In the world of woodworking, the ability to push the boundaries of precision, creativity, and efficiency is a constant pursuit. For the determined DIY enthusiast or the aspiring woodworker, the opportunity to build your own CNC (Computer Numerical Control) wood router can be a transformative experience. By crafting a custom CNC router, you’ll unlock the power to take control of your woodworking projects, elevate your craftsmanship, and unlock new levels of innovation.

How to Build a CNC Wood Router

Building a CNC wood router can be a rewarding and fulfilling project for any woodworking enthusiast. If you are looking to take on this challenge, here are some general steps to guide you through the process:

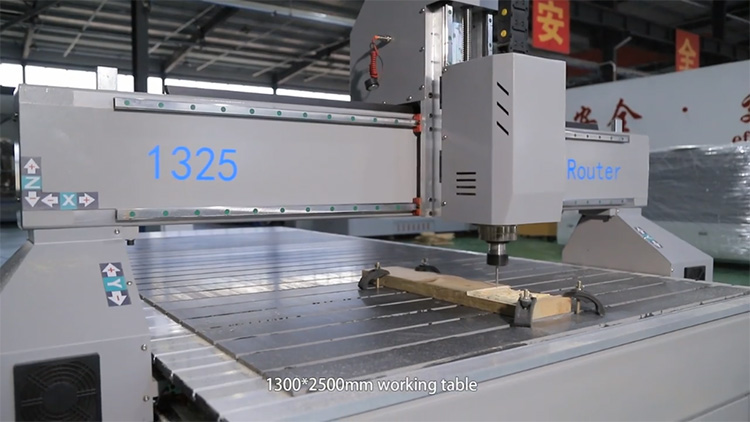

- Research and Planning: Start by researching different designs and types of CNC wood routers to determine the size and capabilities you want your machine to have. Consider factors such as cutting area, rigidity, and drive system.

- Gather Materials: Once you have a design in mind, gather all the necessary materials and components. This may include aluminum extrusions for the frame, stepper motors, lead screws or belts, linear guides, controller board, power supply, and spindle.

- Assembly: Begin assembling the frame of the CNC router according to your chosen design. Make sure to accurately square and align the frame to ensure the machine operates smoothly.

- Install Electronics: Install the stepper motors, controller board, power supply, and any other electronic components according to the manufacturer’s instructions. Make sure all connections are secure and properly wired.

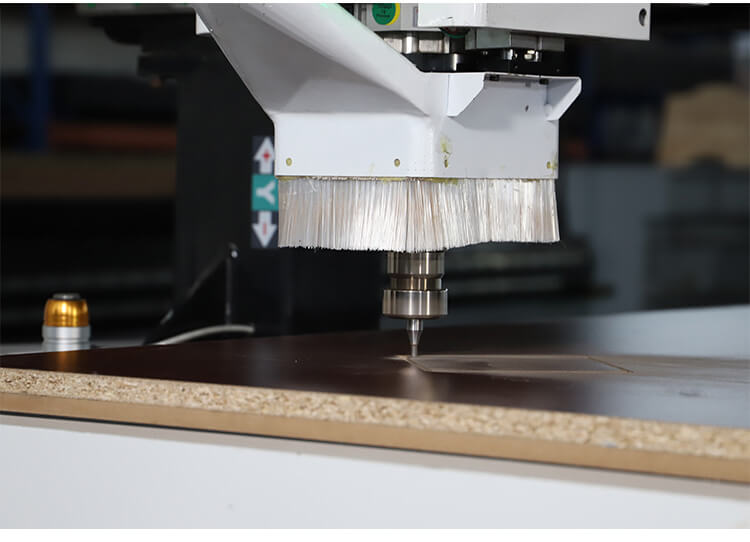

- Calibration: Once the machine is fully assembled, you will need to calibrate it to ensure accurate and precise cutting. This may involve adjusting the stepper motor settings, checking the alignment of the cutting head, and fine-tuning the software settings.

- Software Setup: Install the necessary software on your computer to control the CNC wood router. This may include CAM software for generating toolpaths and G-code, as well as a control program to communicate with the machine.

- Test Run: Before using the CNC wood router on a project, conduct test runs on scrap wood to ensure everything is working correctly. Make any necessary adjustments to the settings or calibration as needed.

