Looking to invest in a reliable Stone CNC Machine for professional stone fabrication? Whether you need a 5 Axis Bridge Cutting Machine for complex countertop designs, 3D sculptures, and architectural stonework, or a versatile Stone Cutting Machine for efficient marble, granite, and quartz processing, the right equipment can transform your production. These machines are widely used for tombstone engraving, kitchen countertops, bathroom vanity tops, floor tiles, wall panels, and decorative stone art. Built with high-rigidity structures, powerful spindles, and advanced CAD/CAM compatibility, they ensure precision, durability, and long-term efficiency for workshops, stone factories, and custom art studios.

IGOLDENCNC Stone CNC Machines

A Stone CNC Machine is a computer-controlled system designed for high-precision stone cutting, marble cutting, granite cutting, and stone engraving on both natural and engineered materials, including granite, marble, quartz, sandstone, porcelain, and other hard stones. Equipped with robust 4-5 axis motion systems, diamond-tipped tools, and high-torque spindles (15-30kW), these machines perform cutting, engraving, milling, 3D carving, and polishing with tolerances of ≤0.1mm, ensuring professional-quality results for architecture, monuments, furniture, interior decoration, countertops, and signage projects. Applications range from kitchen countertops and facade cladding to artistic sculptures and tombstone engraving, with specialized models capable of machining ultra-hard stones like basalt or sintered stone. Built for industrial stone fabrication, workshops, and large-scale stone processing, these CNC machines combine precision, efficiency, and durability, providing a versatile solution for modern stone machining needs.

Summary Table: iGOLDENCNC Stone Machines

| Category | Primary Use | Typical Features |

|---|---|---|

| 5-Axis Bridge Saw | Advanced slab cutting & profiling | 5-axis motion, multi-angle cuts |

| 4+1 Axis Bridge Saw | Flexible stone cutting with rotation | Head rotates 360°, chamfering & hole cutting |

| CNC Granite Stone Engraving Machine | Engraving & lettering | Dual spindles, detailed engraving |

| CNC 3D Stone Carving Machine | Artistic & complex carving | Rotary spindle, 3D surface work |

| Stone CNC Router / Machining Center | General stone processing | Cutting, drilling, profiling |

Definition of Stone CNC Machine

A Stone CNC Machine is an automatic computer-controlled cutting solution designed for professional stone fabrication. It is widely used in workshops and factories to process granite, marble, quartz, slate, limestone, sandstone, travertine, jade, onyx, and engineered stones. These machines are capable of cutting, shaping, engraving, and polishing to create products such as kitchen countertops, bathroom vanity tops, floor tiles, wall cladding, tombstones, and sculptures.

What Is a Stone CNC Machine?

A Stone CNC Machine is an advanced computer-controlled cutting system designed for professional stone fabrication, combining high-precision capabilities with versatile production efficiency. It can handle complex multi-angle cutting, 3D shaping, edge profiling, straight cutting, slab trimming, and engraving in a single setup. Equipped with high-power spindles, diamond tools, and water-cooling systems, it ensures clean, smooth, and accurate processing of granite, marble, quartz, slate, limestone, sandstone, travertine, jade, onyx, and engineered stones. This makes it ideal for creating kitchen countertops, bathroom vanity tops, floor tiles, wall panels, tombstones, sculptures, and decorative stonework, meeting the needs of both industrial stone fabrication and custom artistic projects.

How Stone CNC Machines Work?

Stone CNC Machines integrate CAD/CAM software with computer numerical control to execute precise cutting and shaping according to digital designs. The workflow typically includes:

1. Design Preparation – Create 2D or 3D models using CAD software.

2. CAM Programming – Generate toolpaths and define cutting parameters.

3. Machine Setup – Secure slabs on the working table, install diamond blades or other tools.

4. Automatic Processing – The CNC system controls spindles, rotary axes, and cooling systems to perform cutting, carving, and engraving with minimal manual intervention.

