Hot Wire Foam Cutter CNC

A foam hot wire cutter is an essential tool for businesses and individuals working with foam materials. Its ability to create precise, intricate designs and handle a variety of foam types makes it invaluable for industries like construction, advertising, and model-making. By choosing the right machine and features, you can streamline your workflow, reduce costs, and achieve professional-quality results.

Hot Wire Foam Cutter Video

Foam Hot Wire Cutter Parameter

| Technical indicators | parameter |

| Model | iGF-C |

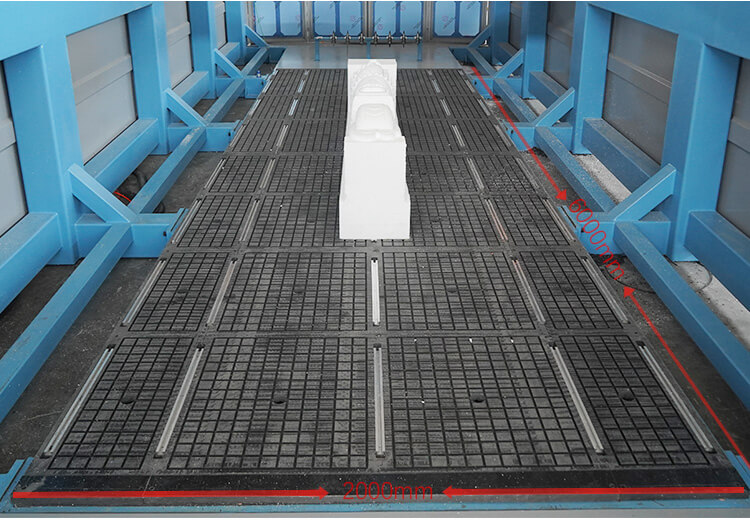

| Working Area | 3000*1300*1300mm |

| Cutting accuracy | ±0.2mm |

| File format | G code |

| Table structure | Thickened square tube welding (fine milling of rack guide surface five-sided machining center) |

| Working voltage | AC220V/50HZ (Foreign voltage can be customized) |

| Drive mode | X axis: Double high precision 20# square rail and a high precision 1.25m helical rack drive |

| Y axis: Double high precision 20# square rail with a Taiwan TBI ball screw drive | |

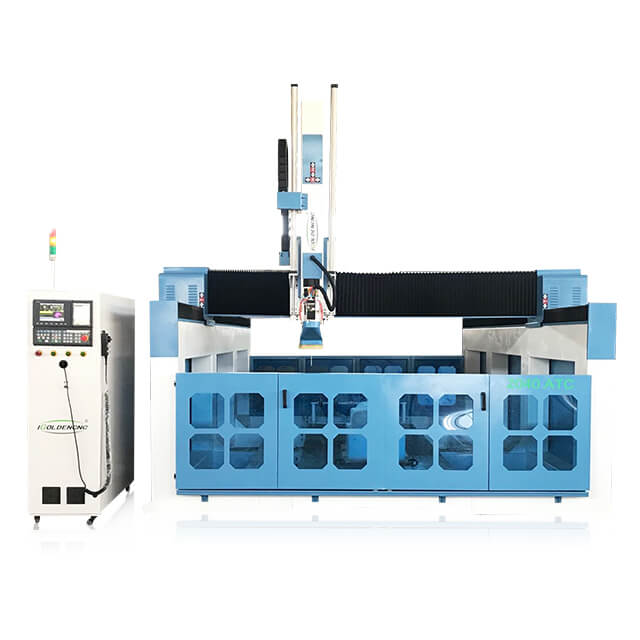

| Gantry | Widened and thickened profile (double gantry with beam support column) |

| Mapping software | CaxaCAD |

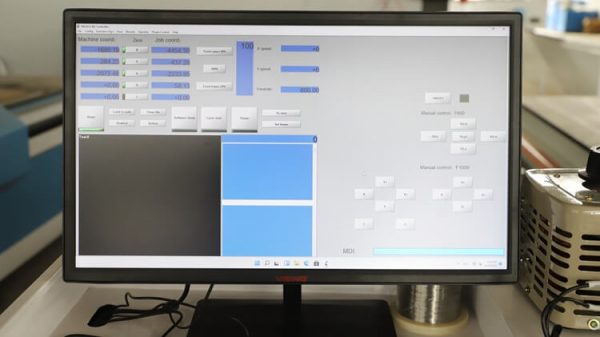

| Control system | MACH3 |

| Drive motor | Stepper motor |

| Control cabinet | New exit independent cabinet |

| Working Table | 20mm thick high density polyester board (finishing milling center), high flatness and high temperature resistance |

| Voltage regulator power | 1KVA |

| Bed weight | 800KG |

| Model | iGF-C |

| Working Area | 3000*1300*1300mm |

| Cutting accuracy | ±0.2mm |

If you need more detailed information, please inform us as soon as possible.

Independent gantry design

CNC machining machine with independent gantry design, gantry can be batch cutting benzene board materials. All mounting surfaces are machined to ensure accurate operation.

Taiwan lead screw and square rail

Transmission system adopts Taiwan ball screw and straight square rail, precise transmission without clearance, low noise, higher life and accuracy.

