CNC Drilling and Cutting Production Line for Wood Furniture Cabinet Door Design and Making

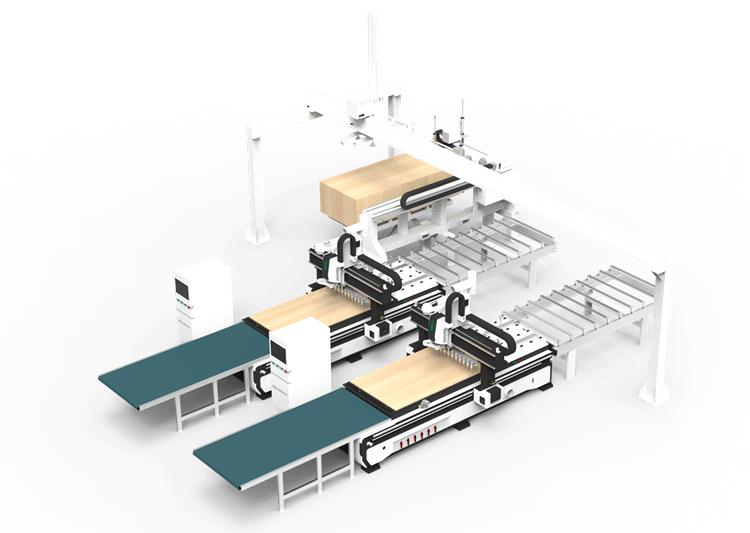

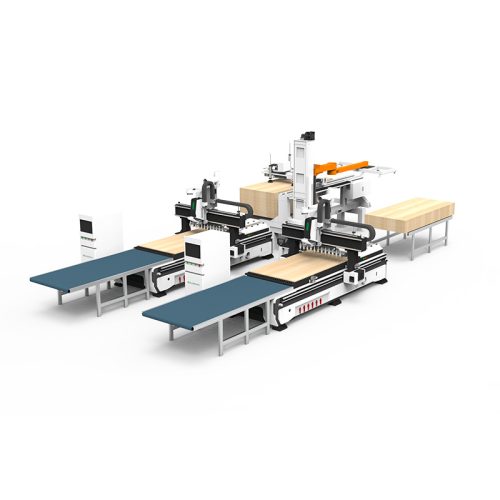

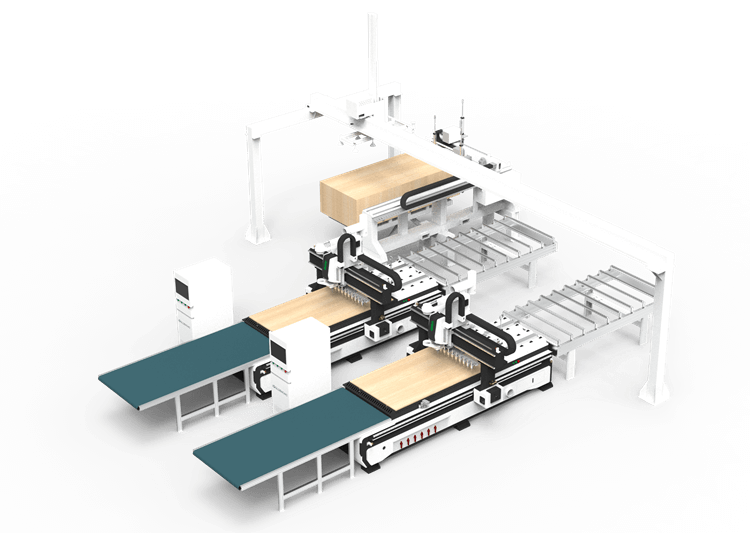

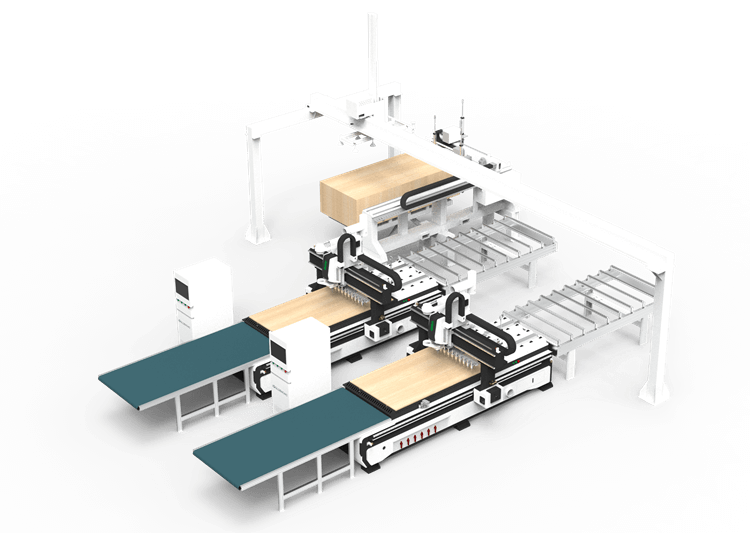

This production line adopts a highly efficient gantry robot combined with a modular design concept, innovatively realizing a “one-to-two” linkage production mode, and is designed to create intelligent and flexible production solutions for the woodworking industry.

Professional factory produce the woodworking Fully Automatic CNC furniture production line with drill cutting center cnc router machine / wood door machine production line. For this High-end woodworking cnc router