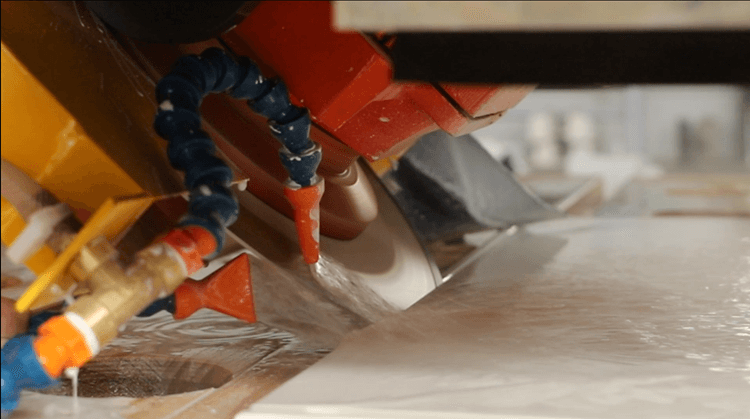

Mitered edges represent one of the most sophisticated and visually striking details in modern stone countertop fabrication. These precisely angled joints create seamless corners, waterfall edges, and elegant transitions that elevate ordinary countertops into architectural masterpieces. However, achieving perfect mitered edges demands exceptional precision, specialized equipment, and advanced cutting technology that only professional CNC bridge saws can deliver.

Stone mitered edge cutting

IGOLDENCNC has emerged as a leading innovator in CNC stone cutting technology, offering bridge saw systems specifically engineered to produce flawless mitered edges with repeatable accuracy. Their advanced machines combine robust construction, intelligent control systems, and precision cutting capabilities that transform complex mitered edge production from a challenging specialty process into a reliable, efficient operation accessible to stone fabricators at all levels.

Whether for luxury kitchens, hotel lobbies, commercial spaces, or architectural facades, clients increasingly demand seamless stone joints, sharp edges, and flawless finishing. One of the most critical processes to achieve this standard is mitered edge cutting, especially 45-degree stone edge cutting.

What Is a CNC Stone Mitered Edge Cutting Machine?

A CNC stone mitered edge cutting machine uses computer numerical control technology to automate the cutting process. By integrating precision motors, servo drives, and intelligent software, the machine ensures accurate angle control, smooth cutting paths, and repeatable results.

Key Capabilities

-

Precise 45° (or adjustable angle) cutting

-

Automatic tool positioning

-

High-speed and stable cutting performance

-

Support for complex shapes and long slabs

-

Reduced operator error

Among various CNC solutions, bridge saw machines are the most commonly used for mitered edge cutting in stone fabrication.

What Is Mitered Edge Cutting in Stone Processing?

Understanding Mitered Edges

A mitered edge is created by cutting two stone slabs at matching angles (commonly 45°) so they join seamlessly at the corner. When bonded together, the joint appears as a solid, thick slab without visible seams.

This technique is widely used in:

-

Kitchen countertops

-

Waterfall islands

-

Bathroom vanities

-

Stone stairs and risers

-

Window sills and wall cladding

-

Luxury furniture and architectural elements

Compared to traditional straight-edge joints, mitered edges provide:

-

A cleaner, more luxurious appearance

-

The illusion of thicker stone slabs

-

Better alignment and structural integrity

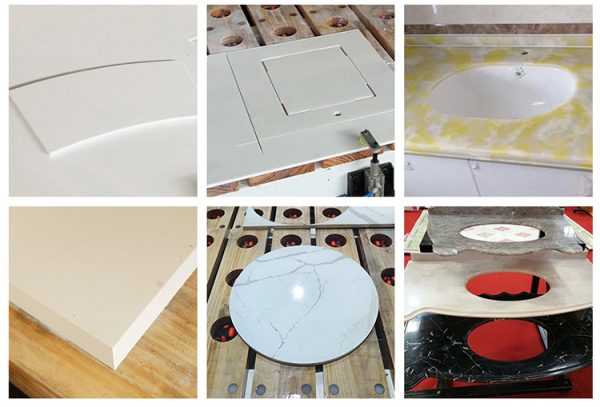

Understanding Mitered Edge Applications

Kitchen Countertops

Perfect 45° edges for waterfall islands and seamless joints.

Bathroom Vanity Tops

Elegant, thick-edge appearance with clean corner joints.

Staircases and Steps

Accurate miter cuts for risers and treads enhance safety and aesthetics.

Wall Cladding and Facades

Precise angle cuts ensure tight joints and uniform surfaces.

Custom Stone Furniture

Tables, shelves, and decorative elements benefit from seamless miter joints.

Kitchen Countertop Waterfall Edges

Waterfall edges, where countertop material cascades vertically down the side of cabinetry to the floor, have become increasingly popular in contemporary kitchen design. These dramatic features require precise 45-degree miters where the horizontal surface meets the vertical panel. Any gap or misalignment becomes immediately visible and detracts from the premium appearance that waterfall edges should provide.