Service platform

Using cutting software CAXA and AUTOCAD drawings, without scanning, import can be cut, and has online simulation function, very convenient to use, software operation is simple and easy to learn.

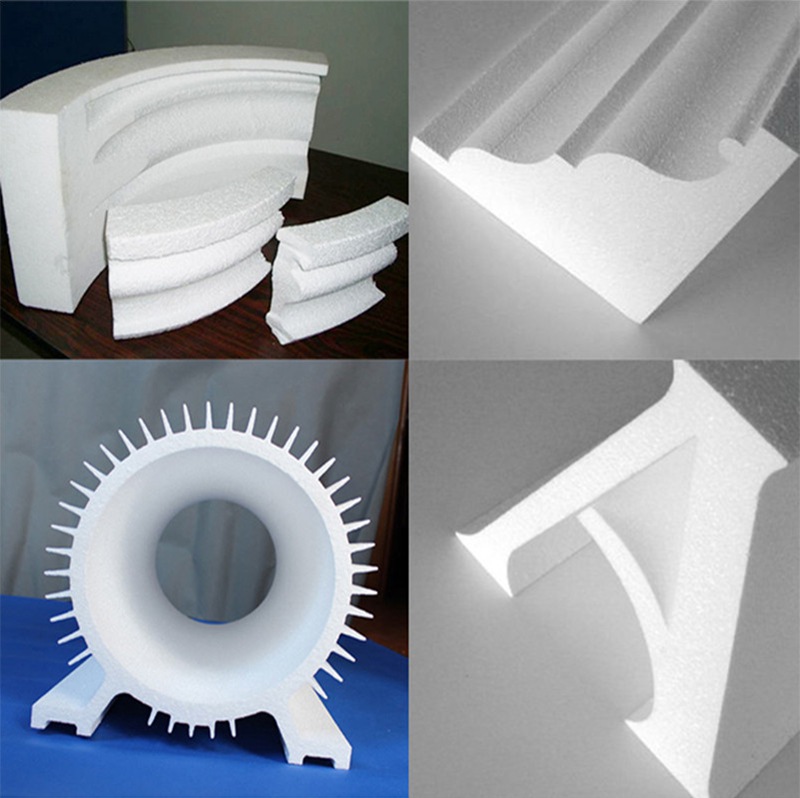

Clean Cuts

Produces smooth, clean edges without tearing or crushing the foam, which is crucial for finished appearances.

Key Features of Hot Wire Foam Cutters:

Heating Wire: The wire gets heated electrically and melts the foam as it’s cut.

Precision: Allows for detailed cuts and intricate shapes, often used in crafting, model making, or even in insulation applications.

Adjustable Temperature: Some models allow you to control the temperature, which helps when working with different foam densities.

Variety of Shapes: Hot wire foam cutters come in several shapes and sizes, including handheld models and larger table-mounted versions.

Speed: Cuts foam quickly, making it efficient for large projects or production work.

Low Waste: The melting process minimizes waste and mess compared to traditional cutting methods.

Hot Wire Foam Cutter CNC Application

Hot wire CNC foam cutters allow creating practically any product of the most complicated shape in a fast, accurate and relatively inexpensive way. Hot wire CNC foam cutting machines is used to create display letters, logos (3D Logos), raphics, signboards, labels for indoor and outdoor ads, decor elements, fair stalls, store props & displays, P.O.P. displays, decorations for the theater or cinema, mock-up products, all kinds of packaging, amusement, architectural shapes, large-scale architecture models, thematic props, pipe insulation, preCast concrete molds, columns, etc.

The cutter consists of a thin wire, usually made of nichrome, which heats up when an electric current passes through it. The heated wire melts the foam upon contact, allowing for effortless cutting and shaping.

Key Components of a Hot Wire Foam Cutter

- Nichrome Wire – The heated wire that cuts through the foam.

- Power Supply – Provides the necessary voltage to heat the wire.

- Adjustable Temperature Control – Allows for different heat settings based on foam type.

- Cutting Frame or Table – Provides stability for precise cuts.

There are different types of hot wire foam cutters, each designed for specific applications:

1. Handheld Hot Wire Cutters

- Ideal for freehand cutting and shaping.

- Best for small projects and DIY applications.

2. Tabletop Hot Wire Cutters

- Provides stability for precise, straight cuts.

- Suitable for model-making, signage, and industrial applications.

3. CNC Hot Wire Foam Cutters

- Computer-controlled for automated, intricate designs.

- Used in large-scale production and architectural modeling.

When selecting a hot wire foam cutter, consider the following factors:

1. Cutting Size and Capacity

- Choose a cutter that can accommodate the size of foam you typically work with.

2. Adjustable Temperature Control

- Some foams require different heat levels for optimal cutting.

3. Power Supply and Voltage

- Ensure the power supply matches your region’s voltage requirements.

4. Durability and Build Quality

- Look for a cutter with a sturdy frame and high-quality nichrome wire.

5. Safety Features

- Insulated handles, automatic shutoff, and heat-resistant materials enhance safety.

Most hot wire foam cutters work best with polystyrene (EPS and XPS) but may not be suitable for polyurethane or polyethylene foams without adjustable temperature settings.