Australia’s stone fabrication market continues to demand higher precision, better material utilization, and faster turnaround. A Stone CNC Bridge Saw combines large-format cutting with CNC control, enabling accurate slab sizing, profiling, and beveling in a single setup. Whether you’re producing countertops, vanity tops, architectural panels, or sculpture components, a bridge saw with CNC capability can boost throughput and consistency. This guide covers what to look for when buying a Stone CNC Bridge Saw in Australia, from configuration and specs to software workflows, maintenance, and total cost of ownership.

Understanding Stone CNC Bridge Saws

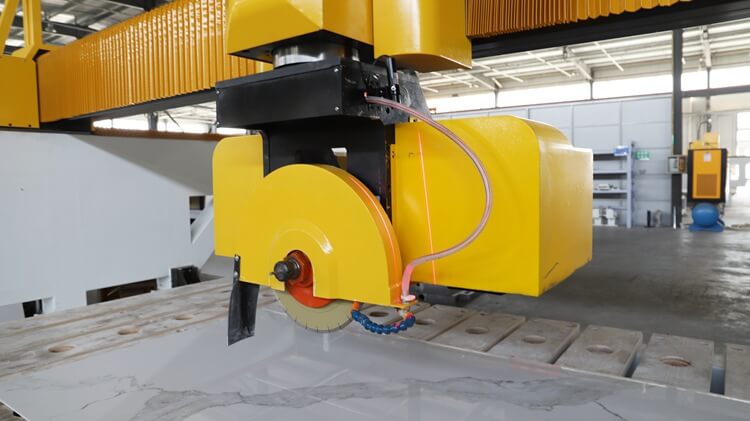

A CNC bridge saw represents the pinnacle of stone cutting technology, combining computer-controlled precision with robust mechanical design to cut granite, marble, quartz, and engineered stone with exceptional accuracy. The “bridge” design features a gantry structure spanning the cutting table, with the cutting head traveling along rails above the stone slab. This configuration provides stability, precision, and access to cut anywhere within the work area.

CNC control transforms bridge saws from manual positioning devices into precision manufacturing tools. Operators input dimensions digitally, and the machine executes cuts with repeatability impossible to achieve manually. This automation dramatically increases productivity while reducing material waste and operator fatigue.

Key Features of IGOLDENCNC Bridge Saws

Heavy-Duty Construction: Fabricated from high-grade steel with precision-machined components, our bridge saws deliver the rigidity essential for accurate stone cutting. Granite and engineered stone generate substantial cutting forces—our robust frames maintain accuracy under these demanding conditions.

Advanced CNC Control Systems: User-friendly control interfaces with intuitive programming minimize learning curves. Import CAD files directly, create cutting programs at the machine, or use our library of common shapes and dimensions. Touch-screen controls simplify operation while maintaining sophisticated functionality.

Powerful Cutting Heads: High-torque motors driving diamond blade assemblies cut through the hardest materials efficiently. Adjustable blade speed and feed rate optimization ensures clean cuts across material types from soft marble to dense granite and engineered quartz.

Precise Linear Motion: High-quality linear guides and ball screw drives deliver positioning accuracy within 0.1mm. This precision ensures perfect miters, accurate dimensions, and seamless joints that define quality stone installation.

Integrated Water Management: Efficient cooling and lubrication systems extend blade life while suppressing dust. Integrated water recycling reduces consumption—important in water-conscious Australia. Effective chip and slurry removal maintains cutting accuracy and simplifies cleanup.

Safety Features: Comprehensive safety systems including emergency stops, blade guards, and interlock systems protect operators. Australian safety standards compliance ensures workplace safety requirements are met.

Applications in Australian Stone Fabrication

Kitchen Benchtops: Precise cutting of granite, marble, and engineered stone for residential and commercial kitchens. Perfect miters, accurate cutouts for sinks and cooktops, and consistent dimensions ensure quality installations that satisfy demanding Australian homeowners.

Bathroom Vanities: Custom vanity tops, shower bases, and wall panels cut to exact specifications. The precision enables seamless corners and perfect fits in renovation and new construction projects.

Commercial Projects: Large-scale commercial installations including hotel lobbies, shopping centers, and office buildings demand the productivity and consistency CNC bridge saws provide. Meet tight deadlines while maintaining quality standards.

Architectural Cladding: Building facades, feature walls, and architectural elements benefit from CNC precision. Complex patterns and varied dimensions execute reliably, enabling ambitious architectural visions.

Flooring and Tiling: Large-format tiles and custom flooring patterns cut efficiently with minimal waste. Precision ensures tiles fit together seamlessly with consistent grout lines.

Australian Market Advantages

Growing Renovation Market: Australia’s robust renovation industry drives demand for quality stone fabrication. Homeowners increasingly choose premium stone surfaces, creating opportunities for well-equipped fabricators.

Quality Standards: Australian consumers expect high-quality workmanship. CNC bridge saws help fabricators meet these expectations consistently, building reputation and customer loyalty.

Labor Efficiency: Australian labor costs make automation economically compelling. CNC bridge saws reduce the skilled labor required per project while improving output quality and consistency.

Material Costs: Stone materials represent significant investment. Minimizing waste through precise cutting directly impacts profitability. CNC accuracy optimizes material utilization, reducing scrap and maximizing yield from each slab.

Technical Specifications

IGOLDENCNC offers various bridge saw models suited to different workshop sizes and production volumes. Entry-level models feature 2-3 meter cutting lengths ideal for residential fabricators. Mid-range systems accommodate 3-4 meter slabs common in commercial work. Premium models handle oversized slabs and deliver maximum productivity for high-volume operations.

Cutting capacity typically ranges from 20mm to 150mm thickness, covering virtually all stone applications. Blade diameters from 350mm to 500mm balance cutting speed with blade life and cost considerations.

The IGOLDENCNC Australian Commitment

We’re committed to Australian stone fabrication industry success. Beyond selling equipment, we partner with fabricators for long-term prosperity, providing ongoing training, technical support, process optimization assistance, and industry insights.

Our growing Australian customer base demonstrates the trust fabricators place in IGOLDENCNC equipment and support.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.