If you’re evaluating a CNC router upgrade for a production line or a busy shop, two popular high-throughput options often compete for attention: ATC CNC routers (automatic tool changer) and multi-head CNC routers (multiple spindles/heads on one bed). Both approaches are designed to boost productivity, reduce manual tool changes, and expand the range of parts you can manufacture. This guide explains what each system is, how they differ in practice, and which setup best fits your workload, materials, and budget.

What is ATC CNC Router?

ATC stands for automatic tool changer. An ATC CNC router adopts an electric spindle which automatically loosens or clamps tools by the movement of the internal cylinder. And the electric ATC spindle quickly auto changes the cutting tools without stopping work. An ordinary CNC router only adopts one cutting bit on the spindle. And the operator needs to stop the machine and then manually replaces the tool, which affects the processing efficiency in a negative way. The invention of automatic tool changer CNC router represents the most technological CNC router. It changes tools automatically and greatly saves the processing time and manpower.

The intelligent tool change function of the machine depends on the control system and tool magazine. The control system controls the movement of gantry and spindle. And the tool magazine carries multiple cutting tools. When a tool completes its machining work, the spindle moves to the tool magazine and releases the tool. Next, it automatically grabs the next tool for subsequent processing. Automatic tool changer function is the final trend of CNC router development. It is the best choice for large and medium-scale processing projects.

There are two types of tool magazines: linear tool magazine and disc tool magazine.

Linear Tool Magazine

Linear tool magazine is a linear device on which there are multiple cutting tools are adopted. This tool magazine can be installed under the gantry or behind the workbench according to user’s requirements. For example, if the user wants to change tools faster, the manufacturer can install the tool magazine under the gantry. If the user wants to leave enough processing area, the tool magazine can be installed behind the workbench. Watch below video to see the working demonstration of ATC CNC router with linear tool magazine.

Disc Tool Magazine

Unlike linear tool magazine, disc tool magazine completes the tool switching through its own rotation. The tools on the tool magazine are installed parallel to the center of the spindle. Disc tool magazine can be installed in different positions according to user’s requirements. And the tool switching process just takes a few seconds. Watch below video to see the working demonstration of ATC CNC router with disc tool magazine.

Both linear tool magazine and disc tool magazine can greatly improve the processing efficiency and save labor costs for users. Moreover, ATC CNC machine can adapt to complex processing occasions and improve the quality of products. And the user doesn’t need to load and unload work pieces frequently. This machine has a wide range of applications in cabinet making, wooden door carving, screen carving, advertising sign engraving, home decoration, crafts, foam molding, metal engraving and many other fields.

What is Multi Head CNC Router?

Multi head CNC router has multi spindles. A multi head CNC router usually adopts 2 to 4 spindles and each spindle carries a cutting tool. The external cylinder controls the movement of the spindles, and the spindles work in turn to process the work pieces. Multi head CNC router is like a simple ATC CNC router. It automatically switches cutters by changing its spindles.

The multi spindles can realize seamless switching during the machining process. After a spindle finishes its work, it moves to the beam and the next spindle starts to work at the same time. Watch the video below to learn how a multi head CNC router switches spindles quickly. As you can see from the video, multi head CNC router changes cutters by changing spindles. In this way, multiple processes can be completed on one machine. It greatly improves the processing efficiency.

Multi head CNC router can process cabinets, wardrobes, beds, doors and shows higher efficiency and precision than ordinary CNC router that only adopts one spindle. It can also perform woodworking artwork carving, which is not possible to finish with an ordinary wood CNC router. Moreover, the machine integrates various processes into one process. It greatly avoids the bumps and damage to the work pieces caused by multiple manual loading and unloading processes. In addition, with the redundant spindles adopted, even if one spindle is broken, the machine can continue to work.

ATC CNC Router vs. Multi Head CNC Router

Next I will make a comprehensive comparison between ATC CNC router and multi head CNC router. The two machines have some similarities and obvious differences.

Similarities

No matter ATC CNC router or multi head CNC router, both of the two machines are CNC router machines. So they have the following similarities:

1.Similar working principle

Both of the two machines are woodworking engraving machines controlled by software. The software generates instructions to control the movement of the beam and the rotation of the spindle. And both of the two machines need user to import tool path and set proper parameters. And the processing is automatic with little human intervention.

2.Similar machine appearance and basic structure

Both of the two machines are CNC routers, so the appearance of these two machines is similar to ordinary CNC router. Besides, in terms of basic structure, the two machines both include worktable, beam, controller, spindle, drive, motor and other parts that a common CNC router has.

