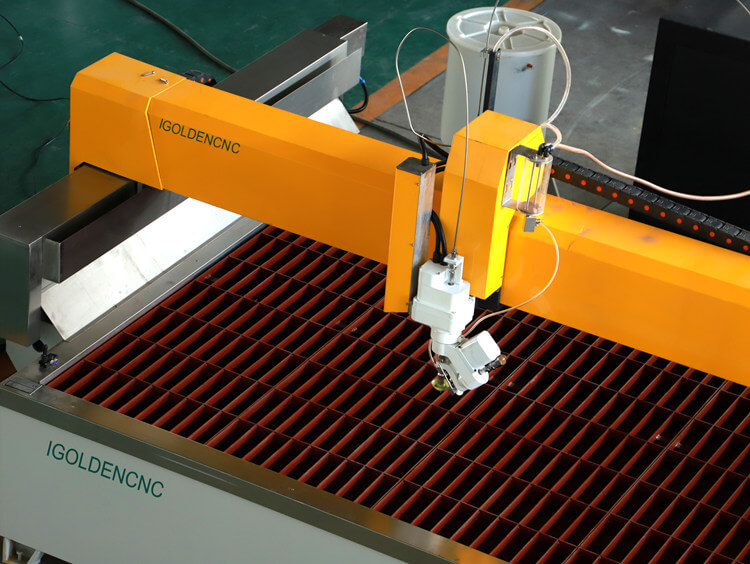

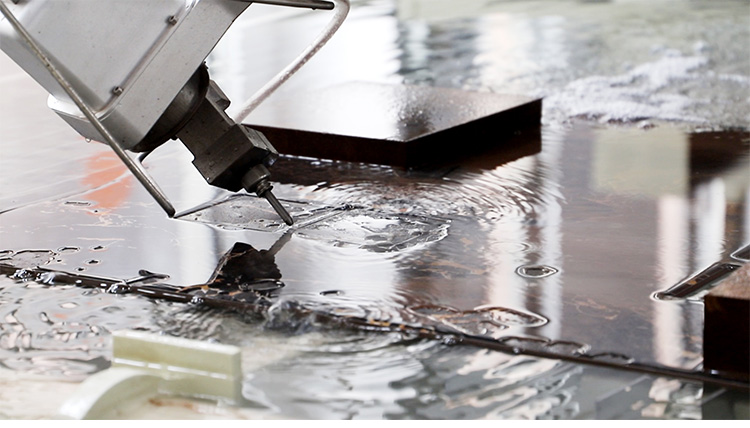

CNC water jet cutting stands as one of the most versatile material processing technologies available in modern manufacturing. Unlike thermal cutting methods that use heat, waterjet systems cut materials using an ultra-high-pressure stream of water, often mixed with abrasive particles, traveling at speeds exceeding twice the speed of sound. This cold-cutting process enables waterjet machines to cut virtually any material without causing heat-affected zones, material distortion, or hazardous fumes.

Suitable Materials for CNC Water Jet Cutting Machine

The CNC Water Jet Cutting Machine is engineered to cut a wide range of materials with high precision and versatility. It can efficiently handle hard and dense materials, providing clean and accurate cuts without heat distortion. Below are the suitable materials for this water jet cutting machine:

Ferrous Metals

Steel and Mild Steel – Waterjet excels at cutting steel in thicknesses from thin gauge sheet metal to plates exceeding 150mm. The cold-cutting process preserves material properties without creating hardened edges or thermal distortion. Steel fabricators appreciate waterjet’s ability to cut complex shapes with tight nesting to minimize material waste.

Stainless Steel – All grades of stainless steel cut cleanly with waterjet technology. The absence of heat prevents oxidation and discoloration that plague laser and plasma cutting. Medical device manufacturers and food processing equipment fabricators rely on waterjet for contamination-free stainless steel cutting that maintains corrosion resistance.

Tool Steel and Hardened Steel – Waterjet cuts pre-hardened tool steels and heat-treated components that would damage or wear out conventional cutting tools rapidly. Manufacturers can cut finished hardened parts without annealing, saving significant time and cost in tool and die production.

Cast Iron – Despite its brittleness, cast iron cuts successfully with properly tuned waterjet parameters. Slower cutting speeds and optimized abrasive flow prevent cracking while producing clean edges on machinery components and industrial castings.

Non-Ferrous Metals

Aluminum and Aluminum Alloys – Waterjet cutting handles all aluminum grades from soft pure aluminum to aerospace-grade alloys like 7075-T6. The cold process eliminates melted edges and dross formation common with thermal cutting. Aircraft manufacturers use waterjet extensively for aluminum structural components and skin panels.

Copper and Brass – These highly reflective and thermally conductive metals pose challenges for laser cutting but waterjet processes them effortlessly. Electrical component manufacturers cut copper bus bars, contacts, and heat sinks with precision. Brass decorative items and plumbing components benefit from waterjet’s clean edges requiring minimal finishing.