5. Finishing & Polishing – Edge polishing, surface smoothing, or 3D detailing is completed as required.

Built with high-rigidity steel frames, powerful spindles, dual rotary axes, and bidirectional water-cooling systems, these machines deliver precision, stability, and long-term durability. By combining the capabilities of a 5 Axis Bridge Cutting Machine for complex multi-angle operations and a Stone Cutting Machine for efficient slab processing, workshops and factories can achieve ≤0.1mm tolerances, reduced material waste, and faster production cycles, making them ideal for modern stone fabrication and custom artistic applications.

Applications of Stone CNC Machines

• Stone Industry

Ideal for granite, marble, quartz, slate, sandstone, travertine, limestone, alabaster, basalt, jade, onyx, and artificial stones, these machines are widely used in tombstone and headstone fabrication, cemetery memorials, monuments, and architectural stone elements.

• Kitchen & Bathroom

Used for creating custom kitchen countertops, bathroom vanity tops, artificial quartz and marble surfaces, ceramic tiles, and decorative stone panels. Perfect for both small workshops and large-scale fabrication factories.

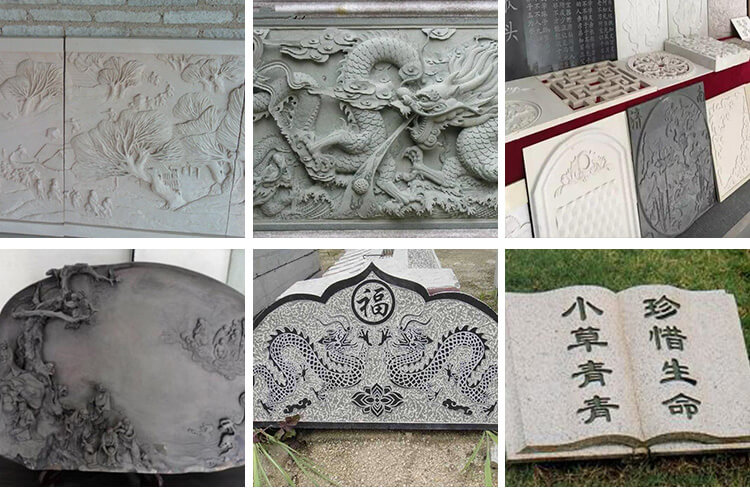

• Decorations & Art

Produce stone crafts, sculptures, gifts, jewelry, wall decorations, building ornaments, portraits, Buddha statues, and artistic reliefs. The 5 axis capability enables complex 3D carving and intricate designs.

• Construction & Interior

Fabricate floor tiles, wall panels, facades, cladding, and interior decorative elements with high precision and efficiency.

• Advertising & Signage

Manufacture billboards, company signs, logos, emblems, display panels, and 3D characters using precise cutting and engraving techniques.

• Custom Projects & Industrial Applications

Suitable for large slabs, customized architectural projects, and industrial stone production, ensuring accurate cuts, minimal waste, and consistent quality across different stone materials.

How To Use a Stone CNC Machine?

Proper and accurate operation of a Stone CNC Machine ensures high-quality results, whether for complex 3D shaping with a 5 Axis Bridge Cutting Machine or efficient slab cutting with a Stone Cutting Machine. Follow these steps to maximize efficiency and precision:

Step 1. Machine Connection and Power-On

Before starting, ensure the machine is properly connected to the computer and power supply. Turn on the machine and computer, launch the control software, and enter the operating system.

Step 2. Set the Origin Coordinates

Use the software menu to return the machine to its origin. This calibrates the X/Y/Z axes and ensures accurate positioning for all subsequent operations.

Step 3. Load the Processing Program

Open the desired CAD/CAM file in the control software. Select the correct drive, folder, and file name, then load the program into the system. Verify the toolpath and settings before execution.

Step 4. Determine the Workpiece Origin

Manually position the workpiece on the machine table. Adjust the X and Y axes to align with the predetermined reference point. Set this point as the workpiece origin in the software to ensure all cuts and carvings start from the correct location.

Step 5. Tool Setup and Safety Check

Install the appropriate diamond blades, router bits, or engraving tools. Ensure the water-cooling system or bidirectional cooling is functional. Verify clamps, fixtures, and safety guards are secure.