center, Perfect Function, automatic feeding, playing a vertical hole. slotting, cutting, automatic feed in one step.

The gantry robot synchronously controls two cutting machines, significantly improving production efficiency and reducing manual intervention, meeting the needs of batch production and customization in the fields of furniture manufacturing, wooden crafts, and decorative materials.

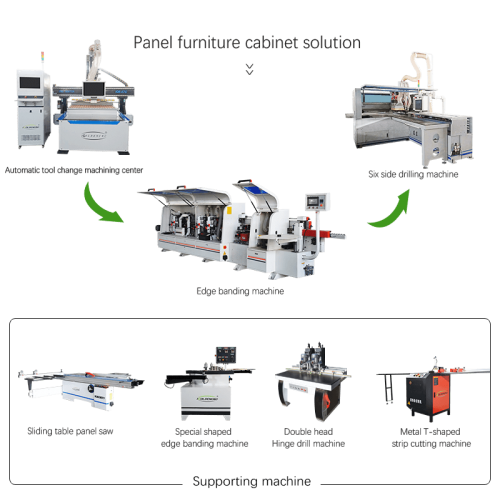

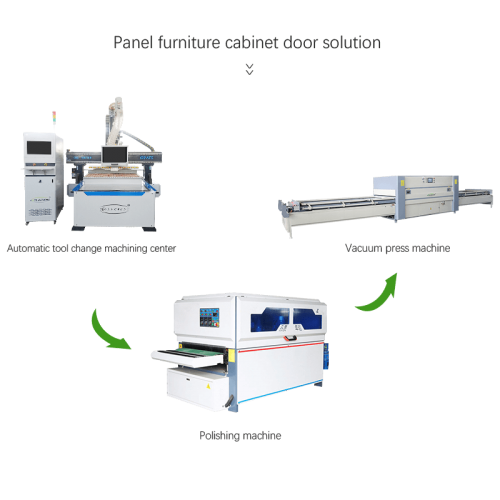

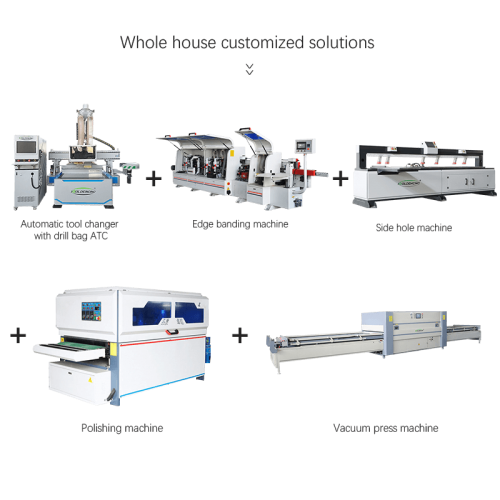

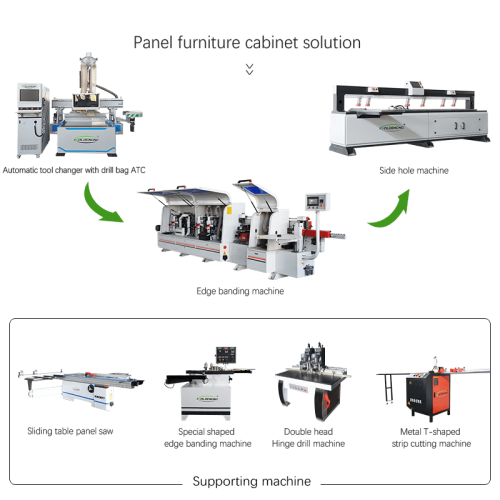

Whether you’re producing cabinets, wardrobes, or other types of panel furniture, our machinery integrates cutting, drilling, and edge banding for a seamless production workflow.