CNC Wood Router Accessories list

Tube welding bed

More stable and effectively improves the rigidity and precision of the equipment.

Vacuum Table

A zoned vacuum tabletop is used to hold your work pieces in place when using a vacuum pump. CAMaster will rout out the vacuum tabletop with the appropriate number of zones and will install all plumbing, connections and valves for the operation of the vacuum table.

Phenolic Table Top

Phenolic is a non-porous material that is a great tabletop option for vacuum tables as it does not bleed any air. It is also a great option if you plan to cut aluminum as it will not absorb moisture and swell up from the lubricant used while cutting.

T‐Slot Clamping Table

Aluminum T‐Slot tracks are recessed into the machine tabletop. Clamps are also included which are slotted into the tracks to accommodate work pieces of different sizes.

Vacuum Table with T-Slot

A vacuum tabletop is combined with aluminum T‐Slot tracks. This gives you the ability to use either use a vacuum system or clamping to hold down your work pieces. Clamps are included and may be slotted into the tracks to accommodate work pieces of different sizes.

Vacuum Pod System

A vacuum pod system allows you lift your work piece off the main table to allow access to the edge of the piece for shaping or profiling. Vacuum pods are small blocks that act as vacuum hold down devices on a CNC vacuum table.

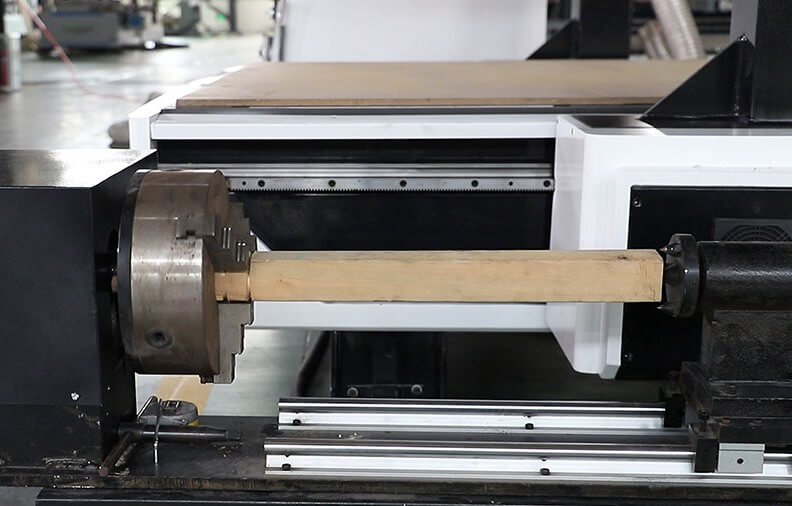

Recoil Indexing Lathe

The Recoil Indexing Lathe is used for full 3D carving. It mounted on the side of the machine and comes with a head stock, tail stock, rails, and motor/drive system. The tail stock is a removable, live center point. Can carve stock up to 6” diameter on the Stinger I, 10” diameter on the Stinger II and 12” diameter on the Stinger III and all Panthers. Indexing means that the work material can be rotated 360 degrees.

FAST TOOL CHANGE (FTC)

The FTC is a fast way to make frequent tool changes within a program. It comes with a “micro touch plate” mounted to the side of the table that measures the length of the new cutting tool and gives that information to the operating software making tool changes a “touch and go” operation.

Becker Vacuum Pump

This is a Rotary Vane pump. It is capable of creating a large amount of vacuum pressure (23 In Hg). Same as with the claw pump, a lower horsepower (8 to 10 HP) vane pump will generally outperform high horsepower regen blower systems for part holddown. The Becker pump operates on 3 Phase 220/460V Power

Black Box Vacuum Pump

The Hurricane, Cyclone and Storm Vacuum Systems operate on Single Phase 220-230V Power. This is ideal for small shops as it saves them from expensive phase converters or power drops. The Hurricane Vacuum System creates 9.5 In Hg and 400 CFM. The Cyclone Vacuum System creates 9.5 In Hg and 300 CFM. The Storm Vacuum System creates 9.5 In Hg and 190 CFM

Vision Registration System (VRS)

The CAMaster CutVision is a digital visual registration system that utilizes both software and a digital camera to automatically find and recognize conventional registration marks and adjust the machine’s cutting path as necessary to achieve exact cutting alignment with printed shapes. CutVision allows virtually any printed material to be accurately and precisely cut including card, vinyl, rubber, foam, wood, acrylic and many more.

