If you’re producing stone cabinetry or bathroom vanities — such as granite, marble, quartz, sintered stone, or engineered stone countertops with sink cutouts — you’ll need specialized CNC machines for stone processing. These are different from wood CNC routers and are built to handle high-density materials, water cooling, and precision cutting with diamond tools.

CNC Machine Cabinetry Bathroom Vanities

CNC machines are essential in bathroom product manufacturing, widely used for engraving, cutting, and drilling materials like artificial stone, quartz, and marble. They enable the precise shaping of countertops, washbasins, tea trays, and decorative edging, ensuring smooth finishes and intricate designs.

Unlike traditional methods, CNC machining allows for customized, complex shapes, which are crucial in modern bathroom design. Whether creating curved bathtub edges, seamless sink basins, or detailed surface textures, CNC technology enhances both production efficiency and design flexibility.

To meet these industry demands, we provide tailored CNC solutions that streamline processing techniques, optimize tool selection, and improve production accuracy. This enables manufacturers to reduce costs, enhance product durability, and achieve high-end craftsmanship in bathroom fixture production.

Most custom kitchen countertops and vanity countertops are made of marble, granite, quartz, rock slabs, and ceramic tiles because they are corrosion-resistant, pollution-resistant, high-temperature resistant, impact-resistant, waterproof, easy to clean, beautiful, and durable.

Decoration workers usually use portable masonry saws to cut personalized countertops. But the speed is slow with low precision, and the stone dust is easy to cause environmental pollution. Later, some stone workers chose CNC router machines to cut countertops. Although the precision was higher, the speed was too slow, even inferior to handheld masonry saws. In this case, a new type of smart automatic stone-cutting tool came into being. It is the CNC bridge saw, including 2 common types of 4-axis and 5-axis. The following is the 4-axis bridge saw with infrared positioning for automatic stone cutting.

Bridge saw stone cutting machine

5-axis bridge saw stone cutting machine integrates horizontal cutting, vertical cutting, 45-degree oblique cutting, round, oval, special-shaped layout, infrared positioning, CNC automation, and other functions. It is used to cut quartz, granite, marble, rock slabs, ceramic tile, slate, and other stone materials. It aims to solve the problem of time-consuming, labor-intensive, and high-cost high-end technology in the production process of stone countertops.

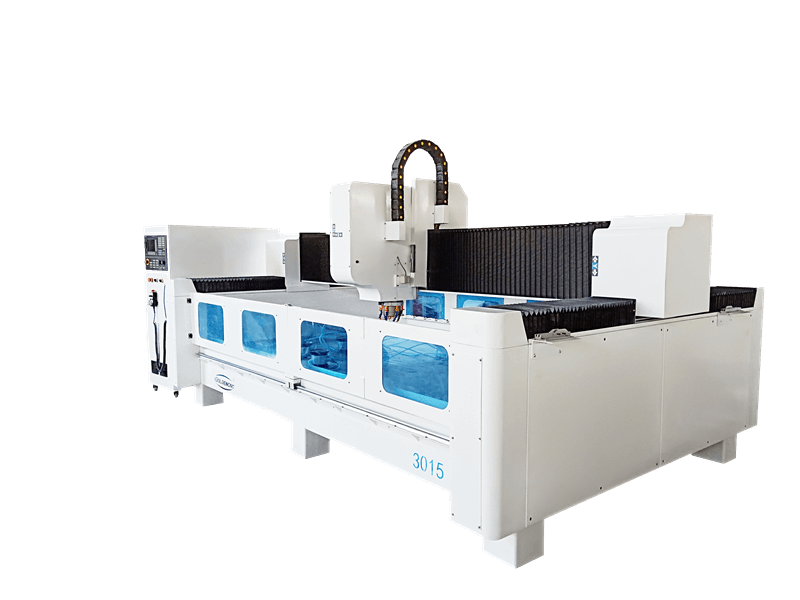

CNC stone cutting & polishing machine

CNC stone cutting & polishing machine is used for artificial stones, quartz stones, granites, marbles carving, cutting, polishing, drilling, engraving. Now the affordable automatic stone cutting & polishing machine for sale at cost price.

1. It is suitable for cabinets artificial stone, quartz stone countertops, granite, marble and sink.

2. European style edging, other heterosexual stone, ceramics, glass and ceramic stone drilling, sanding, edge down, carving, cutting, polishing, engraving.

Types of CNC Machines for Stone Work

There are various types of CNC machines available for stone work, each suited for different applications. Here are the most common types:

- CNC Bridge Saw: Ideal for cutting large stone slabs accurately and efficiently.

- CNC Router: Best for engraving and detailed designs on stone surfaces, perfect for intricate vanity designs.

- CNC Water Jet Cutter: Utilizes high-pressure water to cut stone, allowing for smooth edges and complex shapes without heat damage.

- CNC Machining Center: Combines multiple functions, including cutting, drilling, and polishing, into one machine for comprehensive stone processing.

Conclusion

CNC machines for stone cabinetry and bathroom vanities have revolutionized the stoneworking industry, providing unparalleled precision, efficiency, and customization options. Whether you are a professional contractor or a business owner in the stone industry, understanding the capabilities of these machines is crucial for elevating your craftsmanship and meeting client demands. Investing in the right CNC machine can significantly enhance your productivity and the quality of your stone products.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.