MDF cutting machine is a type of woodworking machine that is used quite extensively these days.

MDF cutting machines are also known as medium density fiberboard cutting machines. They are machines that help to cut the softwood or hardwood plates into perfect dimensional pieces which can then be a part of craft.

MDF cutting machines are also known for their enhanced dimensional stability which makes them perfect for a wide range of woodworking projects. The best reason for using the MDF cutting machines is that they offer the woodworking professionals the scope to create highly consistent and accurate products each and every time. Another excellent reason for using these woodworking machines is that they are extremely versatile when it comes to creating different types of products. This makes it possible for the woodworking experts to create different types of finished goods with little effort.

Some of the types of products that can be created with the help of these machines include furnitures, decorative items, storage boxes, architectural models, household items as well as various types of crafts. The best reason for using these machines is that they can be used for easily cutting to about 3 to 4 mm of depth. With a little bit of customization, these machines can be used for cutting even further than that.

The ease of use and flexibility offered by these machines makes them a staple in almost all woodworking factories.

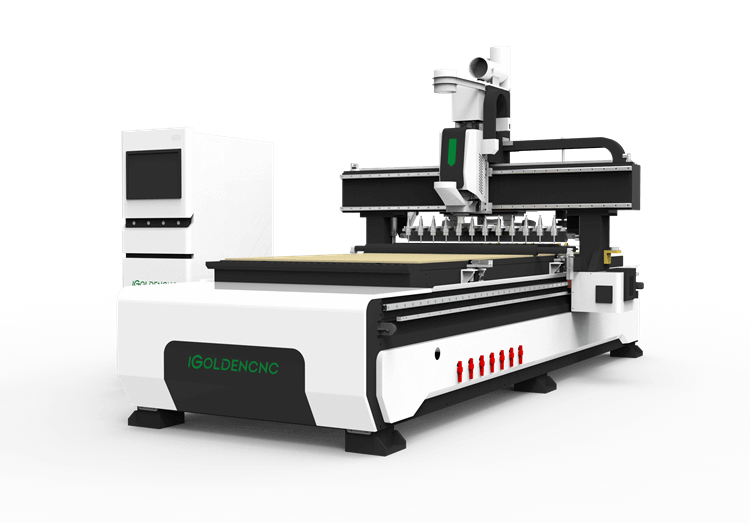

CNC MDF Cutting Machine

Therefore, it saves and ameliorates sheet utilization. Fortunately, the CNC nesting machine is commonly used in the furniture industry such as a cabinet, wardrobe, solid wood, paint-free, solid wood composite, and suite doors. Imagine what one CNC nesting machine has done for various homes, and office doors. If you want to bring panel furniture to life, the nesting CNC machine is your best buddy.

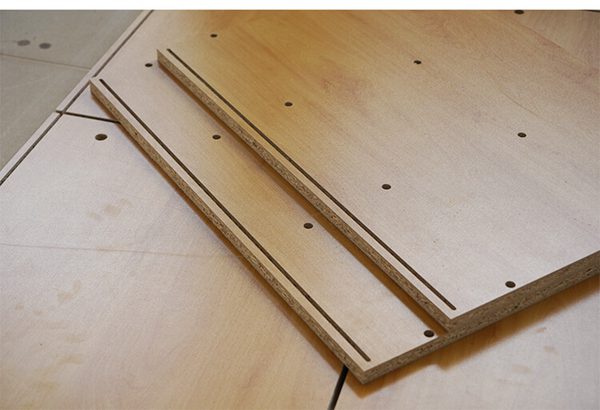

MDF boards have wide applications, so what’s the best way to cut MDF? The answer is CNC MDF cutting machine, which mainly includes MDF CNC router, CNC milling machine and MDF laser cutting machine. The MDF CNC machine has characteristics of high automation, high efficiency and high productivity. It is capable to cut MDF boards and engrave various CNC patterns of MDF surface according to your requirements as well.

Solid carbide double spiral flutes up-cut CNC router bits are good choice for cutting MDF. Two large grooves can easily remove chips and keep bits in balance during rotation. They are also high temperature resistant. Cutting MDF with CNC routers greatly improves the productivity while reduces the waste of raw material.

MDF in Furniture Production

In a nutshell, wood is crushed into chips, refined into fibre, mixed with glue and wax and compressed under a high temperature hot press. This in turn cures the glue which then binds the fibre together to become raw MDF.

Medium density fiberboard (MDF) is a high grade, composite material that performs better than solid wood in many areas. Made from recycled wood fibers and resin, MDF is machine dried and pressed to produce dense, stable sheets. (Note it’s built from recycled materials, thus qualifying it as “green”.)

MDF stands up better to changes in heat and humidity than solid wood. Solid wood boards typically expand and contract both horizontally and vertically when temperatures and humidity rise and fall. Because of this, cabinets, doors and paneling made from solid wood require care and maintenance.

MDF can be milled by CNC machines in one-piece frames with the center cut out for a panel. Because of its density, MDF does not move independently from the frame and the inserted panel does not need to float like the conventional five-piece solid wood door. Since the MDF panel doesn’t float within the frame, hairline cracks do not form along the edges of the panel or at the style and rail joinery.

MDF is readily available in panel sizes larger than those available for solid wood. These large sheets can be milled into bead board panels or wainscot paneling

Medium density fiberboard is the most appropriate material in producing high-end hotel furniture.

ADVANTAGES over solid wood

•Chemical substance could open ability to eliminate pests and wood worm.

•Humid condition causes less damages on MDF during long-term using.

•The fiberboard (MDF) brings about flexibility for designers due to its dimensional customization.

•MDF does not get cracks or splits under luxury hospitality furniture production.

•This material is reasonable choice for economic consideration.

laser cutting machine for MDF

Except for the foregoing MDF CNC router machine, we also have MDF laser cutting machine or MDF laser cutter. Laser cut MDF products are very commonly seen in our daily life, for example, laser cut MDF 3D letters, MDF photo frames, fixture and exhibition booth, children’s jigsaw puzzle etc.

The MDF laser cutting machine uses a high-power-density laser beam to irradiate the MDF without touch. So the machine will not scratch the board surface. The MDF laser cutter has the characteristics of high precision, fast cutting, smooth cut, and low processing cost.

- Hardwood: CO2 laser cutting has good adaptability to hardwood. Common types of hardwood such as oak, walnut, and cherry wood can be accurately cut by CO2 laser cutting machines. CO2 laser cutting can provide fine cuts and engravings on these hardwoods.

- Softwood: CO2 laser cutting is also suitable for softwood, such as pine, spruce, and cedar. Laser cutting can cut softwood quickly and can achieve detailed cuts.

- Plywood: CO2 laser cutting machines are efficient at cutting plywood, a material made from multiple layers of wood veneers glued together. Laser cutting can create complex designs and holes in plywood and is highly adaptable. Commonly used in furniture, construction, and craft manufacturing.

- MDF: CO2 laser cutters are ideal for processing MDF, a high-density board made of wood fiber and synthetic resin. Laser cutting enables smooth cut edges on MDF without the need for further processing.

Conclusion

Now that you have learned several good MDF CNC cutting designs and had a suitable MDF CNC machine to cut MDF board, it’s time for you to develop your own MDF business. The MDF CNC cutting projects can be very profitable due to the cost-effective feature of MDF. But be sure to pay attention to the concerns mentioned above when you cut MDF board. Besides, if you plan to produce MDF CNC cutting products but have issues with selection of a MDF CNC cutting machine, feel free to contact us.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.