Manual Spindles

HSD air cooled electro-spindle made in Italy. Each spindle comes with Spindle Speed Control which gives user precise control of Spindle RPM through the controller and Spindle On/Off, controlled via G‐ Code. The manual spindles are available in an ER20, ER25 or ER32 holder system based on HP Selected. Also includes 3 collets – 1/4”, 3/8″, and 1/2″.

Manual Spindles Options: 0.7 KW (1 HP), 1 KW (1.34 HP), 1.7 KW (2.28 HP), 3.0 KW (4.02 HP), 3.9 KW (5.22 HP), 7.0 KW (9.38 HP)

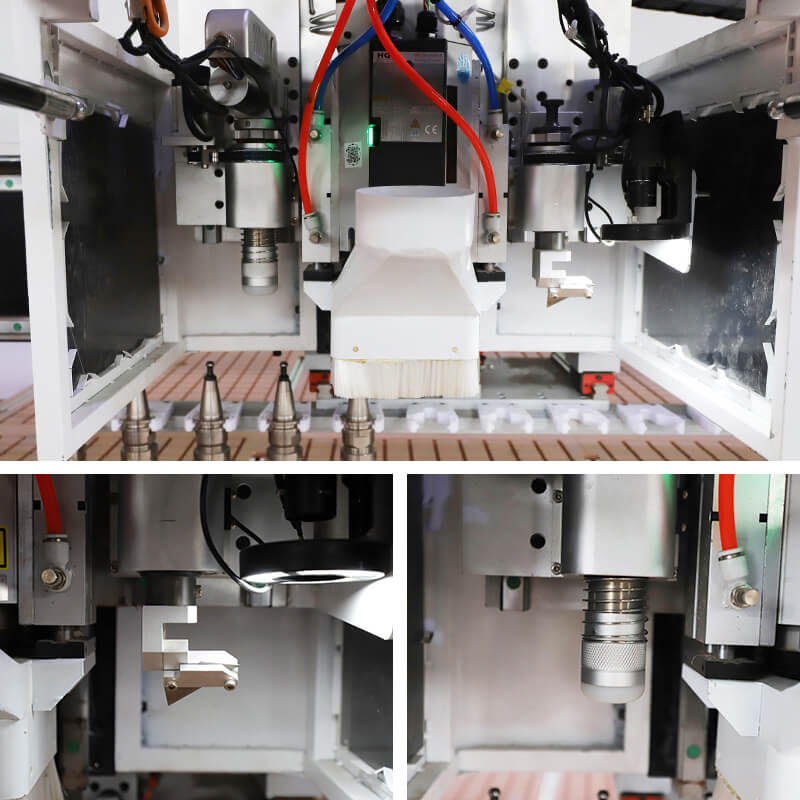

Aggregate Tool

Aggregate Tools are used to perform applications such as horizontal, or angled cutting and drilling. An aggregate tool attaches to the spindle in similar fashion as the tool holder does. A C-axis is available if you need to rotate the aggregate tool so that you can cut or drill on all sides

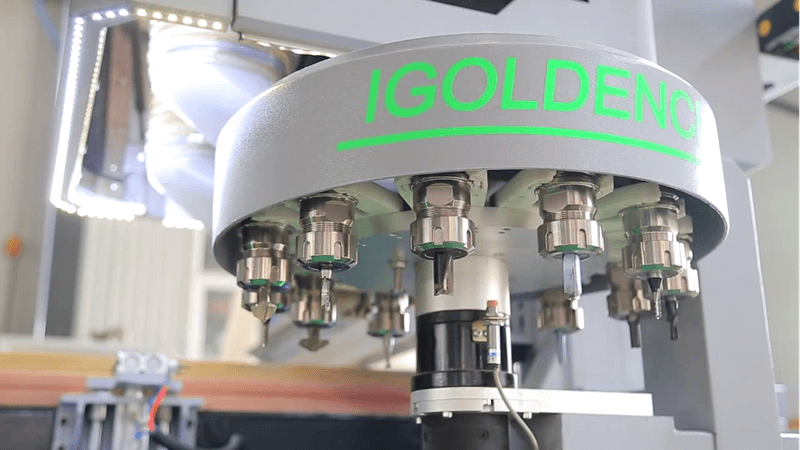

Automatic Tool Change (ATC) Spindles

HSD air cooled ATC spindles made in Italy. For the Cobra, each ATC spindle comes with 10 tool cones, 10 tool forks and 10 collets. For the Panther, 8 tool cones, 8 tool forks and 8 collets.