3.Higher processing efficiency than ordinary CNC router

No matter ATC CNC router or multi head CNC router, both of the two machines have higher processing efficiency than ordinary CNC router. This is because the two machines can auto change cutters and no need manual tool change. And both of the two machines can complete multiple processing steps at one time. Without frequent loading and unloading processes, the two machines perform higher processing efficiency than ordinary CNC routers.

4.Higher processing precision than ordinary CNC router

Both of the two machines can finish multiple processing work without stopping work and reduce the scratches caused by manual loading and unloading. This ensures the higher processing precision.

Differences

ATC CNC router and multi head CNC router were created according to different processing needs, so they have the following differences that need your attention:

| Differences | ATC CNC Router | Multi Head CNC Router |

| Tool change principle | Changes tools by the movement of the internal cylinder | Changes cutters by the movement of the external cylinder |

| Configuration | Syntec control system Siemens control system Italy HSD ATC spindle HQD spindle Siemens servo motor Leadshine servo motor Delta inverter Japan YASKAWA servo motor |

LNC control system Syntec control system DSP control system Dongling servo motor HQD spindle HANQI spindle BEST inverter |

| Price | About $10,000 to $35,000 | About $8,000 to $15,000 |

| Processing precision | High processing precision | Lower processing precision than ATC CNC router |

| Processing range | Various applications: Furniture making Advertising Musical instrument Home decoration Foam molding Crafts making |

Furniture making: Cabinets Doors Beds Wardrobes Bookcases |

| Processing material | Various processing materials: Wood, Plywood MDF Acrylic Plastic Leather Stone Aluminum Brass Foam Fabric |

Wooden materials: Solid wood Artificial wood Plywood MDF |

| Processing effect | Various processing effects: Cutting Engraving Drilling Milling Punching Grooving Boring |

Cutting Engraving Drilling |

Which Machine to Choose?

As I just mentioned, ATC CNC router and multi head CNC router have different configuration and processing performance. Therefore, their applicable processing ranges are different. On the one hand, ATC CNC router is very popular in many industries including furniture, advertising, crafting, musical instruments, molding, etc. On the other hand, multi head CNC router is cheaper and mainly used in the furniture making industry. So which machine to choose? In the following content, I will introduce the applications of the two machines separately.

- Choose ATC if:

- Your jobs require many different tools in a single part (e.g., engraving, pocketing, v-carving, and finishing in one program).

- You want longer, unattended runs with minimal operator intervention.

- You have a broad library of tools and CAM workflows that benefit from automated tool changes.

- Your typical parts are moderate in size and require diverse operations but don’t need parallel heads.

- Choose Multi-Head if:

- Your production profile benefits from parallel or sequential multi-head operations (e.g., drilling and routing simultaneously on large panels).

- You frequently run high-volume, multi-feature parts where reducing overall cycle time is crucial.

- You have the space and budget to accommodate multiple spindles and the associated control complexity.

- You want redundancy or the ability to run complementary processes in tandem without changing tools mid-job.

Applications of ATC CNC Router

ATC CNC router finds great popularity in various industries, including but not limited to furniture, advertising signs, foam molds, crafts, musical instruments and so on.

Furniture

In the furniture industry, woodworking CNC router can process solid woods or artificial woods to make cabinets, doors and other furniture. ATC CNC router can switch tools quickly without stopping work and deal with various furniture styles. It can process European-style furniture, American-style furniture and retro Chinese-style furniture that have complex patterns. The ATC device enables the machine to complete various carving techniques including contour, curve, arc, etc. And its product reflect a gorgeous and noble look. ATC CNC router is able to engrave exquisite patterns on the furniture and make high-end wooden furniture.

ATC CNC router has the function of cutting, engraving, grooving, drilling, etc. This machine can not only process common furniture like cabinet and doors, but also can make wave boards, screens for indoor decoration. The picture below shows some furniture made by IGOLDENCNC users with ATC woodworking CNC router. The ATC CNC router helped them expand business scope and brought more profits.

Advertising Signs

In the advertising industry, CNC routers are mainly used to make advertising signs of various materials. If you need a machine to make billboards, a CNC router with automatic tool changer is an ideal choice. This machine can process PVC board, acrylic board, ABS board and other materials which are used to make advertising signs.

The ATC CNC router is equipped with an intelligent control system. Users design the tool path and auto change, and then the machine completes all the processing steps at once. ATC CNC router has high efficiency in the processing of billboards and it saves a lot of labor costs. Users can process different types of advertising signage, logos, plastic molding plates or brand trademarks. In addition, users can customize the signs according to the needs of their customers. The processed signs have both aesthetics and practicality. They can attract more visitors and perfectly promote the business.