IGOLDENCNC bridge saws cut both mating surfaces with identical 45-degree angles, ensuring perfect fit when assembled. The CNC precision maintains consistent angles across the entire cut length, eliminating the waviness and angle variations common in manual cutting. Fabricators report virtually zero fitting issues when using IGOLDENCNC mitered edge cutting capabilities.

Island and Peninsula Corners

L-shaped and U-shaped countertop configurations require mitered corners where sections meet at 90 degrees. These visible joints must align perfectly to maintain the illusion of a single continuous stone piece. Traditional butt joints with visible seams diminish the aesthetic quality, while properly executed miters create the seamless appearance that homeowners and designers demand.

IGOLDENCNC systems cut matching miters for both connecting pieces simultaneously or sequentially with perfect angle consistency. The automated process ensures that left and right miter cuts are mirror images, guaranteeing alignment during installation.

Architectural Applications

Beyond residential countertops, mitered edges appear in commercial reception desks, hotel vanities, restaurant bar tops, and architectural wall cladding. These high-visibility applications demand flawless execution where even minor imperfections become magnified. IGOLDENCNC’s precision mitering capabilities enable fabricators to confidently bid on and execute premium commercial projects.

Decorative Edge Profiles with Miters

Some advanced applications combine mitered joints with decorative edge profiles, creating complex geometries that showcase both technical capability and artistic design. IGOLDENCNC bridge saws execute these sophisticated cuts through integrated edge profiling and mitering in coordinated sequences, producing results impossible through manual methods.

Limitations of Traditional Stone Miter Cutting Methods

Before CNC automation, stone miter cutting relied heavily on manual tools or semi-automatic machines. These methods present several challenges:

1. Inconsistent Cutting Angles

Manual angle adjustment often leads to deviations from the exact 45°, causing visible gaps during assembly.

2. High Material Waste

Even a small error in angle or depth can ruin an entire slab, especially expensive marble or quartz.

3. Low Efficiency

Manual processes are time-consuming and labor-intensive, limiting production capacity.

4. Dependence on Skilled Labor

Highly experienced operators are required, and results still vary from person to person.

5. Poor Repeatability

Mass production of identical stone components is nearly impossible with traditional tools.

These limitations make traditional methods unsuitable for modern stone factories aiming for precision, scalability, and consistent quality.

Technical Specifications and Capabilities

| Technical indicators | parameter |

| Model | iGS-B3620(Pro) |

| Stroke of X axis | 3600mm |

| Stroke of Y axis | 2000mm |

| Z-axis stroke 1 | 255mm(Blade Diameter 400mm) |

| A axis | 0-90° |

| C axis | 360° |

| Saw blade motor power | 15kw/18.5kw/22kw |

| Spindle | HQD 6KW air-cooled spindle |

| Blade Diameter | 350-500mm |

| Input power | 3-phase AC 380V/220V 50-60Hz 10A |

| Body | Heavy duty bed |

| Gantry | Steel structure |

| Table | Automatic copy flip feeding |

| Guide rail | Taiwan HIWIN |

| Rack | Taiwan YYC |

| Screw | Taiwan TBI screw 5010 |

| Motor | IGOLDENCNC |

| System | IGOLDENCNC |

| Water pump | Standard |

| Standard configuration function | Table flip, cross red light positioning, tool setting instrument, dial indicator, tool hanging, table cleaning, working camera、Pressing |

| Optional Functions | Pressing, suction cup displacement, photo layout, probe, dust-free installation measurement software |

Key Features of iGOLDENCNC Bridge Saw for Miter Cutting

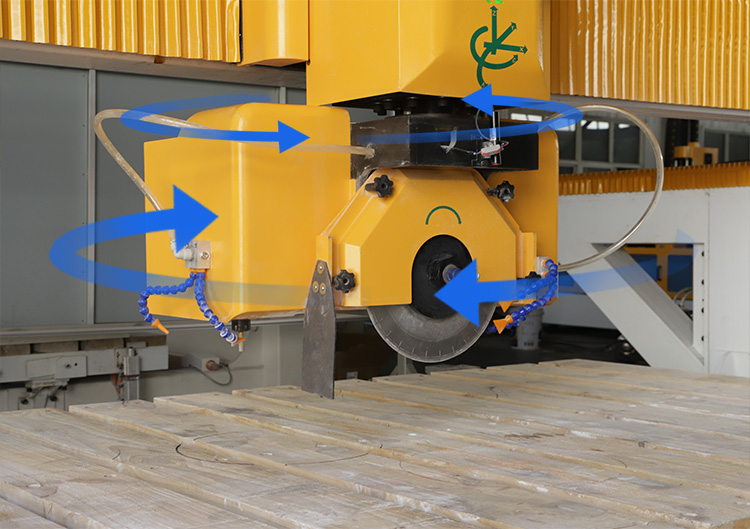

1. High-Precision 45° Tilting Cutting Head

The machine is equipped with a CNC-controlled tilting head, allowing:

-

Accurate 45° miter cuts

-

Smooth angle transitions

-

Consistent edge quality across long slabs

Angle adjustment is controlled digitally, eliminating human error.