Custom Modern CNC Furniture Video

Processing process

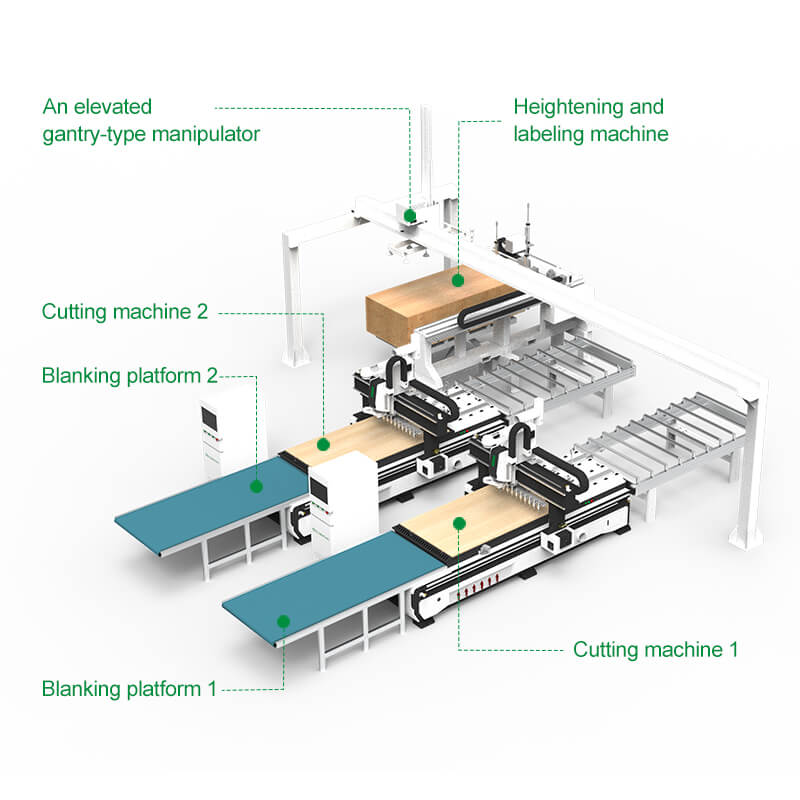

The lift below the elevated labeler can hold 60 sheets → The central control software sends the label information to the labeling machine →After the automatic labeling machine has finished labeling, the robot will distribute it to the No. 1 and No. 2 cutting machines. →The processing program is sent by the central control software to the corresponding cutting machine for cutting.→If the cutting machine has not completed its work, the robot will place the grabbed sheet in the labeling buffer area, and the labeling machine will continue labeling until all processed sheets are completed.