Titanium – Aerospace and medical industries depend on waterjet for cutting expensive titanium materials. The cold cutting prevents work hardening and maintains the material’s unique properties. Waterjet cuts titanium at reasonable speeds while producing burr-free edges critical for aircraft components and medical implants.

Exotic Alloys – Inconel, Hastelloy, Monel, and other exotic nickel alloys machine with extreme difficulty but waterjet cuts them efficiently. These specialty materials serve in chemical processing, nuclear applications, and high-temperature environments where waterjet’s cold cutting prevents microstructural changes.

Stone and Minerals

Granite – Natural granite slabs cut precisely for countertops, monuments, and architectural features. Waterjet creates intricate designs, curved edges, and sink cutouts without cracking or chipping the brittle stone. The technology enables complex inlay work and decorative patterns impossible with traditional stone cutting methods.

Marble – Delicate marble benefits from waterjet’s gentle cutting action that preserves the stone’s natural beauty without causing fractures. Waterjet cuts thin marble tiles and thick slabs equally well, making it ideal for flooring, wall cladding, and decorative installations.

Quartz and Engineered Stone – Engineered quartz countertops require clean cuts through extremely hard, abrasive material. Waterjet handles these composites efficiently while maintaining sharp edges and corners critical for professional countertop fabrication.

Tile and Ceramics – Porcelain tiles, ceramic tiles, and glass tiles cut precisely for custom borders, medallions, and artistic installations. Waterjet enables curved cuts and intricate patterns that expand design possibilities beyond standard rectangular tiles.

Concrete and Cement Board – Waterjet cuts concrete, fiber cement board, and concrete pavers for construction applications. The process creates clean edges without generating excessive dust or requiring grinding.

Composites and Advanced Materials

Carbon Fiber – Aerospace and automotive applications demand precise carbon fiber cutting without delamination. Waterjet’s cold cutting preserves the fiber-resin bond while producing clean edges. The process eliminates dust and respiratory hazards associated with mechanical cutting of carbon composites.

Fiberglass (FRP) – Boat builders and industrial equipment manufacturers use waterjet to cut fiberglass components. The technology prevents delamination, fiber fraying, and dangerous dust generation while maintaining dimensional accuracy.

Kevlar and Aramid Fibers – These tough materials resist conventional cutting tools but waterjet processes them cleanly. Body armor manufacturers and industrial applications benefit from precise Kevlar cutting without heat damage.

Honeycomb Core Materials – Aluminum and aramid honeycomb structures used in aerospace sandwich panels cut cleanly without crushing cells. Waterjet maintains the structural integrity essential for lightweight aerospace components.

Plastics and Polymers

Acrylic (PMMA) – Clear acrylic sheets cut with optically clear edges requiring no polishing for many applications. Sign makers and display manufacturers produce complex shapes and fine details impossible with traditional methods.

Polycarbonate – This tough, impact-resistant plastic cuts without melting or deforming. Machine guards, bullet-resistant panels, and aerospace windows benefit from waterjet’s precision cutting.

ABS and PVC – Common industrial plastics cut efficiently for prototype development and production parts. The cold process prevents melting and toxic fume generation associated with thermal cutting.

Nylon and UHMW – These wear-resistant plastics machine with difficulty but waterjet cuts them cleanly. Conveyor components, wear strips, and industrial parts benefit from waterjet processing.

Rubber and Elastomers – Pure waterjet (without abrasive) cuts rubber, foam rubber, gasket materials, and silicone precisely. Automotive gasket manufacturers and seal producers depend on waterjet for high-volume production.

Glass and Optical Materials

Tempered Glass – Waterjet cuts tempered glass before the tempering process, enabling complex shapes in safety glass applications. Automotive windshields and architectural glass benefit from precise cutting capabilities.

Laminated Glass – Multiple glass layers with polymer interlayers cut cleanly without delamination. Bullet-resistant glass and safety glazing applications utilize waterjet technology.

Optical Glass – Precision optical components cut from specialty glass materials maintain surface quality and dimensional accuracy. Waterjet enables cost-effective production of complex optical geometries.

Glass Tile and Mosaics – Decorative glass tiles cut precisely for artistic installations and architectural features. Waterjet creates intricate patterns and custom shapes for high-end design projects.

Wood and Natural Materials

Hardwood and Softwood – Waterjet cuts intricate wooden components for furniture, musical instruments, and decorative items. The process produces smooth edges without burning or splintering.

Plywood and MDF – Engineered wood products cut cleanly for cabinetry, furniture, and architectural elements. Waterjet prevents delamination and edge damage common with saw cutting.

