In the realm of woodworking, the art of engraving has long been a cherished tradition, where skilled artisans meticulously carve intricate designs and patterns into the natural beauty of wood. However, as technology continues to evolve, a new player has emerged in the field of woodworking engraving – the CNC (Computer Numerical Control) machine. As woodworkers and craftspeople navigate this dynamic landscape, it’s essential to understand the unique advantages and considerations of both CNC engraving and traditional hand engraving techniques.

Woodworking Engraving CNC Machines: Precision and Efficiency

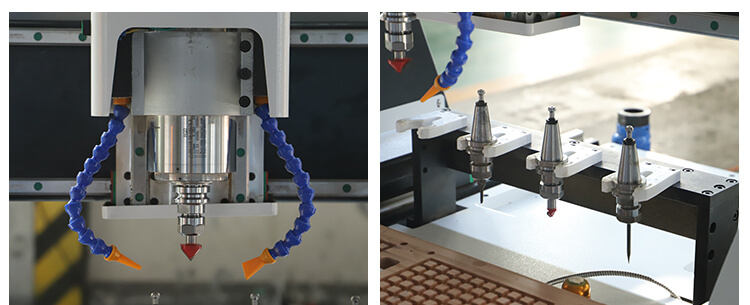

CNC engraving machines have revolutionized the woodworking industry, offering a level of precision and efficiency that was once unimaginable. These computer-controlled machines are programmed to execute complex engraving designs with remarkable accuracy, consistency, and speed.

- Unparalleled Precision: CNC engraving machines can reproduce intricate, detailed designs with a level of precision that is virtually impossible to achieve through manual hand engraving. The use of computer-controlled cutting tools and advanced software ensures that every element of the design is executed with meticulous attention to detail.

- Increased Productivity: CNC engraving machines are capable of operating at high speeds, significantly reducing the time and labor required to complete complex engraving projects. This increased efficiency allows woodworkers to take on more projects, meet tighter deadlines, and improve their overall profitability.

- Consistent Replication: Once a design is programmed into the CNC machine, it can be replicated with perfect consistency, ensuring that every finished piece is identical in quality and appearance. This is particularly beneficial for mass-produced or custom-ordered items.

- Expanded Design Possibilities: The integration of CAD (Computer-Aided Design) software with CNC engraving machines opens up a world of creative possibilities. Woodworkers can now explore and execute intricate, highly detailed designs that would be virtually impossible to achieve through manual engraving methods.

Hand Engraving: The Art of Craftsmanship

While the advantages of CNC engraving machines are undeniable, the art of hand engraving continues to hold a special place in the hearts of many woodworkers and craft enthusiasts. This traditional approach to engraving offers a unique set of benefits.

- Personalized Touch: Hand engraving allows woodworkers to infuse each piece with their own personal touch and artistic expression. The subtle variations and imperfections inherent in hand-carved designs can lend a one-of-a-kind, artisanal quality to the finished product.

- Emotional Connection: The process of hand engraving can be a deeply rewarding and meditative experience, fostering a strong emotional connection between the woodworker and the final piece. This connection can be particularly valuable for custom, bespoke items or when creating personal, sentimental pieces.

- Versatility in Materials: Hand engraving techniques can be applied to a wider range of materials, including delicate or irregularly shaped woods, that may be more challenging to process with a CNC machine.

- Preservation of Tradition: For many woodworkers, hand engraving represents a time-honored tradition that connects them to the rich history and heritage of their craft. Preserving this artisanal approach can be a source of pride and a means of passing down essential skills to future generations.

Woodworking engraving machine VS hand engraving

1. Different carving effects

The relief production of woodworking engraving machine is designed by the engraving software to design the engraving path and then input into the computer for automatic engraving. Therefore, the details of the engraving are neat and unified. Whether it is a flower plate or a cloud bead, every place is the same size, and it looks like nothing different. This is extremely suitable for mass production, making furniture manufacturing more refined and perfect. Hand-engraving can’t be compared with a woodworking engraving machine regardless of its accuracy. However, hand-engraving also has its own unique advantages. It can “pierce through the branches” to carry out multiple layers of openwork, making the carved workpiece look full of life.

2. Different engraving efficiency

Compared with hand-carving, woodworking engraving machine embossing production has fast engraving efficiency and engraving accuracy, which is far from being comparable to hand-carving. Some customers also choose a woodworking engraving machine to engrave and then do the manual modification, which can make the engraving efficiency and precision higher.

3. Different carving details

Compared with hand-carving, woodworking engraving machine embossing has the same depth, and the transition point is smoother. When hand-carving, the carving depth is different and the carving depth is limited.

4. Possible development trends of the carving industry

What will the final development trend of woodworking engraving machine embossing and hand-carving be like?

It is undeniable that the embossing production of woodworking engraving machine will make the mahogany furniture market trend, and also prompt the mahogany furniture industry to adapt and survive quickly. The classification of mahogany furniture has been replaced by the exquisite CNC woodworking engraving machine furniture carving, which continues to occupy the high-end market. What can survive the tide of embossing on woodworking engraving machines must be hand-carved boutiques. From styles to workmanship, it embodies unsurpassed manual craftsmanship like top luxury goods, occupying the highest-end market of mahogany furniture. To be loved by experts and collectors.

In the mass production of woodworking engraving machines, in the factory’s production line mode, each piece is mass-produced according to a fixed template to make the appearance of the product more coordinated.

- The overall steel structure of the machine bed is welded and subjected to vibration aging treatment to ensure that it will not be deformed in use.

- Reliable controller system: German Siemens controller/Syntec controller/DSP controller/Mach3 control system.

- The original imported ball screw is used for smooth operation. The X and Y axis adopt high-precision synchronous belts and wheel transmission to ensure the high precision of the machine.

- Using high-precision rack and pinion transmission and imported square linear guide, fast speed, and high precision.

Conclusion

Ultimately, the choice between woodworking engraving CNC machines and hand engraving depends on the specific requirements of the project and the desired outcome. CNC machines are well-suited for precision, efficiency, and complex designs, while hand engraving offers a personal touch, artistic flair, and a connection to traditional craftsmanship.

Whether you opt for the precision of a CNC machine or the artistry of hand engraving, both methods have their own merits and can produce beautiful and intricate engravings on wood surfaces. If you have any further questions or need assistance in making a decision, feel free to ask for more guidance in your woodworking endeavors!

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.