Foam Molds

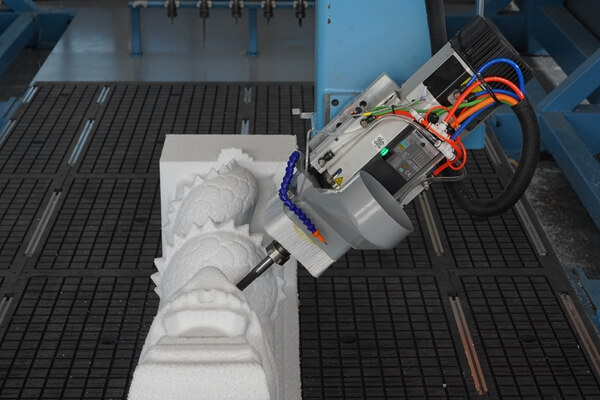

In the foam molding industry, a CNC router that has automatic tool changer is more efficient. The CNC router for foam processing industry is mainly to process 3D carving and make foam molds, foam sculptures, etc. These foam products can be used in automobile exhibitions, mechanical modeling and art exhibitions. Foam processing requires good processing efficiency and flexible processing methods. And 3D foam carving needs different types of cutting tools to finish the work. Therefore, ATC CNC router is more capable to meet complex foam carving needs. ATC CNC router switches tools to realize different processing styles without stopping work. It can perform multiple effects on the foam including cutting, carving, drilling, grooving, etc.

Crafts

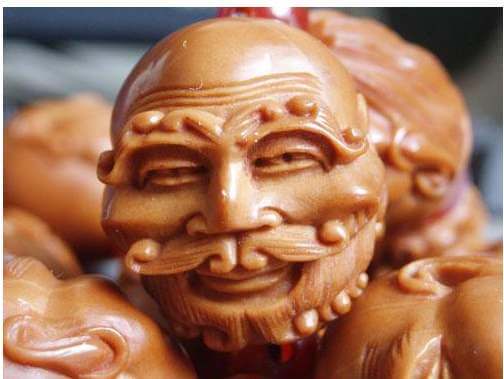

There are many ideal materials to make high-end crafts, such as wood, plastic, aluminum, stone. All of them can be made by ATC CNC router. The making of crafts needs the cutting machine more flexible and can handle complex processing effects. Automatic tool changer CNC router has unique advantages in the processing of crafts. It provides different cutting tools which engrave the materials in various styles. The crafts and made by automatic tool changer CNC router are exquisite and amaze visitors. They can be used to decorate buildings, offices, hotels and houses.

Musical Instruments

If you’re a musical instrument maker, the ATC CNC router definitely can help you to make exquisite musical instruments. It can cut and engrave on the materials and leave beautiful arcs and smooth cutting edges. Moreover, the machine can carve exquisite patterns on the surface of musical instrument and make it more attractive and beautiful. ATC CNC router is the most ideal machine to make musical instruments for manufacturers and enthusiasts. It can easily produce 2D and 3D shapes and components for guitar construction, helping users mass-produce the body and neck. And it can customize personalized guitars and various types of musical instruments.

Technical Considerations: Spindles, Tools, and Control

- Spindle power and torque:

- ATC: Focused on a versatile tool library; ensure the spindle power matches your material types and depths.

- Multi-Head: Each head’s spindle power should align with its intended task (roughing, finishing, drilling).

- Tool changer vs head synchronization:

- ATC relies on a tool magazine and an automated changer mechanism.

- Multi-head requires sophisticated synchronization to avoid collisions and ensure coordinated moves.

- CAM and control software:

- ATC workflows benefit from CAM that can sequence tool changes efficiently.

- Multi-head CAM must manage tool assignments across heads, head offsets, and collision checks.

- Maintenance and reliability:

- ATC adds moving parts (magazine, changers) that require periodic calibration and parts replacement.

- Multi-head adds multiple spindles/head assemblies, alignment checks, and potential vibration management.

Conclusion

Both ATC CNC routers and multi-head CNC routers offer powerful paths to higher productivity, but they fit different production philosophies. If your work demands a wide tool library, minimal tool-change downtime, and reliable repeatability, an ATC router is often the smarter choice. If your priority is maximizing throughput on large, multi-feature panels with parallel processing, a multi-head setup can deliver substantial cycle-time improvements—provided you’re prepared for the added complexity and cost. By aligning your choice with your workloads, CAM workflows, and maintenance capabilities, you can pick the solution that delivers the best return for your shop.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.