CNC Furniture Production Line Parameter

| Model | iGC-GL-1T2 |

| Robot | |

| Number of axes | 2-axis |

| Beam length | 10.2m |

| Number of suction cups | 8 |

| Suction cup load weight | Max. 100kg |

| CNC cutting machine | |

| Working area(X,Y,Z) | 1300*2500*250mm(Customizable) |

| Max. empty line speed | 60000mm/min |

| Max. operating speed | 30000mm/min |

| Spindle power | 9.0kw Air-cooled tool-changing spindle |

| Spindle speed | 24000rpm |

| Positioning accuracy | 0.03mm |

| X,Y axis transmission | Rack |

| Z-axis drive | Ball Screw |

| Repeat positioning accuracy | 0.02mm |

| Command language | G Code |

| Operating voltage | AC220V/380V, 50Hz |

CNC cutting machine + automatic unloading

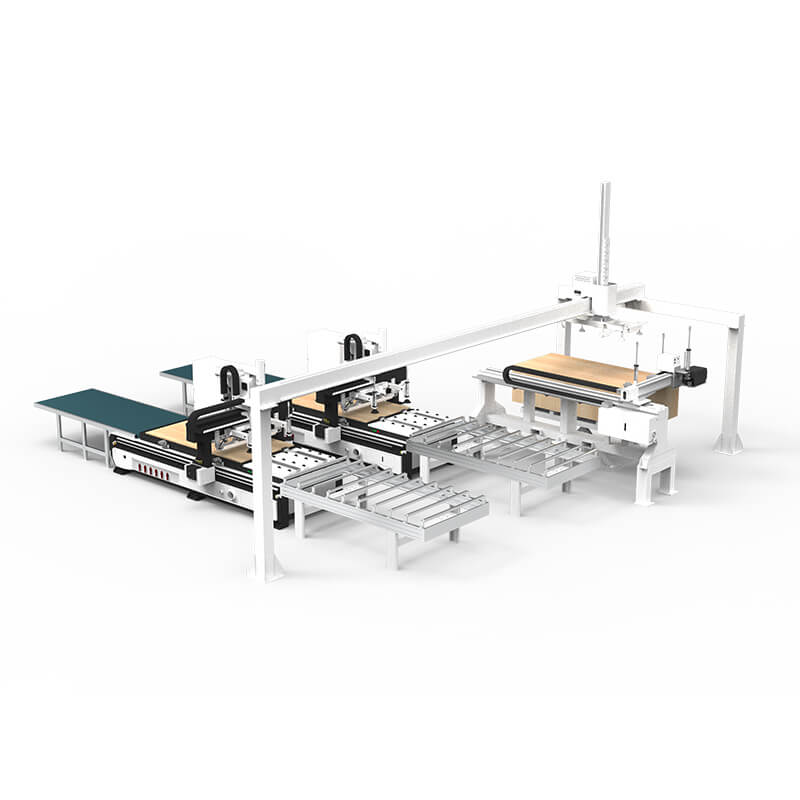

The two cutting machines work simultaneously, using professional cutting software, which can design and optimize the layout and positioning of the panels online, thus improving the utilization rate of the panels. Combined with the automatic unloading platform,the processing speed and efficiency are effectively improved.

Heightening labeling machine

The heightened labeling machine is equipped with an intelligent lifting storage platform, which supports the continuous buffer supply of 60 sheets of plate materials, breaking through the traditional single-time loading limitation.

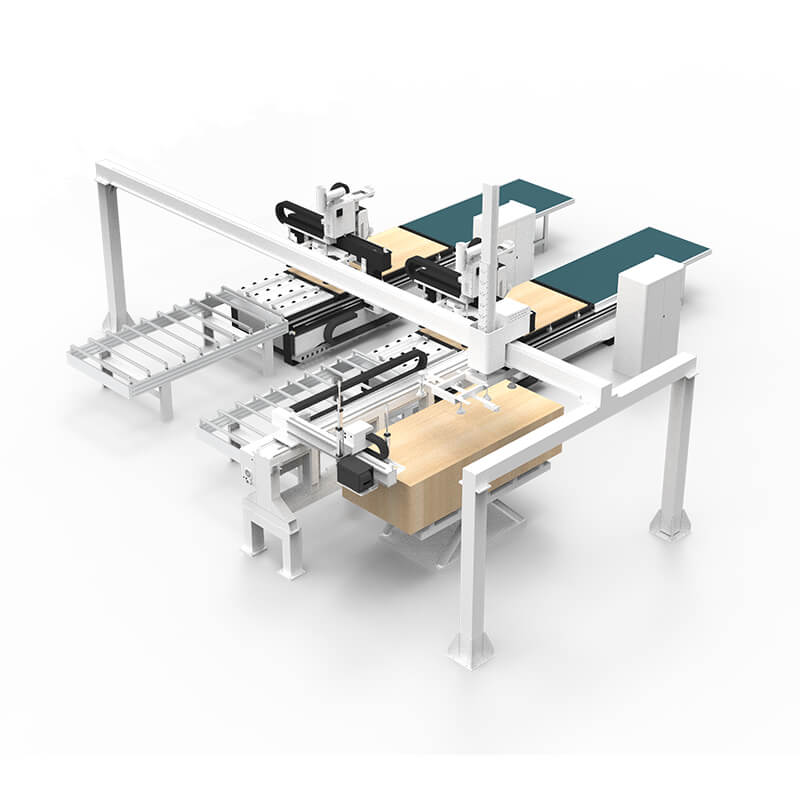

Heightened four-axis intelligent robot

The gantry robot is used to load materials and transport plates, and cooperates with two CNC cutting machines to grab, position and transport plates. It is flexible and efficient, and improves production efficiency.

Intelligent control system

The industrial-grade central control platform is used to realize the collaboration of three core functional modules: intelligent information distribution, unmanned labeling operation, and intelligent logistics scheduling. Through centralized control through the human-machine interface (HMI), manual intervention can be reduced by more than 75%, ensuring production stability and process consistency.