Cork and Bamboo – Sustainable materials cut precisely for flooring, wall coverings, and specialty products. Waterjet maintains the natural appearance while enabling creative designs.

Food Products

Pure waterjet cutting serves the food processing industry for cutting products including frozen meat, fresh produce, baked goods, candy, and cheese. The process maintains food safety standards, produces no contamination, and enables portion control with exceptional accuracy.

Application of CNC Water Jet Cutting Machine

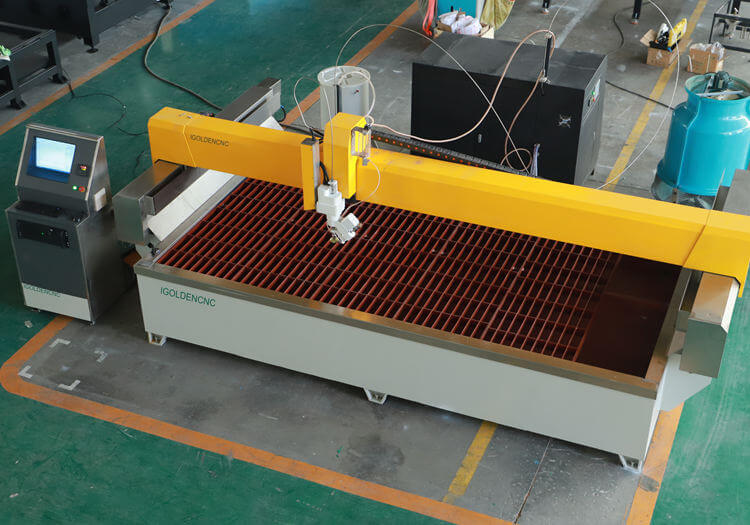

The CNC Water Jet Cutting Machine for Marble, Steel, Granite, and Stone Cutting is designed to meet the demands of a wide range of industries that require precision cutting of various hard materials. The machine’s rotary feature enhances its versatility, enabling it to efficiently handle complex and intricate designs across multiple applications.

Key Applications:

-

Marble and Granite Cutting

-

Ideal for creating intricate patterns and designs in marble and granite for use in countertops, flooring, and decorative surfaces.

-

The high-pressure water jet ensures clean and precise cuts without causing material distortion or heat damage.

-

-

Stone Sculpting

-

Perfect for artists and manufacturers in the stone industry, offering the ability to cut through thick and dense stones with high precision.

-

Rotary capabilities enable the creation of 3D sculptures and detailed carvings.

-

-

Steel and Metal Cutting

-

Suitable for cutting steel and other metals used in construction, automotive, and manufacturing industries.

-

The CNC water jet cutting process is perfect for making clean, precise cuts without heat-affected zones.

-

-

Architectural and Interior Design

-

Used in the creation of customized architectural elements such as decorative stone panels, metal fixtures, and stone carvings for interior and exterior design.

-

Rotary cutting allows for the production of circular patterns and rounded edges.

-

-

Aerospace and Automotive Industries

-

Enables the precise cutting of complex parts for the aerospace and automotive industries, particularly in the fabrication of components that require intricate detailing.

-

Capable of cutting hard materials like steel and aluminum, ideal for creating structural parts and intricate designs.

-

-

Custom Signage and Artwork

-

The rotary function is perfect for cutting custom logos, letters, and other designs for signage made from materials like stone, granite, or metal.

-

Allows for fine detail work and the creation of unique, custom-made signs.

-

-

Prototype and Model Making

-

Essential for creating prototypes and models in industries such as architecture, engineering, and product development.

-

Precision cutting enables the creation of detailed models from various materials including stone, metal, and composites.

-

The CNC Water Jet Cutting Machine for Marble, Steel, Granite, and Stone Cutting with rotary capability is a versatile tool for industries that demand high precision and flexibility, offering high-quality results across diverse applications.

Getting the Right Water Jet For Your Stone Cutting Needs

Choosing the right water jet cutting equipment can be challenging, as it is a vast market. Many manufacturers throw out a lot of technical terms to try and make their products appear the best.

However, deciding on the most suitable waterjet cutting machine should depend on your particular requirements. Here are some of the factors you should consider:

Budget

Outline a budget to spend on a water jet cutter. More features come at a higher price, so factoring in your budget can help you choose the equipment you can afford and features to ignore.

Water Pressure

The water pressure of the water jet cutting machine will have a significant impact on the price. A medium-pressure pump will suffice if you want to cut stones of moderate thickness. You will require a more versatile ultra-high-pressure machine to handle the thickest materials.

Cutting Axes

A higher number of cutting axes on a waterjet cutting machine allows you to handle cutting shapes of greater complexity. A 5-axis cutter can create any intricate designs you require.

Added Features

Some users might seek specific features for waterjet cutting. For instance, cutting stones underwater might be essential for people who want negligible noise during the cutting operation.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.