CNC routers are invaluable across these industries, enhancing productivity, accuracy, and creativity. Whether for mass production or custom projects, their applications are vast and varied.

CNC routers are used in a wide range of industries, including making furniture, doors, cabinets, in woodworking, creating beautiful musical instruments, and much more.

What Industries Are CNC Routers Used In?

Furniture Industry

CNC routers are used heavily in the furniture industry to make bedroom sets, sectionals, table sets, office furniture, and more. Large wood, MDF, or other material sheets are common raw materials in the furniture industry, and CNC wood routers are perfect for processing them. CNC routers are also used to cut foam and plastics within the furniture industries.

CNC routers cut various furniture parts from the sheets, fillet the edges, engrave and cut patterns, and create holes, counterbores, and countersinks. This makes assembling CNC-cut furniture parts much easier.

Door Making

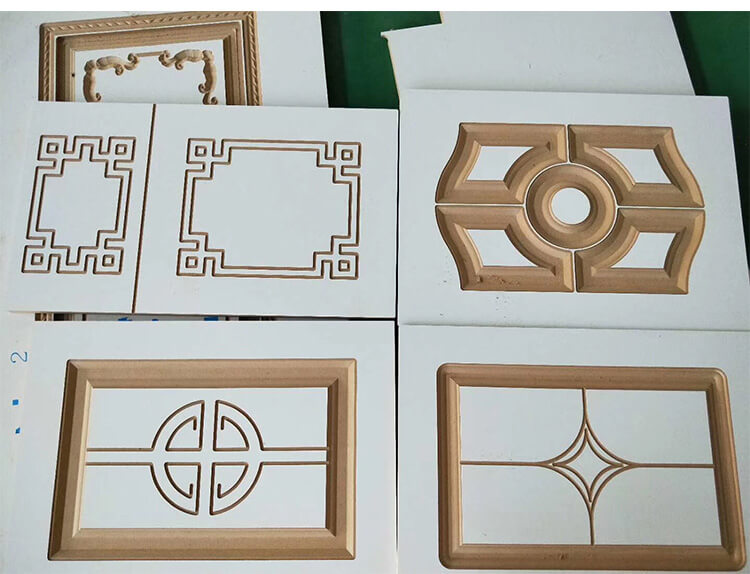

Another similar industry CNC routers are used in is door making, especially for doors with precise and intricate detailing.

CNC routers can cut wooden doors, and can also create door carvings on them. More advanced CNC routers can also cut placements for door handles, locks and door hinges, as well as drill holes for keyholes. They’ll also create holes and countersinks for the assembly of the handle and the hinges.

Some CNCs can even automatically feed themselves the raw materials and move the cut doors.

Cabinet Industry

Another industry that heavily relies on CNC routers is cabinet making. They’re used in a very similar way as the door making industry when cutting and machining cabinets.

CNC routers can cut all parts of the cabinet and create patterns, including creating custom panel designs and carving and engraving intricate patterns, and edge profiling and shaping.

More advanced machines can also bore the sides for cabinet joineries for doors and drawer fronts, shelf pin holes, and some CNC routers can even clean themselves from wooden debris automatically.

General Woodworking Industry Applications

We’ve already named some areas, such as furniture and cabinet making, but there are also other woodworking applications we’ll cover here separately.

CNC routers are excellent for making jewelry boxes, backgammon boards, chairs, shelves, dog houses, coffins, toolboxes, desks, and much more.

Custom woodworking items like customized chairs and desks may not see mass production, but they rely on CNC routers for producing lower numbers.

4-axis CNC routers can also make luxury 3D sculptures and chess pieces using rotary axes to cut curved surfaces, as well as rounded features on furniture. I have made chess pieces using the CNC head of my Snapmaker 2.0 before, using the rotary attachment.

Stone Industry

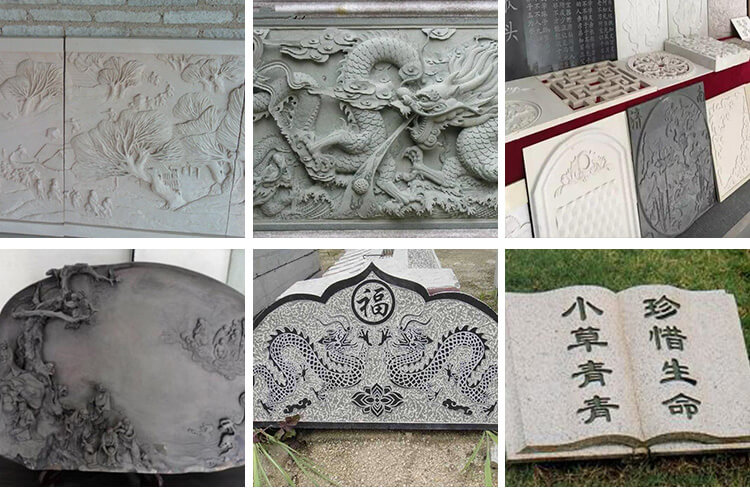

CNC routers have been widely adopted in the stone industry within the last decade to cut marble, granite, limestone, and other similar materials.