2. Heavy-Duty Bridge Structure for Stability

The reinforced bridge design ensures:

-

Minimal vibration during cutting

-

Stable blade movement

-

Superior surface finish on mitered edges

This is especially important when cutting hard materials like granite or quartz.

3. Intelligent CNC Control System

The iGOLDENCNC Bridge Saw features an advanced CNC system that allows operators to:

-

Program cutting paths easily

-

Save and repeat miter cutting programs

-

Monitor cutting speed and depth in real time

Even less experienced operators can achieve professional results.

4. Compatibility with Multiple Stone Materials

This CNC stone mitered edge cutting machine can process:

-

Granite

-

Marble

-

Quartz

-

Artificial stone

-

Sintered stone

-

Limestone

One machine can serve multiple production needs, maximizing ROI.

5. Automatic Tool Movement and Positioning

The CNC system ensures:

-

Accurate blade positioning

-

Consistent cutting depth

-

Reduced setup time

This greatly improves production efficiency.

Frequently Asked Questions (FAQ)

1. What is a CNC stone mitered edge cutting machine?

A CNC stone mitered edge cutting machine is a computer-controlled stone cutting solution designed to create precise angled edges, typically at 45 degrees. It is widely used for producing seamless stone joints in countertops, waterfall islands, stairs, and architectural stone elements. Compared with manual cutting, CNC machines deliver higher accuracy, repeatability, and efficiency.

2. Can a CNC bridge saw be used for mitered edge cutting?

Yes. A CNC bridge saw is one of the most effective machines for stone mitered edge cutting. With a tilting cutting head and CNC-controlled axes, a bridge saw can accurately cut 45° or other customized angles. The iGOLDENCNC Bridge Saw is specifically designed to perform high-precision miter cutting on granite, marble, quartz, and sintered stone.

3. Why is 45-degree miter cutting important in stone fabrication?

45-degree miter cutting allows two stone pieces to join seamlessly at corners, creating the appearance of a thicker, solid slab. This technique is essential for high-end applications such as waterfall countertops, luxury bathroom vanities, and modern architectural designs where aesthetics and precision are critical.

4. What materials can the iGOLDENCNC Bridge Saw cut?

The iGOLDENCNC Bridge Saw supports a wide range of stone materials, including:

-

Granite

-

Marble

-

Quartz

-

Artificial stone

-

Sintered stone

-

Limestone

This versatility makes it an ideal CNC stone mitered edge cutting machine for both small workshops and large stone factories.

5. How accurate is the miter cutting on an iGOLDENCNC Bridge Saw?

Thanks to its CNC-controlled tilting head and rigid bridge structure, the iGOLDENCNC Bridge Saw can achieve highly accurate angle cuts with minimal deviation. This ensures tight joints, smooth edges, and consistent results even in long or batch production runs.

6. Is a CNC bridge saw difficult to operate for beginners?

No. Modern CNC bridge saws, including iGOLDENCNC models, are equipped with user-friendly control systems. Operators can easily set cutting angles, save programs, and repeat cutting tasks. Even operators with limited experience can quickly learn to perform professional miter cutting with proper training.

7. How does a CNC stone mitered edge cutting machine improve production efficiency?

A CNC machine automates angle adjustment, tool movement, and cutting paths, which:

-

Reduces setup time

-

Minimizes material waste

-

Increases cutting speed

-

Ensures consistent quality

This significantly boosts overall productivity compared to manual or semi-automatic cutting methods.

8. Can the iGOLDENCNC Bridge Saw handle custom angle cutting?

Yes. In addition to standard 45-degree miter cuts, the iGOLDENCNC Bridge Saw can be programmed to cut custom angles based on specific project requirements. This flexibility is especially useful for architectural stone and customized design applications.

9. Is investing in a CNC bridge saw worth it for small stone workshops?

Absolutely. While the initial investment is higher than manual equipment, a CNC bridge saw quickly pays for itself through reduced labor costs, lower material waste, higher efficiency, and improved product quality. Many small and medium-sized stone workshops use iGOLDENCNC Bridge Saws to upgrade their production capabilities and compete in high-end markets.

10. Why choose iGOLDENCNC for a CNC stone mitered edge cutting machine?

iGOLDENCNC offers:

-

Professional CNC stone machinery expertise

-

Reliable and durable bridge saw designs

-

Customizable machine configurations

-

Comprehensive technical support and after-sales service

These advantages make iGOLDENCNC a trusted choice for stone fabricators worldwide.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.