The global stone processing machine market has experienced significant growth and transformation in recent years, driven by increasing construction activities, infrastructure development, and rising demand for decorative stone applications. This comprehensive analysis examines the current market landscape, key trends, and future prospects for stone processing equipment.

Market Overview and Size

Global Market Valuation

The global stone processing machine market was valued at approximately $3.8 billion in 2024 and is projected to reach $5.2 billion by 2030, growing at a compound annual growth rate (CAGR) of 5.4% during the forecast period. This growth trajectory reflects the increasing demand for processed stone products across various end-use industries.

Regional Market Distribution

- Asia-Pacific: 45% market share (largest regional market)

- Europe: 28% market share

- North America: 18% market share

- Middle East & Africa: 6% market share

- Latin America: 3% market share

The Asia-Pacific region dominates the market due to rapid industrialization, urbanization, and significant construction activities in countries like China, India, and Southeast Asian nations.

Common machines include:

-

Stone polishing machines

-

Edge profiling machines

These machines are widely used in construction, monument making, interior design, and industrial stone fabrication.

Stone Cutting and Sawing Machines

Bridge Saws: Used for precise cutting of granite, marble, and other natural stones

- Market share: 35% of total stone processing equipment

- Applications: Countertops, flooring, architectural elements

- Price range: $50,000 – $500,000

Wire Saws: Employed for quarrying and large block cutting

- Growing at 6.2% CAGR

- Applications: Quarry operations, large-scale stone extraction

- Technological advancement: Diamond wire technology

Multi-blade Gang Saws: For producing multiple slabs simultaneously

- Efficiency improvements driving adoption

- Applications: Mass production of stone slabs

- Integration with automated handling systems

Polishing and Finishing Equipment

Calibrating Machines: For achieving uniform thickness and surface finish

- Market growth: 5.8% CAGR

- Applications: Tile production, architectural panels

- Technology trend: Automated thickness control

Polishing Lines: Complete systems for stone surface finishing

- Integration with quality control systems

- Applications: High-end architectural projects

- Customization for different stone types

Edge Processing Machines: For creating decorative edges and profiles

- Growing demand in residential applications

- Applications: Countertops, furniture, decorative elements

- CNC integration for complex profiles

Drilling and Boring Equipment

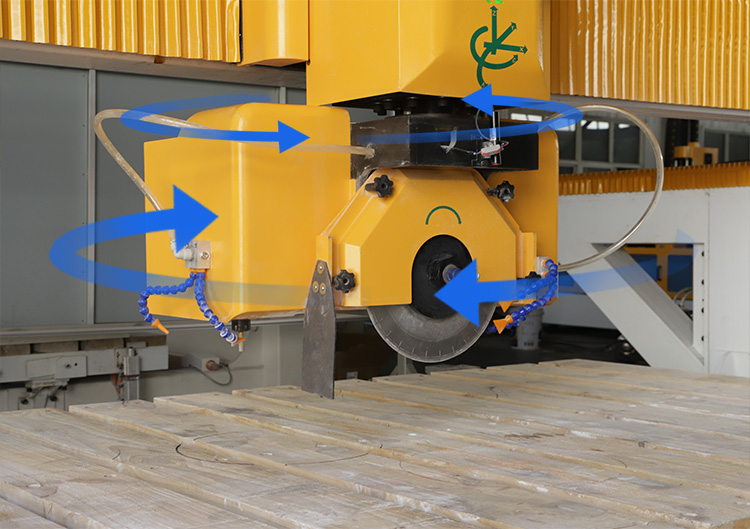

CNC Stone Machining Centers: Advanced multi-axis processing

- Fastest growing segment: 8.1% CAGR

- Applications: Complex architectural elements, artistic works

- Integration with CAD/CAM software

Core Drilling Machines: For creating holes and openings

- Applications: Plumbing installations, architectural features

- Portable and stationary variants available

Shaping and Engraving Systems

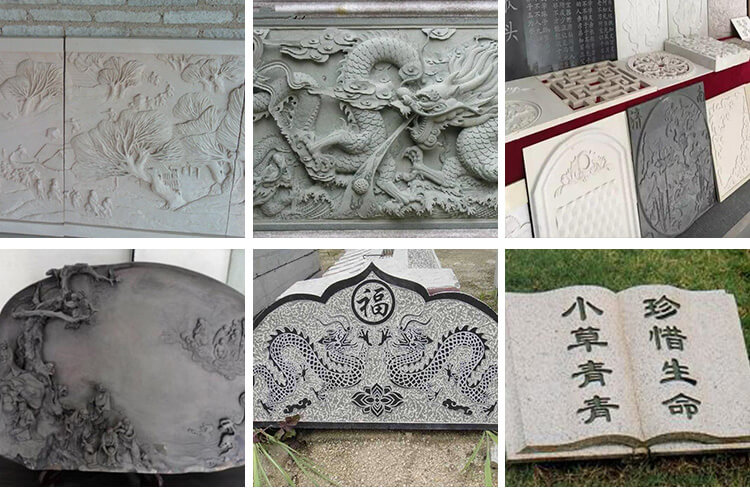

Stone Engraving Machines: For decorative and memorial applications

- Growing personalization trends

- Applications: Monuments, artistic works, signage

- Laser and mechanical engraving technologies

Market Applications

-

Construction & Architecture: Flooring, wall cladding, countertops, decorative panels

-

