CNC bridge saw machines represent the pinnacle of precision cutting technology in the stone fabrication industry. These advanced automated cutting systems have revolutionized how manufacturers, contractors, and fabricators approach stone processing, delivering unmatched accuracy and efficiency for granite, marble, quartz, and ceramic tile cutting operations.

What is a CNC Bridge Saw Machine?

A CNC (Computer Numerical Control) bridge saw machine is a sophisticated cutting system that combines traditional bridge saw mechanics with computer-controlled precision. Unlike manual bridge saws, CNC versions use programmed instructions to execute cuts with millimeter-level accuracy, making them ideal for complex stone fabrication projects.

Key Components of CNC Bridge Saw Systems

Bridge Structure: The robust steel frame that spans across the cutting table, providing stability and support for the cutting head.

CNC Control System: Advanced software interface that allows operators to program cutting patterns, shapes, and dimensions with precision.

Diamond Cutting Blade: High-quality diamond-embedded blades designed for cutting various stone materials including granite, marble, limestone, and engineered stone.

Water Cooling System: Integrated cooling mechanism that reduces blade wear and eliminates dust during cutting operations.

Automatic Material Handling: Some models feature automated loading and unloading systems for increased productivity.

Advantages of CNC Bridge Saw Machines

Precision and Accuracy

CNC bridge saws deliver cutting accuracy within ±0.1mm, ensuring perfect fits for countertops, tiles, and architectural stone elements. This level of precision reduces material waste and eliminates the need for manual adjustments.

Increased Productivity

Automated cutting processes can operate continuously with minimal supervision, significantly increasing daily output compared to manual cutting methods. Many CNC bridge saws can complete complex cutting patterns in a fraction of the time required by traditional methods.

Versatility in Applications

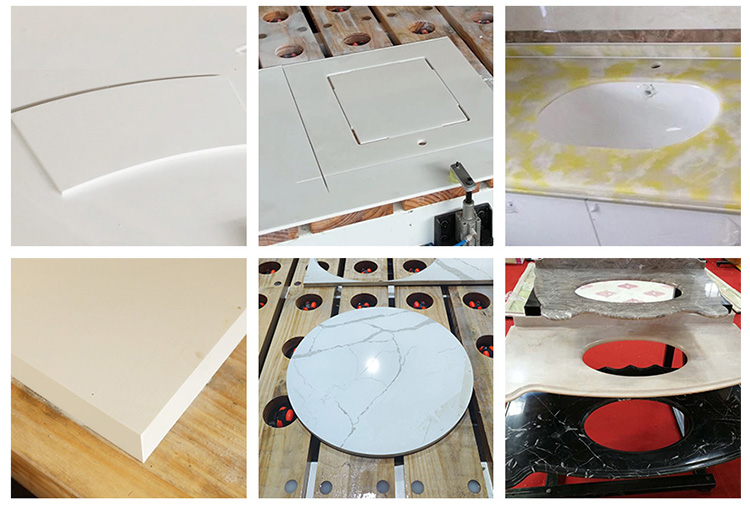

These machines excel at various cutting applications including:

- Kitchen and bathroom countertop fabrication

- Floor and wall tile cutting

- Architectural stone elements

- Monument and headstone production

- Custom decorative stone pieces

Cost-Effective Operation

While the initial investment is higher than manual saws, CNC bridge saws reduce labor costs, minimize material waste, and increase overall profitability through improved efficiency.

Types of CNC Bridge Saw Machines

Standard CNC Bridge Saws

Entry-level models perfect for small to medium fabrication shops, offering basic CNC functionality with reliable cutting performance.

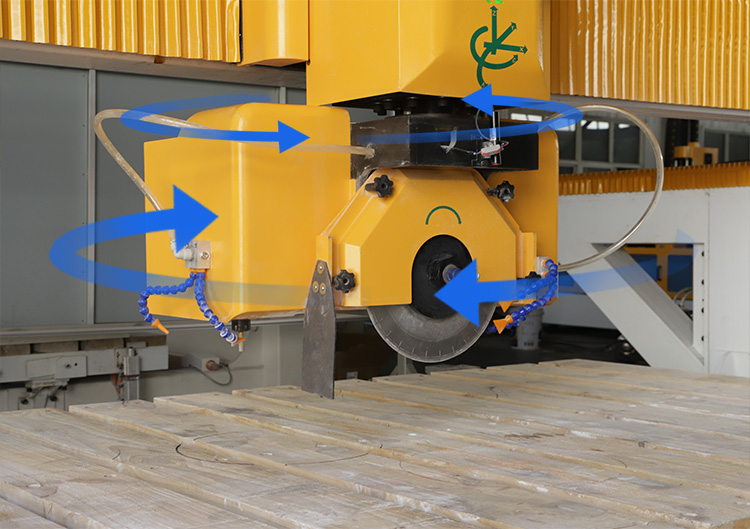

Multi-Axis CNC Bridge Saws

Advanced systems with 4-axis or 5-axis cutting capabilities, enabling complex three-dimensional cuts and beveled edges.

High-Production CNC Lines

Industrial-grade systems designed for large-scale operations, featuring automatic material handling, multiple cutting heads, and integration with other fabrication equipment.

Choosing the Right CNC Bridge Saw Machine

Consider Your Production Volume

Evaluate your daily cutting requirements to select a machine with appropriate cutting speed and table size.

Material Types and Thickness

Different machines handle various stone thicknesses and materials. Ensure your chosen model accommodates your primary materials.

Available Space and Infrastructure

Consider your facility’s power requirements, water supply, and physical space constraints.

Budget and ROI Considerations

Calculate the return on investment based on increased productivity, reduced labor costs, and improved cut quality.

Maintenance and Operating Best Practices

Regular Maintenance Schedule

- Daily blade inspection and cleaning

- Weekly lubrication of moving parts

- Monthly calibration checks

- Quarterly comprehensive system maintenance

Operator Training Importance

Proper training ensures safe operation, optimal cut quality, and maximum machine lifespan. Invest in comprehensive operator education programs.

Safety Protocols

CNC bridge saws require strict safety procedures including proper personal protective equipment, emergency shutdown procedures, and regular safety training updates.

Industry Applications and Market Trends

Growing Demand in Construction

The construction industry’s increasing demand for precision-cut stone materials drives CNC bridge saw adoption across residential and commercial projects.

Technological Advancements

Modern CNC systems integrate with CAD software, enabling direct file import and automated nesting for optimal material utilization.

Sustainable Manufacturing

Advanced cutting accuracy reduces material waste, supporting environmental sustainability goals in stone fabrication operations.

Conclusion

CNC bridge saw machines represent a smart investment for stone fabrication businesses seeking to improve cutting accuracy, increase productivity, and enhance profitability. As technology continues advancing, these systems become increasingly accessible to operations of all sizes.

Whether you’re a small fabrication shop looking to upgrade from manual cutting or a large manufacturer seeking to optimize production efficiency, CNC bridge saw technology offers scalable solutions that deliver measurable results.

For businesses ready to embrace precision cutting technology, CNC bridge saw machines provide the foundation for competitive advantage in today’s demanding stone fabrication market.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.