Step 6. Start Machining

Execute the loaded program. Monitor the machine during cutting, carving, or engraving. Ensure spindle speed, feed rate, and cooling systems operate correctly. Pause immediately if any abnormal noise, vibration, or error occurs.

Step 7. Finishing and Inspection

Once machining is complete, remove the workpiece carefully. Inspect for precision, surface finish, and tool marks. Perform polishing, edge finishing, or secondary operations as required.

Advanced Stone CNC Machines for Precision Machining

Modern Stone CNC Machines provide technological advancements for precision stone processing. Both 5 Axis Bridge Cutting Machines and Stone Cutting Machines are compatible with major CAD/CAM software, enabling accurate and efficient machining of granite, marble, quartz, and other natural or artificial stones.

Key Features of Advanced Stone CNC Machines:

• Three-Dimensional Machining: Perform complex 3D shaping, edge profiling, and curved cuts in a single setup.

• Multi-Axis Motion Control: 5 axis movement allows multi-angle processing and intricate designs without repositioning the workpiece.

• Specialized Cutting Tools: Equipped with diamond blades, high-power spindles, and bidirectional cooling systems for durability and precision.

• Versatile Applications: Ideal for kitchen countertops, bathroom vanity tops, tombstones, sculptures, decorative stone panels, and architectural elements.

• High Precision Machining: Ensures tight tolerances, clean edges, and consistent quality across all types of stone.

Buyer’s Guide for Stone CNC Machines

Buying a Stone CNC Machine can significantly improve productivity and precision in stone fabrication, whether for complex 3D shaping with a 5 Axis Bridge Cutting Machine or efficient slab cutting with a Stone Cutting Machine. To select the right machine, consider the following key factors:

• Specific Application Requirements: Determine whether your production focuses on countertops, tombstones, sculptures, or decorative panels.

• Material Properties: Consider granite, marble, quartz, slate, or other natural and artificial stones.

• Desired Machining Capabilities: Edge profiling, 3D carving, slab trimming, or multi-angle processing.

• Budget Constraints: Factor in the cost of the machine, tooling, installation, and maintenance.

Step 1. Consultation

Inform your supplier of your requirements, including the stone type, maximum slab size (Length × Width × Thickness), and expected production volume.

Step 2. Quotation

Receive a detailed quotation based on your needs, including specifications, tooling, optional accessories, and pricing.

Step 3. Process Evaluation

Both parties review technical parameters, delivery terms, and any customization requirements to ensure clarity and avoid misunderstandings.

Step 4. Order Placement

Confirm the order by signing the Proforma Invoice (PI) or sales contract after reviewing all details.

Step 5. Production

Your machine will enter production immediately upon confirmation and deposit payment. Updates on progress are provided throughout manufacturing.

Step 6. Quality Control

Every Stone CNC Machine undergoes strict inspection and testing before leaving the factory to ensure precision, stability, and performance.

Step 7. Delivery

Machines are shipped according to agreed terms, with all necessary packaging to protect equipment during transit.

Step 8. Customs Clearance

All required documentation is provided to ensure smooth import/export processes.

Step 9. Support and Service

Comprehensive technical support is available via Phone, Email, WhatsApp, Online Chat, or Remote Service. Some regions also offer door-to-door support.

Precautions for Using Stone CNC Machines

To ensure safety, machine longevity, and high-quality stone processing, follow these precautions when operating a Stone CNC Machine:

• Check Lubrication and Safety Devices: Before use, confirm all moving parts are properly lubricated and that protection devices meet operational requirements.

• Monitor for Loose Components: During operation, inspect accessories and fixtures for any signs of looseness. Stop the machine immediately if detected to prevent damage and material waste.

• Maintain Safe Operating Environment: Ensure the surrounding area is clear of obstacles, especially when the machine operates at high speeds.

Respond to Abnormal Noise: Immediately halt the machine if unusual noise occurs and check for the cause before resuming work.

• Proper Tool and Workpiece Handling: Do not place tools or materials on the machine table while operating. Avoid touching any rotating parts during machining.

• Post-Operation Cleaning: After completing a job, clean the machine thoroughly, remove debris, and disconnect the power supply.