Monument & Tombstone Industry: Headstone engraving, memorials, statues

-

Interior & Furniture: Kitchen countertops, bathroom vanities, stone furniture

-

Landscape & Garden: Stone fountains, sculptures, balustrades, paving stones

-

Industrial Processing: Artificial quartz, ceramic tiles, engineered stones

Market Drivers

-

Growing Construction Industry: Demand for stone in commercial & residential projects

-

Rising Demand for Customization: CNC machines allow personalized engraving and cutting

-

Urbanization & Infrastructure Growth: Expanding use of natural stone in smart cities

-

Shift Toward Automation: Reducing labor cost with CNC and robotic systems

-

Export Opportunities: Asia-Pacific leading in stone exports (China, India, Turkey, etc.)

Market Challenges

-

High Initial Investment: CNC and waterjet machines require large capital

-

Skilled Labor Requirement: Operators need training in CAD/CAM and CNC

-

Competition from Artificial Materials: Quartz and ceramics competing with natural stone

-

Environmental Regulations: Dust, slurry, and water usage control

Regional Market Analysis

Asia-Pacific Market Dynamics

China: Largest consumer and producer

- Domestic market: $1.7 billion

- Export manufacturing base for global markets

- Government infrastructure investments driving demand

India: Rapidly growing market

- Traditional stone processing industry modernizing

- Increasing construction activities

- Growing granite and marble export industry

Southeast Asia: Emerging opportunities

- Infrastructure development projects

- Growing middle class driving residential construction

- Investment in tourism and hospitality sectors

European Market Characteristics

Italy: Technology and innovation hub

- Home to leading equipment manufacturers

- Strong domestic stone processing industry

- Export-oriented production

Germany: Engineering excellence

- Focus on precision and automation

- Strong industrial customer base

- Integration with Industry 4.0 concepts

Spain: Significant market presence

- Large natural stone industry

- Both domestic consumption and export markets

- Traditional craftsmanship meeting modern technology

North American Market Trends

United States: Mature but evolving market

- Focus on high-value applications

- Emphasis on automation and efficiency

- Growing engineered stone segment

Canada: Niche market opportunities

- Focus on architectural applications

- Strong granite processing industry

- Export-oriented production

Conclusion

The stone processing machine market presents significant opportunities driven by global construction growth, technological advancement, and increasing demand for processed stone products. While challenges exist in terms of economic volatility and environmental regulations, companies that invest in innovation, sustainability, and market expansion are well-positioned for success.

The market’s future will be shaped by automation, digitalization, and sustainability initiatives. Success will depend on companies’ ability to adapt to changing customer needs, regulatory requirements, and technological possibilities while maintaining competitive positioning in an increasingly global marketplace.

Key strategic considerations for market participants include investment in advanced technologies, expansion into emerging markets, development of sustainable solutions, and building comprehensive service capabilities to support customers throughout the equipment lifecycle.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.