Understanding CNC Machining Centers

A CNC (Computer Numerical Control) machining center is a sophisticated automated machine tool capable of performing multiple machining operations on a workpiece in a single setup. Unlike traditional manual machines that require operator intervention for each operation, CNC machining centers execute complex sequences of cutting, drilling, milling, and boring operations automatically based on programmed instructions.

These versatile machines represent the pinnacle of modern manufacturing technology, combining precision, speed, and flexibility to produce everything from simple brackets to complex aerospace components. The integration of computer control with mechanical precision has revolutionized manufacturing across virtually every industry.

Key Components of a CNC Machining Center

Control System

The CNC controller is the machine’s brain, interpreting G-code programs and converting them into precise machine movements. Modern controllers feature intuitive graphical interfaces, simulation capabilities, and advanced features like adaptive feed control and tool life management. Popular control systems include Fanuc, Siemens, Haas, and Heidenhain.

Spindle Assembly

The spindle holds and rotates cutting tools at speeds ranging from 50 to over 40,000 RPM depending on the machine type. High-performance spindles provide the power and speed necessary for efficient material removal while maintaining precision. Spindle motors typically range from 7.5 to 30+ horsepower for standard machining centers.

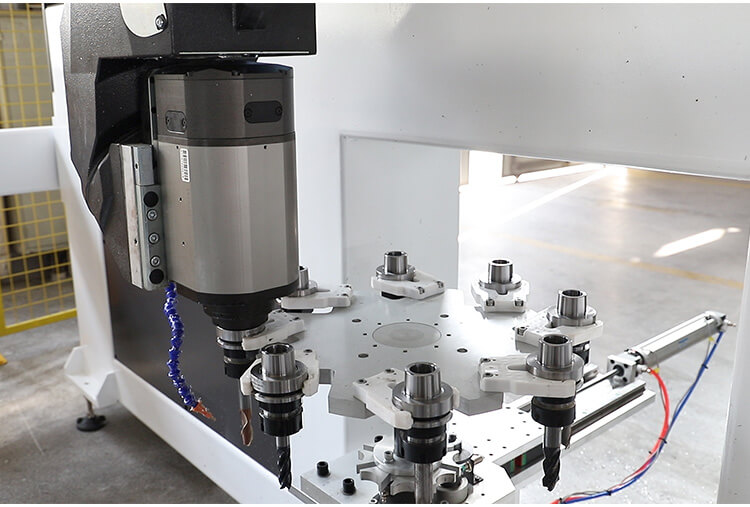

Automatic Tool Changer (ATC)

One of the defining features of machining centers is the automatic tool changer, which stores multiple cutting tools in a magazine or carousel and automatically swaps tools during operation. This eliminates manual tool changes, reducing cycle times and enabling lights-out manufacturing. Tool magazines typically hold 20 to 120 tools, with some high-production systems accommodating 300+ tools.

Multi-Axis Motion System

CNC machining centers typically operate on three primary axes (X, Y, Z), with advanced models incorporating fourth and fifth axes for rotational movement. This multi-axis capability enables machining of complex geometries and undercuts without repositioning the workpiece. Precision ball screws, linear guides, and servo motors ensure accurate positioning with repeatability measured in microns.

Work Table and Fixturing

The work table provides a stable platform for securing workpieces. Tables may feature T-slots for clamping, integrated pallet changers for automated part loading, or hydraulic fixtures for rapid setup. Pallet systems enable operators to prepare the next job while the machine continues running, maximizing productivity.

2. Advantages of Using CNC Machining Center

When I first transitioned from manual machining to a CNC machining center, I wasn’t convinced it was the right move. Would it really be faster? Would it improve my quality? Would it be worth the investment?

It didn’t take long to see the difference. Suddenly, jobs that used to take days were completed in hours. Parts were more precise, and I could take on more work without increasing labor. If you’re considering a CNC machining center, here’s why it might be the best decision for your business.

Precision and Consistency

One of the biggest advantages of CNC machining centers is their ability to produce identical parts with extreme accuracy.

- High Precision: CNC machining centers can achieve tolerances as tight as ±0.001 inches, eliminating human error.

- Consistent Quality: Every part produced matches the last, no matter how many are made.

- Advanced Programming: Pre-set software controls the entire process, reducing manual adjustments.

Have you ever scrapped a batch of parts because of small inconsistencies? With CNC machining, that problem disappears.

Versatility in Machining Operations

A CNC machining center can handle multiple machining tasks, replacing several standalone machines.

- Milling, Drilling, and Tapping: All in one setup.

- Multi-Material Capability: Works with metals, plastics, composites, and more.

- Customization: Can be programmed for different part designs with ease.

Need to switch from a metal part to a plastic one? No problem. Just load a new program, and the machine handles the rest.

