The company’s main products are: stone engraving machine, woodworking engraving machine, woodworking processing center, pneumatic tool change engraving machine, three-dimensional cylindrical engraving machine, laser engraving machine, multi-head furniture engraving machine, styrofoam foam engraving machine, engraving and milling machine, etc. Various types of computer numerical control engraving machine series products, and various special-shaped numerical control engraving equipment can be customized to realize customer’s personalized design.

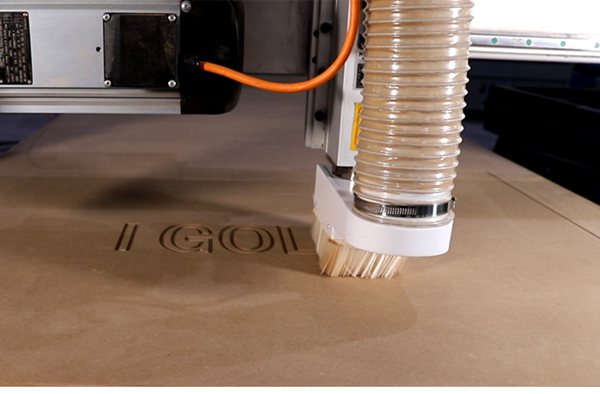

Professional panel furniture production line, woodworking CNC cutting machine manufacturer, straight-line tool change processing center.

Safety knowledge of woodworking CNC engraving machine

(1) The main causes of woodworking machinery accidents are as follows:

1. The rotating speed of the working knife shaft of the woodworking engraving machine is very high, the rotational inertia is large, and it is difficult to brake. In order to stop the motor as soon as possible after stopping, the operator is often used to using hands or

When a wooden stick is used to brake, injuries are often caused by accidentally contacting the hand with the rotating knife.

2. Woodworking machinery mostly uses manual feeding, which is the lurking cause of hand injury. When the hand pushes the wood to feed, it happens unconsciously due to knots, bends or other defects

Injury caused by hand contact with the cutting edge.

3. The high speed of woodworking engraving machine, coupled with uneven wood being processed, makes the noise and vibration large during the cutting process, and the labor intensity of workers is high and easy to fatigue. These factors are easy to make

The operator made mistakes and caused injury.

4. The operator is not familiar with the performance and safe operation technology of the woodworking engraving machine, or does not work in accordance with the safe operation rules, and the woodworking machinery and equipment are not installed with safety protection devices or safety

Failure of the full protection device can easily cause injury.

(2) The measures to prevent woodworking engraving machine accidents mainly include the following five aspects:

1. Pay attention to check the woodworking machinery and equipment should be equipped with effective braking devices, safety protection devices and dust suction and chip removal devices.

2. During the use of woodworking engraving equipment, it must be ensured that no harmful vibration will be generated when any tool is used at any cutting speed, so as to avoid danger during operation.

3. All exposed belt discs, turntables, rotating shafts, etc., should be protected and equipped with a protective cover.

4. The cutter shaft and electrical appliances should have interlocking devices to avoid accidentally touching the power button to rotate the cutter and cause injury when assembling, disassembling and replacing the cutter.

Frequently Asked Questions

- What are the most important safety precautions to take when using a woodworking CNC engraving machine?

- Always wear appropriate safety gear, such as goggles and ear protection, familiarize yourself with the machine’s operating manual, and ensure a clean and organized workspace to prevent accidents.

- How can I prevent tool-related injuries when operating a woodworking CNC engraving machine?

- Properly secure cutting tools, avoid wearing loose clothing or jewelry that could get caught in the machine, and never leave the machine unattended while it is running.

- Are there any specific safety certifications or training programs for woodworking CNC engraving machines?

- Some manufacturers offer safety certifications and training programs for their machines, and it is recommended to undergo these programs to enhance your knowledge and skills in safe machine operation.

- What should I do in case of an emergency or accident while using a woodworking CNC engraving machine?

- Familiarize yourself with the location of the emergency stop button on the machine, have a first aid kit readily available in your workshop, and know how to respond to different types of emergencies, such as tool malfunctions or material kickback.

- How often should woodworking CNC engraving machines be inspected for safety purposes?

- It is recommended to perform regular inspections of your CNC engraving machine, including checking for loose parts, worn-out tools, and any signs of damage that could compromise safety. Regular maintenance and upkeep are key to ensuring safe machine operation.

- What are some ergonomic considerations to keep in mind when setting up a woodworking CNC engraving machine?

- Ensure that your machine is positioned at a comfortable working height to prevent strain on your back and arms, use anti-fatigue mats to reduce stress on your feet, and maintain proper posture while operating the machine to prevent musculoskeletal injuries.

- How can I protect myself from dust and debris generated during CNC engraving operations?

- Use a dust collection system or wear a respirator to protect yourself from inhaling wood dust, regularly clean the machine and work area to remove debris, and consider installing barriers or enclosures to contain the dust within the workspace.

- Are there specific safety guidelines for handling different types of wood when using a CNC engraving machine?

- Different types of wood may present varying hazards, such as splintering or warping during cutting. It is important to understand the characteristics of the wood you are working with and adjust your cutting parameters accordingly to ensure safe and effective machining.

- What role does proper machine maintenance play in ensuring the safety of woodworking CNC engraving machines?

- Regular maintenance, including cleaning, lubricating, and calibrating the machine, is essential to prevent malfunctions and ensure safe operation. Follow the manufacturer’s maintenance schedule and guidelines to keep your machine in optimal condition.

- How can I stay up-to-date on the latest safety regulations and best practices for woodworking CNC engraving machines?

- Stay informed by attending workshops, seminars, and industry events focused on woodworking safety, subscribe to industry publications and newsletters, and follow reputable sources for safety information and updates in the woodworking community.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.