The stone industry uses large and powerful CNCs to cut stone, and create patterns on stone designs. CNCs are used to cut countertops for kitchens, create sink cavities, roofing, and cut various stones for buildings and constructions.

CNC routers can also engrave stones, and can be used to create gravestones, stone inlays for home decor, fireplaces, and other architectural projects.

While you won’t be able to cut stone with desktop CNC routers, there are specifically designed CNC routers for cutting stone – though they often cost tens of thousands to several hundred thousand dollars.

Mold Industry

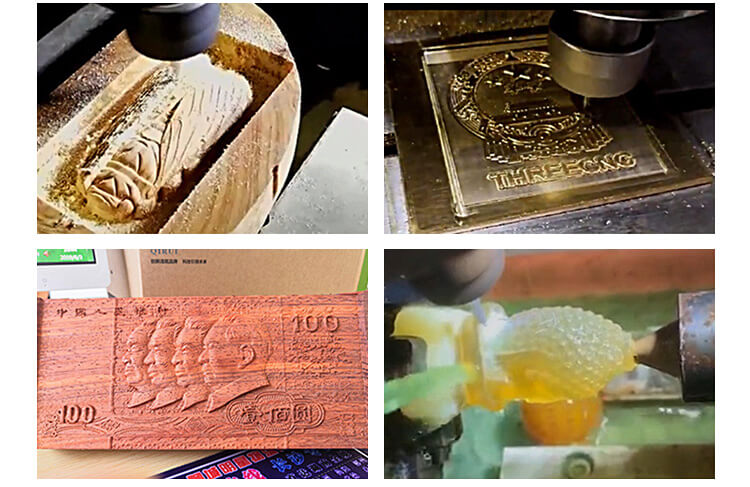

Injection molding is overall the best way to mass-produce most things. Rather than having to machine every piece, you can save money and scale production by CNC machining the mold, and then using these molds to make parts.

CNCs are used to create these molds, with CNC routers and mills used – your preferred option depending on the mold’s material, for example, mills are usually better for metals, whereas CNC routers are effective for plastics and foam, preferably if they have 4 or 5 axes.

CNCs are mostly used to mill mold cavities that are to be filled for injection molding, mold cores and inserts, finishing mold surfaces for accurate part production, and drilling holes into mold prototypes for things like injector pins, alignment pins, and cooling channels.

Musical Instruments

The vast majority of musical instruments are wooden and have some form of engraving. The size and shape of musical instruments are essential to their performance, so the precision and repeatability CNC routers offer makes them essential.

CNC routers are used to cut and shape guitar bodies and necks, violin features, and keyboard or piano keys.

CNC router machines can offer a precise, uniform finish that makes the ideal for the manufacturing process.

Advertising and Sign-Making

Advertising and sign-making often rely on permanent billboards or signage. CNC routers and lasers are excellent for these purposes. CNC routers can do a number of things for sign-making.

- CNC routers can cut ACM and anodized aluminum sheets and drill them for signs.

- CNC routers can cut wooden frames for signs.

- Routers can also engrave wooden signs.

- CNC routers are used in channel letter fabrication. They can cut the face and sides of letters out of aluminum and acrylic.

- CNCs can carve out precise letters out of wood and acrylic for hand lettering.

Jewelry Making

While CNC routers aren’t typically used for cutting gems themselves – with these lapidary tasks typically done by faceting machines instead using a grinding and polishing wheel – CNCs are sometimes used to create metal molds or settings for gemstone inlays.

CNC routers can cut some metals, and can create fairly accurate and intricate metal jewelry.

Plastic Industry

The use of CNC routers in the plastic industry is on the rise, and there are CNC routers specifically designed for cutting plastics, with CNC tools being designed that are optimized for plastic cutting.

Common plastics CNCs cut include acrylics, ABS, PVC, polycarbonate, polyethylene, and polypropylene.

These CNCs have air blast systems that direct compressed air onto the cutting area, preventing the plastic edges from burning as the CNC cuts the plastic.

CNC routers are used when making intricate or detailed designs with high precision. For example, some manufacturers use CNC routers to make underground spacers.

They’re also used to create:

- Plastic signage, and other displays and fixings for marketing

- Lighting fixtures

- Protective guards and enclosures

- Interior car parts (and some exterior body parts)

- Packaging

- Plastic prototypes

Conclusion:

The versatility and precision of CNC routers have undoubtedly transformed the manufacturing landscape across a diverse array of industries. By seamlessly integrating these advanced machines into their production processes, businesses have gained a competitive edge, unlocking new levels of efficiency, quality, and innovation. As technology continues to evolve, the impact of CNC routers is poised to expand even further, solidifying their position as essential tools for the modern manufacturing era.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.