving machine has the advantages of bearing load, no deformation, and high stability.

- Super cutting ability: Adopting a high-power drive system coordinated with the spindle’s stable engraving. The stone carving machine has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive. Then, the CNC stone engraving machine has the features of strong power, high stability, and can realize the process of 70 mm Granite thickness.

- Longer service life: Use stainless steel sink, protection plate, and other parts to fully protect the transmission parts and electrical components. So that the CNC stone engraving machine has a long service life.

- Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

Key Features of 3 Axis Stone CNC Router

- Cutting and Carving Capability: The machine is capable of cutting and carving stone materials such as marble, granite, limestone, and other natural or engineered stones. It can create various shapes, patterns, reliefs, and even 3D sculptures on stone surfaces.

- Three Linear Axes: The X, Y, and Z axes provide movement in three directions. The X-axis moves the cutting tool horizontally from left to right, the Y-axis moves it forward and backward, and the Z-axis moves it up and down. This combination of movements allows for precise control and positioning of the cutting tool on the stone surface.

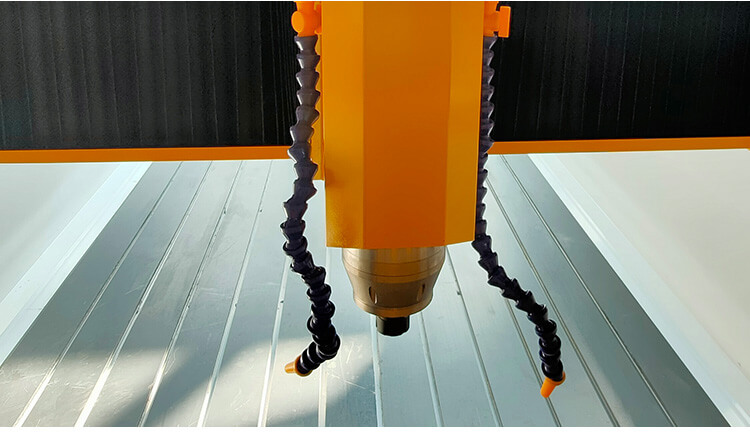

- Spindle and Cutting Tools: The machine is equipped with a high-speed spindle that rotates the cutting tool. Different types of cutting tools, such as diamond-tipped bits or milling cutters, can be used depending on the desired cutting or carving application.

- Precision and Accuracy: A 3-axis stone CNC router offers high precision and accuracy, ensuring that intricate designs or details are replicated with consistency. The machine can achieve fine lines, sharp edges, and smooth surfaces on stone materials, resulting in high-quality finished products.

- CAD/CAM Software: The machine is operated using computer-aided design (CAD) and computer-aided manufacturing (CAM) software. Users can create or import design files, specify tool paths, and control cutting parameters through the software interface. The software also allows for simulation and preview of the cutting process before execution.

- Dust Collection System: Stone cutting and carving can generate a significant amount of dust. Many 3-axis stone CNC routers are equipped with dust collection systems that help remove and control dust during the cutting process, ensuring a cleaner working environment.

- Worktable and Fixturing: The machine typically has a sturdy worktable that holds the stone material securely in place during cutting or carving. Various fixturing methods, such as clamps or vacuum systems, are used to ensure stability and accuracy during the machining process.

CNC Stone Engraving Machine Applications

The CNC Stone carving machine can process almost all stones, so as long as it is an industry involving stone, Our CNC Stone carving machine can be used. Next, I will introduce to you the application industry of CNC Stone carving machines.

Stone industry: carving and processing stone, jade, marble, granite, quartz, artificial stone, and other stones.

Furniture industry: countertop, bartop, floor tiles, marble cabinets, stone furniture.

Decoration industry: stone gift boxes, stone crafts, stone decorations, sculptures, 3D stone crafts, etc.

Stone tablet processing industry: stone tablet making, sarcophagus, tombstone, etc.

Advertising industry: stone advertising, artistic relief, signs, badges, etc.

Ceramic industry: all stone ceramics, ceramic bottles, and other handicrafts.

Applicable materials: marble, granite, quartz, jade, bluestone, black stone, etc., as well as non-stone materials such as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo, and wood. Hardstone such as granite can be carved in layers to 5mm

Marble, bluestone, etc. can be carved up to 5mm at a time.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.