In the dynamic world of advanced fabrication, the choice between 4-axis and 5-axis CNC routers can have a profound impact on the precision, flexibility, and efficiency of your operations. As technology continues to evolve, understanding the key differences between these two dimensional powerhouses is crucial for unlocking the full potential of your woodworking, metalworking, or custom manufacturing processes.

4 Axis vs 5 Axis CNC Router

4 Axis CNC Router

4-axis CNC router, with its ability to move along three linear axes (X, Y, Z) and one rotary axis, offers versatility in carving intricate designs, creating curved surfaces, and undertaking complex woodworking projects with precision and efficiency. This machine excels in tasks that require 3D machining and rotational cutting, making it a popular choice for industries such as furniture making, sign making, and prototyping.

Key Advantages of 4-Axis CNC Routers:

- Increased Dimensional Control: The addition of the fourth, rotational axis enables the machining of components with intricate geometric shapes and contoured surfaces.

- Enhanced Productivity: 4-axis CNC routers can automate multiple cutting and routing operations simultaneously, streamlining your fabrication workflows.

- Versatile Material Handling: These machines can accommodate a diverse range of material sizes, thicknesses, and compositions, making them a suitable choice for a variety of fabrication projects.

- Cost-Effectiveness: 4-axis CNC routers are generally more affordable than their 5-axis counterparts, making them an attractive option for businesses with tighter budgets.

5 Axis CNC Router

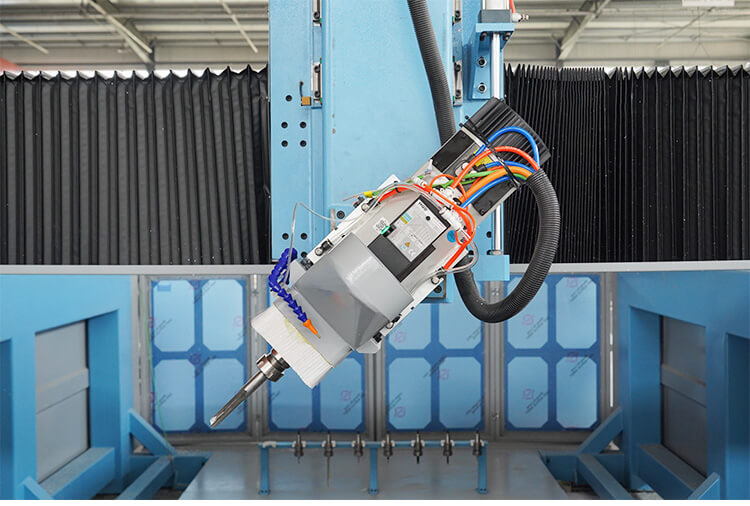

5-axis CNC router, with the added capability of a second rotary axis, provides even greater freedom and flexibility in machining operations. This machine allows for cutting from multiple angles and orientations, enabling the creation of more intricate and elaborate designs with minimal setups and increased efficiency. The 5-axis CNC router is ideal for sculptural work, aerospace components, mold making, and other applications that demand advanced machining capabilities.

Key Advantages of 5-Axis CNC Routers:

- Unprecedented Dimensional Control: The addition of a fifth axis provides unprecedented control over the positioning and orientation of the cutting tool, enabling the fabrication of intricate, multi-dimensional components.

- Enhanced Efficiency: 5-axis CNC routers can perform a wider range of cutting and machining operations in a single setup, reducing the need for manual intervention and streamlining your production workflows.

- Unparalleled Precision: The advanced control systems and programmability of 5-axis CNC routers deliver exceptional cutting and machining precision, ensuring the consistent quality of your finished products.

- Expanded Material Capabilities: These sophisticated machines can handle a wider range of material compositions, thicknesses, and geometries, broadening the scope of your fabrication capabilities.

v

v

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.