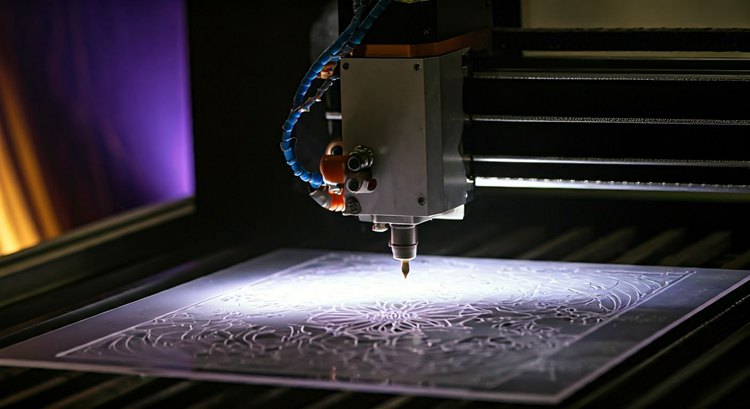

A Computer Numerical Control (CNC) Router is a computer-controlled cutting machine that uses a high-speed rotating spindle to cut, carve, engrave, and shape a wide variety of materials.

What is a Computer Numerical Control Router?

A Computer Numerical Control (CNC) router is a precision manufacturing machine that uses computer-controlled cutting tools to shape, carve, and cut various materials with exceptional accuracy. Unlike traditional manual routing tools, CNC routers operate through programmed instructions, making them indispensable in modern manufacturing, woodworking, and fabrication industries.

How CNC Routers Work: The Technology Behind Precision

CNC routers operate on a simple yet sophisticated principle. The machine receives digital design files, typically in G-code format, which contain precise instructions for tool movement, speed, and cutting depth. The router’s spindle motor drives cutting bits along predetermined paths, controlled by servo motors and linear guides that ensure accuracy within thousandths of an inch.

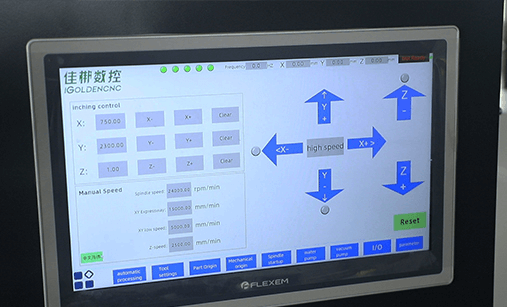

The three-axis system (X, Y, and Z) allows the cutting tool to move horizontally and vertically, while advanced models feature additional axes for more complex operations. This computer-controlled precision eliminates human error and enables consistent, repeatable results across thousands of parts.

Key Components

-

CNC Controller – Receives G-code instructions and drives the machine.

-

Spindle (Router Head) – High-speed motor that holds the cutting tool.

-

Worktable (Bed) – Where the material is fixed (can be vacuum, clamp, or T-slot table).

-

Axes of Motion:

-

X-axis – left/right movement

-

Y-axis – forward/backward movement

-

Z-axis – up/down movement

-

Advanced machines may include 4th (rotary) or 5th axis for more complex shapes.

-

-

Software – CAD for design + CAM for toolpath + machine interface.

Types of CNC Routers: Choosing the Right Machine

Desktop CNC Routers

Perfect for hobbyists, small businesses, and prototyping, desktop CNC routers typically handle materials up to 12″ x 12″ x 4″. These compact machines offer affordability and ease of use while maintaining professional-quality results for smaller projects.

Industrial CNC Routers

Designed for high-volume production, industrial CNC routers feature robust construction, larger work areas, and powerful spindles. These machines can handle full-size sheets of plywood, aluminum, and other materials, making them ideal for furniture manufacturing, sign making, and architectural millwork.

Multi-Axis CNC Routers

Four-axis and five-axis CNC routers add rotational capabilities, enabling complex curved cuts and 3D sculpting. These advanced machines excel in aerospace, automotive, and artistic applications where intricate geometries are required.

Axis of CNC Routers

-

3-Axis CNC Router: Standard, for flat sheet work and relief carving.

-

4-Axis CNC Router: Adds rotary axis for columns, statues, cylindrical carving.

-

5-Axis CNC Router: High-end, for complex 3D shapes and multi-angle cutting (aerospace, mold, and advanced stone/woodwork).

-

ATC CNC Router: With Automatic Tool Changer, improves productivity by switching tools automatically.

Applications

Woodworking – Cabinets, doors, signs, furniture, decorative panels.

