If you’re considering investing in a wood CNC router in 2025, one of the first questions you’ll ask is: “How much does it cost?”

The short answer: Wood CNC router prices range from $2,000 to over $80,000 in 2025, depending on size, power, axis configuration, and features like automatic tool change (ATC).

This article will break down the cost of wood CNC routers by category, explain the factors that influence pricing, and help you choose the right machine for your budget and business needs.

Average Price Range of Wood CNC Routers in 2025

| CNC Router Type | Price Range (USD) | Suitable For |

|---|---|---|

| Entry-Level Hobby CNC Router | $2,000 – $5,000 | DIY users, small workshops |

| Small Professional CNC Router | $5,000 – $12,000 | Custom furniture, crafts, signs |

| Mid-Range CNC Router (3-Axis) | $12,000 – $25,000 | Small to medium factories |

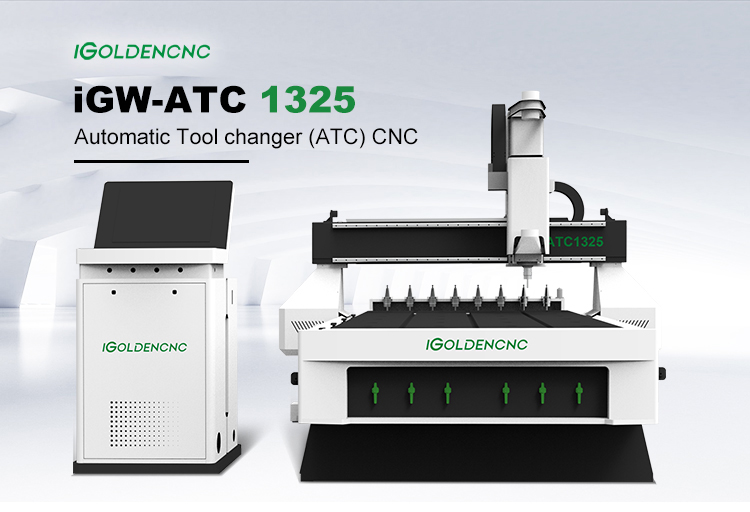

| ATC Wood CNC Router | $20,000 – $50,000 | High-volume woodworking shops |

| 4 Axis CNC Router | $25,000 – $60,000 | Complex 3D carving, mold making |

| 5 Axis CNC Router | $50,000 – $80,000+ | High-end furniture, musical instruments, aerospace woodwork |

| Industrial Large-Scale Router | $40,000 – $100,000+ | Mass production, big factories |

Factors That Affect Wood CNC Router Price

1. Machine Size and Work Area

-

Small routers (600×900mm) are cheaper.

-

Large routers (2000×4000mm+) are more expensive.

2. Axis Configuration

-

3-axis CNC routers → Most common and affordable.

-

4-axis CNC routers → Allow rotary carving and complex shapes.

-

5-axis CNC routers → Premium machines for advanced 3D processing.

3. Spindle Power

-

3kW–6kW → Suitable for basic woodworking.

-

9kW+ → Required for industrial heavy cutting.

4. Features & Automation

-

ATC (Automatic Tool Changer) adds $10,000–$20,000.

-

Vacuum table for holding workpieces adds cost.

-

Dust collection system may be included or separate.

5. Brand & Manufacturer

-

Local Chinese CNC brands (e.g., IGOLDENCNC) are more affordable.

-

European & US brands (e.g., Biesse, SCM) cost significantly more.

Entry-Level Desktop CNC Routers ($500 – $3,000)

Basic Hobby Machines ($500 – $1,500)

- Small working area (12″ x 12″ to 24″ x 24″)

- Single spindle, basic stepper motors

- Examples: iGW-ATC 1313, SainSmart 3018

- Suitable for: Small crafts, engraving, basic prototyping

Advanced Hobbyist Models ($1,500 – $3,000)

- Medium working area (24″ x 24″ to 36″ x 24″)

- Better spindles (500W-800W)

- Examples:iGW-MST

- Suitable for: Serious hobbyists, small business start-ups.

Mid-Range Professional CNC Routers ($3,000 – $25,000)

Small Professional Machines ($3,000 – $8,000)

- Working area: 2′ x 4′ to 4′ x 4′

- 1-2 HP spindles

- Examples: iGW-MST

- Suitable for: Small woodworking shops, custom furniture makers

Medium Professional Systems ($8,000 – $15,000)

- Working area: 4′ x 8′ standard

- 3-5 HP spindles

- Automatic tool changers (ATC)

- Examples: iG8–ATC

Advanced Professional Models ($15,000 – $25,000)

- 4′ x 8′ to 5′ x 10′ working areas

- 5-10 HP spindles

- Advanced features: vacuum tables, dust collection

Industrial CNC Routers ($25,000 – $200,000+)

Production Line Systems ($25,000 – $75,000)

- Large format (5′ x 12′ to 8′ x 16′)

- 10-15 HP spindles

- Multiple tool changers

- Automated material handling

High-End Industrial Systems ($75,000 – $200,000+)

- 5-axis capabilities

- Multiple spindles

- Automated loading/unloading

- Advanced software packages

Additional Costs to Consider

Software

- Basic CAM Software: $500 – $2,000

- Professional CAM Packages: $2,000 – $10,000

- Specialized Wood CAM: $3,000 – $15,000

Tooling and Accessories

- Starter Tool Set: $500 – $2,000

- Professional Tool Collection: $2,000 – $8,000

- Specialized Bits and Holders: $200 – $500 per tool

Installation and Setup

- Self-Installation: $0 (DIY)

- Professional Installation: $1,000 – $5,000

- Training and Support: $1,000 – $5,000

Dust Collection Systems

- Basic Shop Vacuum: $200 – $800

- Professional Dust Collection: $1,000 – $5,000

- Industrial Systems: $5,000 – $20,000

Conclusion

Wood CNC router costs in 2025 range from under $1,000 for basic hobby machines to over $200,000 for industrial production systems. The key is matching your budget to your actual needs:

- Hobbyists: $1,500 – $3,000 provides excellent capability

- Small Businesses: $8,000 – $20,000 offers professional features

- Production Shops: $25,000+ ensures industrial reliability

Remember to budget for additional costs including software, tooling, installation, and training, which can add 20-50% to the base machine cost. Consider financing options and look for package deals to maximize value.

The investment in a quality CNC router typically pays for itself through increased productivity, consistency, and capability to take on more complex projects. Choose based on your current needs with some room for growth, rather than buying the cheapest option that may quickly become limiting.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.