ATC Spindle Options: 5 HP (ISO-30), 12 HP (ISO-30), 16 HP (HSK-63F)

Linear Tool Rack

The linear tool rack comes with the automatic tool change feature. The tool rack holds 10 tools including an aggregate tool.

Rotary Tool Carousel

A gantry mounted Rotary Tool Carousel enables quick tool changes plus it gives the operator the ability to load and unload from all sides of the machine.

Drill Bank

A Drill Bank is used to speed up the hole drilling process using a CNC Router. Drill heads are available in a 5 position or a 9 position. Ideal option for cabinet makers, custom millworkers, exhibit and display manufacturers who are process a large number of sheets.

Laser Engraver

A high powered 7W laser that is fully integrated to the CNC machine. The laser is capable of both vector engraving and raster engraving. The laser will engrave multiple types of materials including wood, plastics, foam, paper, cardboard, rubber, leather, ceramic, anodized aluminum, PVC, vinyl, acrylics and more.

Oscillating Knife

An Oscillating tangential knife is designed to provide high accuracy cutting of soft and semi rigid materials including but not limited to Graphic Foam boards, Closed Cell Foam, Plastic-covered Foam, Corrugated Cardboard, Plastic, Gasket Materials, Rubber, Cork, Carpet, Felt, Vinyl and more. Comes standard with an air permeable cutting mat that is placed on the tabletop of your CNC machine when using the knife. Air permeability allows the mat to be used while using a vacuum system.

Tangential Knife

A non-oscillating tangential knife is designed for cutting heavier, thicker and harder materials. It comes with a gliding shoe that is used to hold down the material when cutting and can be adjusted depending on the holding force required. Comes standard with an air permeable cutting mat that is placed on the tabletop of your CNC machine when using the knife. Air permeability allows the mat to be used while using a vacuum system.

Interchangeable Knife System

This allows you to quickly swap between three different knife modules including the Oscillating Knife, Tangential Knife, and the Creasing Wheel. You can get one module with the purchase of the machine and as the need arises, simply add different modules with no hardware or software changes.

Popup Locating Pins

Pop up locating pins are the most reliable method of ensuring quick and easy material positioning. Your machine is configured with three pneumatically controlled pins. The heavy-duty pins are integrated to the deck of the machine and will withstand the repeated impacts of locating materials for the life of the machine.

Automatic Lubrication System

The CAMaster Auto Lube System ensures the CNC router’s bearings and ball screw are properly and automatically lubricated. Lubrication occurs while the machine is in operation which reduces downtime and the right amount of grease is applied to each component every time, removing the guess work on maintenance.

Mister System

The Mister System provides a cost-effective solution for cutting nonferrous metals. When used in non-ferrous cutting applications, the Mister System dispenses small amounts of Micro-Drop synthetic or vegetable-based lubricant to cool and lubricate the cutting tool. A phenolic top is recommended as it will not absorb moisture from the lubricant used while cutting.

Wireless Keypad

A wireless keypad allows the machine operator to run the machine wirelessly up to 300 ft.

Handheld Keypad

The Remote Handheld Keypad is a great way to operate your CNC Control PC without having to use a cumbersome keyboard. The keypad connects to your PC via a 15′ USB cable. The keypad comes with 20 pre-programmed buttons.

Extended Gantry Clearance

For applications that need a higher gantry clearance such as mold making or three-dimensional carving, extended gantry clearances 10″ – 24″ are available on our Cobra Elite.

Conclusion

Embarking on the journey of building your own CNC wood router is a thrilling and empowering experience that can revolutionize your woodworking endeavors. By following this step-by-step guide and harnessing your creativity, technical skills, and determination, you’ll unlock a world of precision, efficiency, and innovation in your craft. Whether you’re a seasoned woodworker or a passionate DIY enthusiast, crafting your own CNC router will undoubtedly transform the way you approach your projects and propel your woodworking to new heights.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.