Key Features of Automatic Panel Furniture Production Line

Intelligent Scheduling:The central control system monitors the status of the cutting machine in real time, automatically and accurately distributes the labeling sheets to 1/2 devices, and the conveying positioning is ±0.2mm.

Zero-wait collaboration:Original dynamic caching algorithm: When the cutting machine is fully loaded, the robot automatically stores the boards to be processed into the unpowered drum, and the labeling machine continues to operate without interruption, shortening the overall cycle time by 22%.

Double production capacity release:One robot seamlessly connects to two cutting machines, feeding materials continuously 24 hours a day, reducing labor costs by 70%, and processing an average of more than 800 sheets per day.、

Error-free production:Laser navigation + vacuum suction cup dual error prevention avoids the risk of tilting/sliding during manual handling, and improves processing consistency to 99.9%.

Panel Furniture Production Line Application

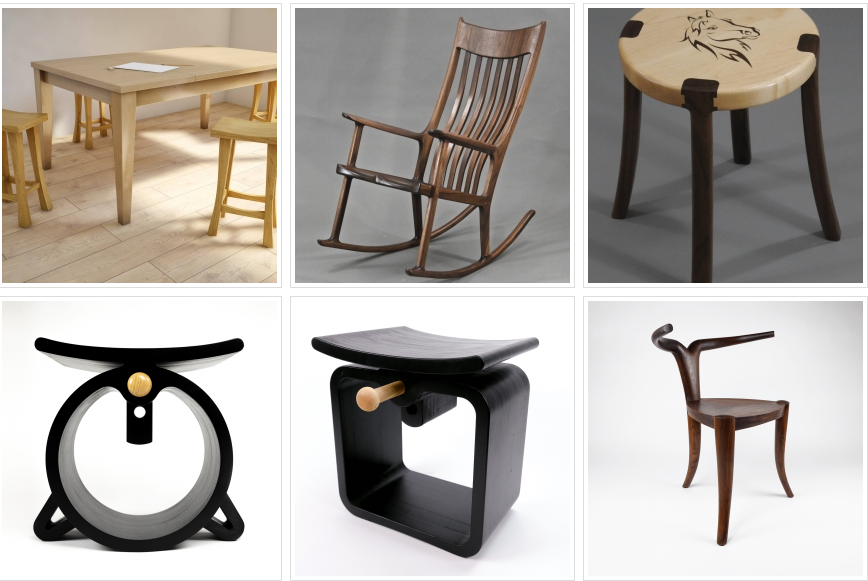

Smart furniture factory equipment production line is a mechanical equipment that integrates drilling and cutting functions. It is widely used in woodworking, wood furniture, hone cabinets, interior doors designs and manufacturing, building decoration and other industries. Its design structure enables two different processing tasks to be completed on one machine, improving production efficiency and work efficiency.

Contact Us Today to Get Price!

IGOLDENCNC wood furniture production line is an automated manufacturing system that can produce wooden products such as wooden furniture or cabinets more accurately and efficiently. The production line uses advanced CNC technology and integrates CNC machines at each processing stage to ensure high precision, high productivity and high compatibility. Whether it is furniture products such as cabinets, tables, chairs or wardrobes, they can all be mass-produced and standardized using this production line to meet the diverse needs of the market.

1. Control System: The integrated CNC control system and user interface are the heart of the entire production line. With a straightforward style, the operator can conveniently enter processing criteria and keep an eye on the production process to ensure accurate control at every stage.

2. Automatic Loading Platform: The automatic loading can automatically grab wooden boards with a mechanical arm or gantry type vacuum suction cup and place them in an orderly manner on the conveyor belt.

3. Feeding Conveyor: As the starting point of the CNC wood furniture production line, the feeding conveyor is responsible for stably and accurately feeding raw materials (such as wooden boards) into the processing system, ensuring the subsequent processes.

4. Automatic Labeling System: This system labels each finished board to ensure product traceability throughout the production process, as well as facilitating subsequent assembly and sorting.

5. Two-Side Drilling Machine: The drilling machine accurately drills holes and grooving on the front and back surface of the wooden board according to the design requirements, ensuring that the furniture parts will perfectly connect when assembled, and also meeting the needs of the next step of processing.

6. CNC Nesting Machine: This CNC wood furniture production line is equipped with an advanced CNC nesting machine. The cnc router machine can precisely cut the wood panels into the required shapes and sizes according to a predetermined program. Both straight line cutting and complex curve cutting can be completed quickly.

