Introduction of Stone CNC Machining Centers & Stone CNC Routers

Stone CNC machining centers and Stone CNC routers, each exhibiting distinctive attributes suited for particular use cases.

Computer numerical controlled (CNC) machines play a vital role in the contemporary stone industry, facilitating efficient mass production and bespoke creations with equal panache.

Apprehending these disparities enables informed decisions regarding prospective acquisitions, aligning available resources with desired objectives.

Delve into our comprehensive comparison below to ascertain whether a stone CNC machining center or a stone CNC router best caters to your professional requirements.

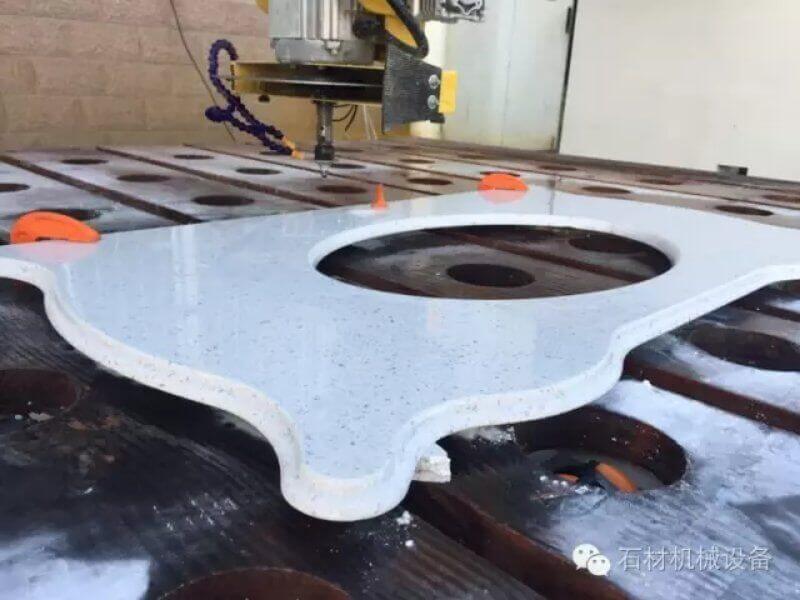

Stone CNC Machining Centers

CNC machining centers are more advanced and versatile than routers. They are designed for heavy-duty machining tasks and can work with a variety of materials, including stone, metal, and composites.

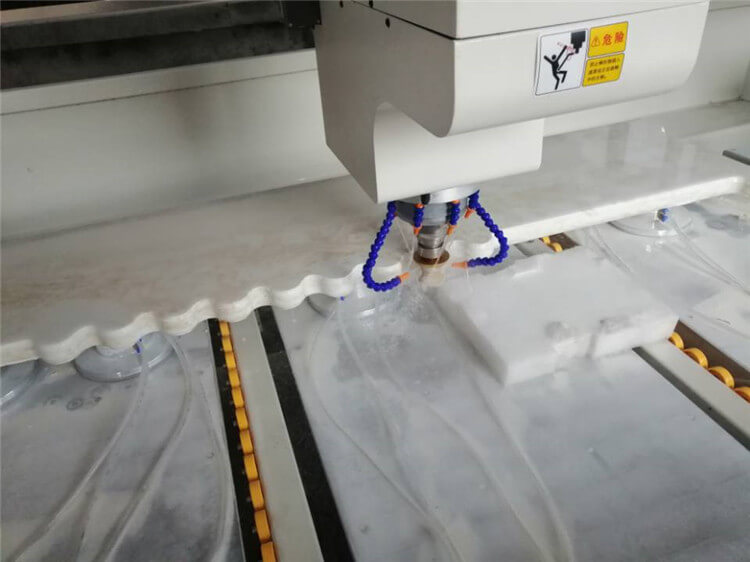

Stone CNC Routers

CNC routers are primarily used for cutting and shaping stone materials, such as granite, marble, and quartz. They are designed to perform various tasks, including engraving, carving, and creating intricate designs.

Definitions and Core Functionality

To initiate our exploration, familiarize yourself with foundational definitions and core functions inherent to both classifications:

Stone CNC Machining Center – Often synonymous with “multi-tool” or “gantry-style,” these units accommodate multiple tools concurrently, transitioning swiftly among them via automated procedures.

Common instruments incorporate specialized drill bits, profile cutters, and polishing attachments. Their purpose revolves around performing a multitude of tasks sequentially, expediting completion times and bolstering overall productivity.

Stone CNC Router – Recognizable by their stationary bed layouts and reciprocating spindle arrangements, routers specialize in removing excess material via routing, boring, or drilling operations.

Predominately leveraged for flattening, contouring, or pattern generation, these machines prioritize agility and precision over sheer force output.

Key Points of Differentiation

Having established essential descriptions, scrutinize salient distinctions separating stone CNC machining centers and routers:

Task Spectrum – Owing to their innate versatility, machining centers tackle broader scope assignments inclusive of finish honing, channel chamfering, hole drilling, and surface grinding.

Meanwhile, routers concentrate on dimensional reduction, achieving fine tolerances demanded by delicate trims, fillets, and intricate detailing.

Machine Architecture – Machining centers generally manifest larger footprints accompanied by considerable weight distributions, reflective of stout frames and reinforced supports needed for bearing cumbersome instrument arrays.

Conversely, routers tend toward compactness and portability, ideal for navigating cramped workshops or temporary job sites.

Workpiece Configuration – Machining centers traditionally impose size constraints commensurate with table dimensions, restricting input dimensions accordingly.

In contrast, routers employ vacuum pod suction systems compatible with oversized slabs, obviating limitations imposed by spatial confines.

Price Point – Inevitably influencing purchasing choices, price tags diverge substantively between machining centers and routers, mirroring respective technical capacities and utility ranges.

Prospective buyers must weigh expected return on investment against immediate expenditure budgets.

Conclusion

Choosing between a stone CNC router and a CNC machining center depends on your specific needs. If your focus is on artistic designs and versatility, a CNC router may be the best fit. However, if you require precision and the ability to handle complex machining tasks, a CNC machining center is the superior choice.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.