3-Axis VS 4-Axis

3-Axis Bridge Saw Capabilities and Advantages

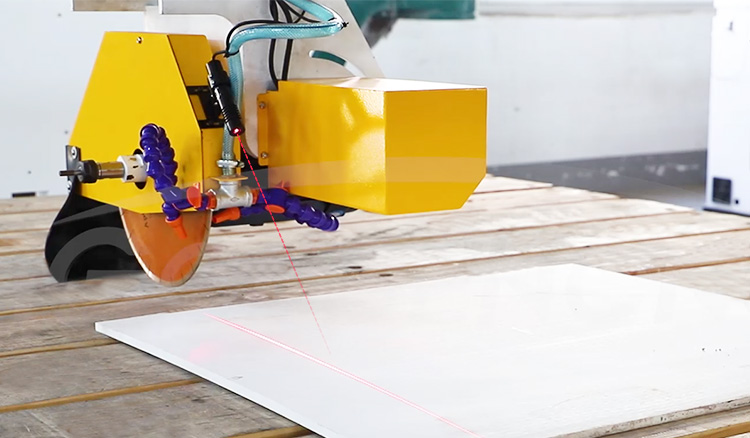

Comprehensive Standard Applications: 3-axis bridge saws handle all routine stone fabrication—kitchen countertops with sink cutouts, bathroom vanities, table tops, floor tiles, wall cladding, shower surrounds, and fireplace surrounds. These applications represent 85-95% of typical fabrication shop work, making 3-axis the industry workhorse.

Cut straight edges, create rectangular or curved sink openings, drill faucet holes, profile edges using dedicated tooling, and execute angled cuts for backsplashes or specialty applications. The overwhelming majority of residential and light commercial projects require nothing beyond 3-axis capability.

Cost-Effective Investment: 3-axis bridge saws cost 40-60% less than comparable 4-axis systems. For shops where standard fabrication work predominates, this economy delivers essential capability at affordable investment with faster ROI. The price differential often determines whether small to medium fabricators can afford CNC automation at all.

A quality 3-axis bridge saw provides decades of productive service handling consistent work volumes without the complexity premium of rotary blade positioning.

Operational Simplicity: Programming and operating 3-axis systems requires less specialized training. Operators achieve proficiency faster, daily setup procedures are straightforward, and troubleshooting is more intuitive. This simplicity benefits shops without extensive technical expertise or those preferring streamlined operations minimizing downtime.

Maintenance requirements are less complex without rotary mechanisms, reducing service costs and potential failure points. Shops in remote locations particularly value this reliability and self-sufficiency.

Speed for Standard Work: Without rotary axis positioning time, 3-axis systems often complete standard jobs faster through direct, efficient motion. Optimized linear cutting paths maximize productivity for the high-volume work that sustains most fabrication businesses.

Space Efficiency: 3-axis machines occupy less floor space without rotary head mechanisms. For shops with space constraints, this compact footprint provides critical advantages enabling CNC capability within existing facilities.

4-Axis Bridge Saw Advanced Capabilities

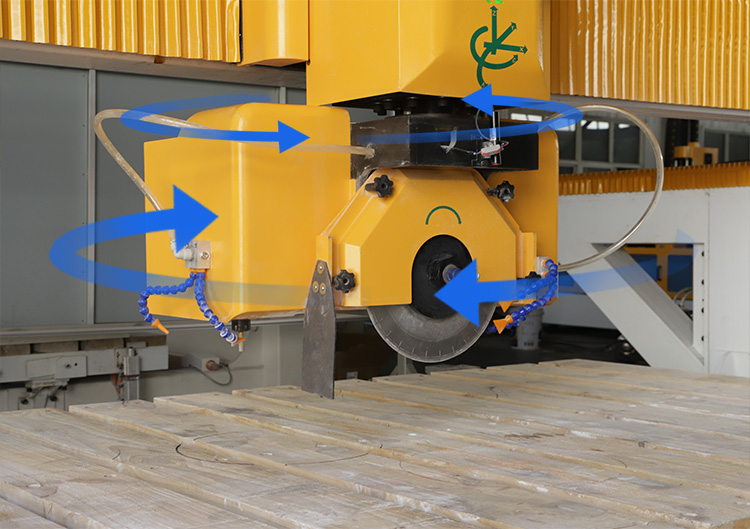

Mitered Edge Excellence: The defining advantage of 4-axis systems is flawless mitered edges at any angle. Contemporary kitchen designs increasingly feature waterfall edge countertops where vertical side panels meet horizontal surfaces at perfect 45-degree miters. 4-axis bridge saws cut both mating surfaces precisely, ensuring tight, seamless joints.

Traditional 3-axis methods require cutting miters on both pieces separately, then matching—a process demanding exceptional skill and often requiring grinding to achieve acceptable fit. 4-axis systems cut both surfaces in single setups with perfect complementary angles, eliminating fit-up challenges.

Complex Architectural Elements: Commercial projects, high-end residential work, and architectural applications involving compound angles, curved miters, or three-dimensional edge treatments justify 4-axis capability. Reception desks with curved mitered edges, sculptural elements, and contemporary designs with non-orthogonal geometry benefit enormously.

Single-Setup Efficiency: Projects requiring cuts at multiple angles complete without repositioning slabs between operations. This consolidation reduces handling (minimizing breakage risk with expensive materials), improves accuracy by eliminating cumulative positioning errors, and accelerates production for complex jobs.

Premium Market Positioning: 4-axis capability enables accepting projects that competitors with 3-axis equipment cannot handle economically. This differentiation supports premium pricing, attracts designers and architects seeking fabricators capable of executing sophisticated visions, and positions shops as technology leaders.

Reduced Manual Finishing: Precise automated miters require minimal grinding and polishing compared to manually fitted joints. This labor reduction partially offsets higher equipment costs while improving consistency and quality.

Conclusion

The 3-axis versus 4-axis decision for marble cutting depends fundamentally on your specific application mix. For the majority of marble fabricators focused on countertops, monuments, tiles, and flat architectural work, 3-axis systems deliver optimal value—providing necessary capability at reasonable investment with straightforward operation. The 4-axis premium only justifies when cylindrical components, complex 3D work, or specialized applications constitute significant business volume and command pricing premiums offsetting additional complexity and cost. Partner with iGoldenLaser to analyze your requirements realistically, ensuring your marble cutting investment matches your business needs perfectly—neither limiting capability through insufficient axes nor wasting resources on complexity you’ll rarely utilize.

The advantages of the 4-axis machine for more detailed marble cutting are clear. One thing I’d like to add is that while the 4-axis model offers more flexibility, operators need to have more technical expertise to fully leverage its potential, especially in marble cutting.