Advertising & Signage – 3D signs, acrylic letters, foam models.

Stone & Marble – Countertops, tombstones, sculptures (using stone CNC router).

Metal & Aluminum – Molds, parts, light industrial fabrication.

Plastics & Composites – Acrylic sheets, carbon fiber, PVC, ABS panels.

Applications Across Industries

Woodworking and Furniture Manufacturing

CNC routers revolutionize traditional woodworking by enabling complex joinery, decorative panels, custom cabinetry, and intricate inlays. Furniture manufacturers use these machines for consistent production of components like chair backs, table legs, and decorative elements.

Sign Making and Graphics

The sign industry relies heavily on CNC routers for cutting dimensional letters, engraving plaques, and creating complex layered signs from various materials. The precision enables fine detail work impossible with manual methods.

Prototyping and Product Development

Engineers and designers use CNC routers for rapid prototyping, allowing quick iteration of designs and functional testing before committing to expensive tooling for mass production.

Aerospace and Automotive

These industries demand the precision and repeatability that CNC routers provide for creating jigs, fixtures, and specialized components from advanced materials.

Key Benefits of CNC Router Technology

Precision and Consistency: CNC routers achieve tolerances as tight as ±0.001″, ensuring every part matches specifications exactly.

Increased Productivity: Automated operation allows 24/7 production capabilities, dramatically increasing output compared to manual methods.

Design Flexibility: Complex geometries, intricate patterns, and custom shapes become easily achievable through CAD/CAM software integration.

Material Efficiency: Optimized nesting software minimizes waste by arranging parts efficiently on raw materials.

Safety Improvements: Enclosed cutting areas and automated operation reduce operator exposure to cutting tools and dust.

IGOLDENCNC Router Types Comparison

| CNC Router Type | Axes | Main Functions | Applications | Price Range (USD) | IGOLDENCNC Example |

|---|---|---|---|---|---|

| 3-Axis CNC Router | X, Y, Z | Cutting, engraving, drilling on flat surfaces | – Cabinet doors- 2D & relief carving- Wood signs- Panel processing | $3,000 – $10,000 | iGC-L series (Wood CNC Router) |

| 4-Axis CNC Router | X, Y, Z + A (rotary/tilt) | Can rotate the workpiece or spindle for 3D machining | – 3D sculptures- Furniture legs- Stone statues- Cylindrical carving | $8,000 – $20,000 | iGW-4A (4-Axis Stone/Wood Router) |

| 5-Axis CNC Router | X, Y, Z + A, B (multi-angle) | Full 3D machining with complex curves and angles | – Aerospace & auto molds- High-end countertops- Advanced stone cutting- Boat & aircraft parts | $35,000 – $120,000+ | iG5A series (5-Axis ATC CNC Router) |

| ATC CNC Router (Automatic Tool Changer) | X, Y, Z (can be 3, 4, or 5 axis with ATC) | Automatically switches tools, saving time in multi-step jobs | – Cabinet production- Furniture factories- Complex mold fabrication | $15,000 – $60,000 | iGW-ATC (Wood & Stone ATC CNC) |

Which One Should You Choose?

-

Hobbyist / Small Business (signs, cabinets) → 3-Axis

-

Stone carving, furniture legs, 3D statues → 4-Axis

-

Aerospace molds, complex countertops, boat parts → 5-Axis

-

Mass production factory → ATC CNC Router

Selecting the Right CNC Router: Factors to Consider

Work Area Requirements

Determine the maximum size of parts you’ll machine. Consider both current needs and future growth when selecting table size.

Spindle Power and Speed

Higher horsepower spindles handle tougher materials and larger cutting tools. Variable speed control optimizes cutting parameters for different materials.

Accuracy and Repeatability

Look for machines with high-quality linear guides, precision ball screws, and robust construction that maintains accuracy over time.

Control System Features

Modern CNC controllers offer user-friendly interfaces, networking capabilities, and advanced features like tool change automation and part probing.

Conclusion: CNC Routers as Manufacturing Game-Changers

Computer Numerical Control routers represent a fundamental shift in manufacturing capabilities, combining traditional craftsmanship with modern precision and automation. Whether you’re a small woodworking shop looking to expand capabilities or a large manufacturer seeking efficiency improvements, CNC routers offer scalable solutions that grow with your business.

The technology’s continued evolution promises even greater capabilities, making now an excellent time to explore how CNC routing can transform your manufacturing processes. With proper selection, installation, and training, CNC routers deliver the precision, efficiency, and flexibility needed to compete in today’s demanding marketplace.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.