• Stone Carving Tips: Relief carving usually requires higher spindle power. For hard stones, repeated passes may lighten darker engraving results. Clean oily residue or stone dust promptly with a damp cloth to maintain surface quality.

• Layered Cutting for Thick Stone: When cutting very thick stone, reduce cutting speed and cut in multiple layers to avoid tool breakage. Repeated shallow cuts help ensure smooth and safe processing.

Common Materials and Considerations:

Granite – The hardest natural stone requiring powerful spindles (15-22kW), premium diamond tooling, and robust machine construction. IGOLDENCNC bridge saws designed for granite feature reinforced structures handling cutting forces without deflection.

Marble – Softer than granite but prone to chipping if cut improperly. IGOLDENCNC machines incorporate variable speed control and optimized water delivery preventing chip-out on delicate marbles.

Quartzite – Natural quartzite rivals granite in hardness while engineered quartz (Caesarstone, Silestone) requires special attention to heat management. IGOLDENCNC’s high-volume cooling systems prevent the discoloration and cracking that plague inadequately cooled quartz cutting.

Porcelain Slabs – Large-format porcelain demands specialized tooling and cutting parameters. IGOLDENCNC equipment accommodates the growing porcelain market through adjustable cutting speeds and diamond tooling optimized for this challenging material.

Exotic Materials – Semi-precious stones, ultra-compact surfaces (Dekton, Neolith), and recycled glass materials each present unique challenges. IGOLDENCNC’s programmable cutting parameters adapt to virtually any material entering the stone industry.

Document your material mix percentages to ensure selected equipment handles your full range of products efficiently. IGOLDENCNC can recommend specific configurations optimized for your material profile.

Job Complexity and Features

Modern stone installations increasingly demand complex features that simple cutting cannot accommodate. IGOLDENCNC offers comprehensive solutions addressing diverse fabrication requirements.

Mitered Edges and Waterfall Islands – The explosive popularity of waterfall edges requires precision 45-degree cutting. IGOLDENCNC bridge saws with CNC-controlled blade tilting deliver perfect miters consistently, enabling fabricators to confidently pursue this lucrative market segment.

Edge Profiling – Bullnose, ogee, beveled, and custom edge profiles add value and aesthetic appeal. IGOLDENCNC machines integrate edge profiling capabilities through programmable edge routing or diamond profile wheels, completing countertops in single setups.

Sink and Cooktop Cutouts – Precise cutouts for undermount sinks, cooktops, and fixtures are standard requirements. IGOLDENCNC CNC control enables automatic cutout generation from simple dimensional inputs, eliminating tedious manual layout.

Decorative Elements – Inlays, custom patterns, and artistic designs differentiate premium fabricators. IGOLDENCNC’s versatile CNC capabilities execute intricate designs that manual methods cannot achieve.

Evaluate your job mix to determine which features add most value to your business. IGOLDENCNC equipment can be configured with capabilities matching your specific needs without paying for unnecessary features.

Conclusion: Investing in IGOLDENCNC Technology for 2026 Success

Purchasing stone CNC equipment in 2026 requires careful evaluation of technology, capabilities, costs, and support infrastructure. IGOLDENCNC offers comprehensive solutions addressing the diverse needs of modern stone fabricators, from small custom shops to large production facilities.

The key to successful equipment investment lies in thoroughly understanding your business requirements, carefully evaluating options against objective criteria, and selecting equipment that positions your operation for sustainable growth. IGOLDENCNC’s combination of proven technology, ongoing innovation, comprehensive support, and competitive pricing makes it a compelling choice for fabricators seeking reliable, productive stone processing equipment.

As the stone fabrication industry continues evolving, equipment that adapts to changing demands provides lasting value. IGOLDENCNC’s commitment to continuous improvement, customer support, and technology advancement ensures that 2026 equipment purchases remain productive investments throughout their 15-20 year service lives.

Whether expanding existing operations, replacing aging equipment, or establishing new fabrication businesses, IGOLDENCNC stone CNC machines deliver the precision, productivity, and reliability essential for success in today’s competitive stone fabrication marketplace.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.