7. Edge banding machine (optional): The edge banding machine can apply a protective and decorative finish to the edges of the boards, which not only improves the durability and appearance of the product, but also meets the processing needs of high-end furniture.

As a furniture production line supplier, we are aware of the role and effect of CNC wood furniture production line in the field of furniture manufacturing. The production line has revolutionized the furniture manufacturing process with the combination of automated systems and high-precision CNC machines, and can meet the diverse production requirements of both industrial and real estate furniture. The following are the core application areas of the production line:

Modular furniture manufacturing: The CNC wood furniture production line is an ideal system for producing modular furniture systems, including kitchen cabinets, bathroom cabinets, modular wardrobes and storage cabinets. The CNC router and CNC drilling machines ensure the accuracy of dimensions and hole positions, making the assembly process of modular components smoother, improving overall production efficiency and product quality.

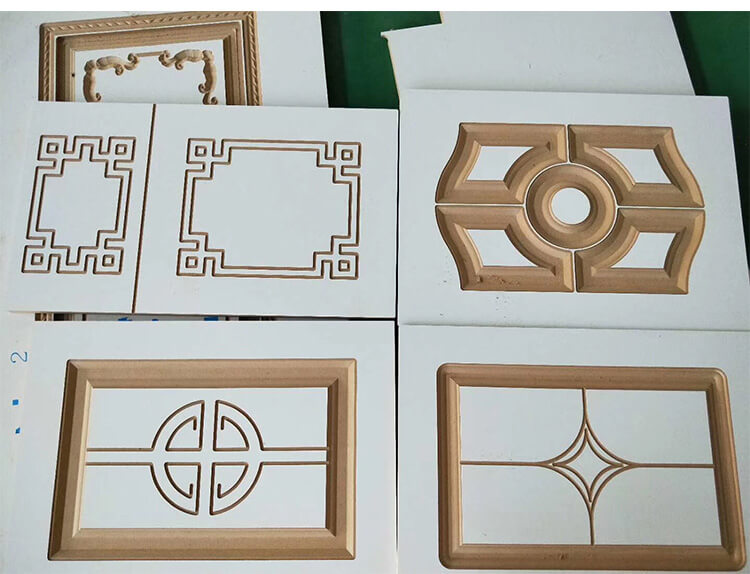

Custom furniture production: With the increasing demand for high-end furniture and personalized customization, CNC systems excel in custom furniture production. It supports custom shapes, sizes and designs, can engrave complex patterns and decorative details, and quickly adjust production specifications according to customer needs to meet the market’s individual needs.

Office furniture manufacturing: In the office furniture sector, the CNC wood furniture production line is capable of mass-producing desks, chairs, partitions and more, ensuring consistent product quality. With precise ergonomic design, high-durability edge banding and precise assembly, the line provides a high-volume, low-cost production solution for corporate projects.

Home furniture production: CNC wood furniture production lines are extensively used in the production of home furniture such as dining tables and chairs, coffee tables, beds and headboards, TV cabinets and entertainment equipment. The system strikes a balance between appearance and performance, allowing suppliers to produce furniture products that are both elegant and sturdy.

Production of cabinets and shelves: This CNC wood furniture production lines can produce a wide range of cabinets and shelves, including integrated or freestanding shelves, cabinet systems, display cabinets and bookcases. An automatic labeling and cutting system ensures that each product fits perfectly with the layout, thereby improving the overall quality and uniformity of the product.

High-end and luxury furniture manufacturing: For high-end furniture manufacturers, the CNC system can precisely machine complex styles and contours, use high-quality products to reduce waste, and enhance the premium look with edging and labeling to meet the needs of the high-end market.

CNC solid wood furniture production lines have not only changed the production model of the woodworking and furniture manufacturing industry, but also helped manufacturers meet diverse market demands while remaining cost-effective and environmentally sustainable by improving precision, efficiency and design flexibility. As a supplier, we are committed to providing customers with efficient and reliable CNC solid wood furniture production lines that help them stand out in the fierce market competition.

- Increased Efficiency: By automating key processes, manufacturers can significantly reduce production times while maintaining high-quality standards.

- Consistency: Automation enables manufacturers to produce furniture with consistent precision, minimizing the likelihood of errors.

- Cost Savings: By minimizing manual labor and material waste, manufacturers can lower their production costs while improving overall output.

- Customization: Our machines’ adjustable settings provide flexibility, enabling manufacturers to fulfill a variety of custom orders.