Looking for a versatile and powerful solution for 3D carving, cutting, and engraving across wood, foam, MDF, acrylic, and even light metals?

4-axis CNC wood router – a sophisticated tool that elevates woodworking to new heights of precision and complexity! This advanced machine offers a range of capabilities and possibilities for creating intricate designs, curved surfaces, and three-dimensional shapes with unparalleled accuracy and efficiency.

4 Axis CNC Wood Router with Swing Head

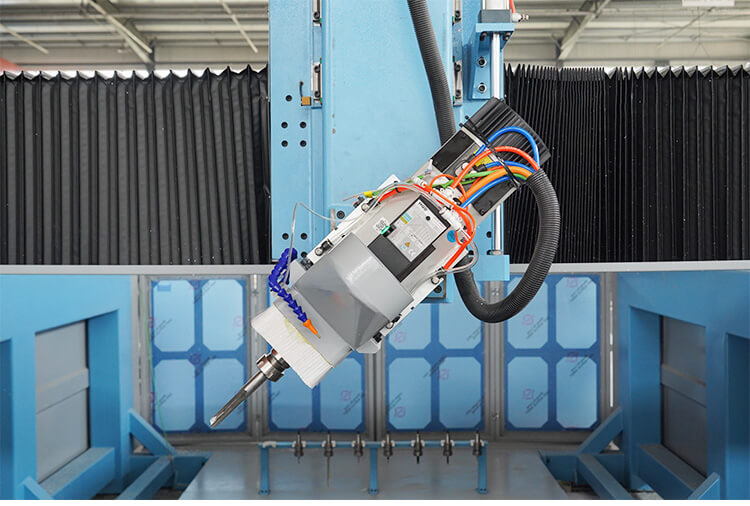

The 4 Axis CNC Wood Router with Swing Head is designed for advanced woodworking applications that require precise and flexible multi-angle machining. Unlike standard 3-axis machines, this model features a spindle that can tilt ±90°, enabling it to process intricate 3D shapes, curved surfaces, and undercuts with ease.

Whether you’re manufacturing high-end furniture, 3D wooden molds, musical instruments, or sculptural elements, this 4-axis router offers the versatility and power needed to meet your most demanding production needs.

Whether you’re working with wood, EPS foam, MDF, acrylic, or aluminum, this CNC router ensures smooth, accurate cuts. Available in sizes like 1325, 1530, 2030, and 2040, it’s widely used for making furniture, sculptures, advertising signage, and foam molds. Combined with a 9kW ATC spindle, heavy-duty frame, and precision servo motors, it’s the ideal solution for businesses that need fast, flexible, and accurate 3D machining.

Application of 4 Axis CNC Router Wood

- Furniture manufacturing – carving legs, doors, decorative panels

- Sculpture & model making – 3D statues, mold prototypes, columns

- Boat mold building – EPS foam pattern making with 5-axis extensions

- Artistic wood carving – statues, reliefs, frames, and large wood engravings

- Architectural decorations – cornices, capitals, and 3D details for interiors

- Foam packaging molds – EPS, EPE, and polyurethane material shaping

- Advertising and signage – 3D letters, logos, lightbox backgrounds

- Multi-surface part machining – perfect for custom 3D CNC jobs

FAQ of 4 Axis CNC Wood Router

What is the swing head in a 4 axis CNC router used for?

The swing head (A-axis) allows the spindle to tilt, enabling multi-angle cutting and engraving for 3D surfaces, curved edges, and undercut areas. What materials can I process with this machine? It’s perfect for wood, EPS foam, MDF, acrylic, plastic, resin, and light aluminum.

Can this machine do both flat and rotary wood cnc engraving?

Yes. With the optional rotary axis, you can engrave cylinders, sculptures, and round workpieces alongside standard flat panels.

How can I get a quote or customize my machine?

Simply contact us with your material type, working size, and application. We’ll provide a tailored quote and help you select the right model.

Can I carve human sculptures with this machine?

Yes, it’s ideal for 3D wood or foam carving, including human figures, statues, and large sculptures.

What is the difference between 3, 4, and 5 axis CNC routers?

A 3-axis machine moves on X, Y, Z; 4-axis adds a rotating spindle or rotary table; 5-axis includes simultaneous motion with A/C axes for full 3D control.

Conclusion:

4-axis CNC wood routers have emerged as a transformative force in the world of woodworking and fabrication, redefining the standards of precision, flexibility, and innovation. By understanding the remarkable capabilities of these cutting-edge solutions and leveraging their potential, manufacturers, woodworkers, and fabricators can unlock a new era of production excellence, solidifying their position as leaders in their respective industries. As the demand for advanced, versatile material processing equipment continues to grow, the strategic adoption of 4-axis CNC wood router technology will be a crucial step towards unlocking your organization’s full potential and thriving in the dynamic landscape of modern woodworking and fabrication.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.