Better Workflow and Less Downtime

Machine downtime costs businesses thousands of dollars. CNC machining centers minimize interruptions.

- Automated Operations: No waiting for manual adjustments.

- Predictable Maintenance: Routine servicing prevents unexpected failures.

- Quick Setup Changes: Load a new program and start machining right away.

How much time do you lose setting up jobs manually? CNC machining centers streamline the process, keeping production moving.

Is a CNC Machining Center Right for You?

If you’re in manufacturing, metal fabrication, or custom machining, a CNC machining center can improve your production. But is it the right investment for your business?

- Do you handle high-volume production?

- Are you struggling with inconsistent quality or slow turnaround times?

- Would automation help you take on bigger or more complex jobs?

If you answered yes to any of these, then a CNC machining center might be the solution. And if you are looking for the best supplier, choose Blue Elephant. We tailor machines to your specifications and offer sample testing.

Types of CNC Machining Centers

Vertical Machining Centers (VMC)

Vertical machining centers feature a vertically oriented spindle positioned above the workpiece. This configuration offers excellent chip evacuation, easier tool access, and simpler setup procedures. VMCs are ideal for flat parts, mold making, and general manufacturing applications. They typically have smaller footprints than horizontal machines, making them popular in job shops.

Horizontal Machining Centers (HMC)

Horizontal machining centers position the spindle horizontally, allowing gravity to assist chip removal and providing better access to multiple sides of the workpiece. HMCs excel at high-volume production runs and heavy cutting operations. Many HMCs incorporate pallet changers for continuous operation and can machine four sides of a part in one setup.

Five-Axis Machining Centers

Five-axis machines add rotational capabilities (A and B axes) to the standard three linear axes, enabling complete part machining without manual repositioning. These sophisticated machines produce complex aerospace components, medical implants, and turbine blades with exceptional efficiency. Five-axis technology reduces setup time, improves surface finish, and enables previously impossible geometries.

Materials and Applications

CNC machining centers process virtually any machinable material including aluminum, steel, stainless steel, titanium, brass, copper, plastics, and composite materials. Each material requires specific cutting parameters, tooling, and coolant strategies for optimal results.

Aerospace Industry – Precision aircraft components, engine parts, and structural elements demand the accuracy and repeatability that CNC machining centers provide. Titanium and aluminum aerospace parts often require five-axis capabilities for complex contours.

Medical Device Manufacturing – Surgical instruments, orthopedic implants, and diagnostic equipment components benefit from the micron-level precision achievable with modern machining centers. Medical parts often require specialized materials like surgical-grade stainless steel and titanium alloys.

Automotive Production – Engine blocks, transmission housings, suspension components, and prototype parts rely heavily on CNC machining. High-production automotive facilities utilize horizontal machining centers with automated pallet systems for maximum throughput.

Mold and Die Making – Tool and die shops depend on machining centers for creating injection molds, stamping dies, and casting patterns. Complex 3D surfaces and tight tolerances make CNC technology essential for competitive mold manufacturing.

General Manufacturing – From industrial equipment to consumer products, CNC machining centers handle diverse production requirements with consistent quality and efficiency.

Advantages of CNC Machining Centers

Precision and Accuracy

Modern CNC machining centers maintain tolerances of ±0.0001 inches (±0.0025mm) or better, ensuring parts meet exact specifications consistently. This precision eliminates costly rework and reduces scrap rates significantly.

Increased Productivity

Automatic tool changing, rapid traverse speeds, and optimized toolpaths dramatically reduce cycle times. A single machining center often replaces multiple conventional machines while producing parts faster with fewer operators.

Flexibility and Versatility

Quick program changes enable machining centers to switch between different parts rapidly, making them ideal for both prototype development and production runs. The same machine that produces one complex part today can manufacture an entirely different component tomorrow.

Reduced Labor Costs

Automation reduces the skilled labor required for manufacturing. One operator can often supervise multiple CNC machining centers, and advanced systems enable unmanned night shifts for continuous production.

Improved Quality Control

Computer control eliminates human error in tool movement and ensures consistent dimensions across production runs. In-process probing systems verify part dimensions during machining, catching potential issues before parts are completed.

Programming and Operation

CNC machining centers use G-code programming language to control machine movements. Modern CAM (Computer-Aided Manufacturing) software generates G-code automatically from CAD models, dramatically simplifying programming. Operators can simulate complete machining operations virtually, identifying potential collisions or problems before cutting metal.

Conclusion

CNC machining centers represent a fundamental pillar of modern manufacturing, offering unmatched versatility, precision, and productivity. Whether producing single prototypes or thousands of production parts, these sophisticated machines deliver consistent quality while reducing costs and lead times. Understanding CNC machining center capabilities helps manufacturers make informed equipment investments and remain competitive in today’s demanding marketplace.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.