CNC Stone Countertop Cutting Machine

Stone processing center is a CNC automatic engraving high-tech equipment, mainly used for the processing of stone countertop, can achieve a feeding to complete all the processes of countertop processing. Stone countertop copying, special-shaped processing, grinding Roman edge, treatment of circular arc after retaining water, cutting basin holes, grinding basin along, polishing and other processes can also do stone relief carving.

Widely used in kitchen countertops, bathroom countertops, stone tabletop, coffee table countertop, TV counter surface processing, can also be used in billiard table, welcome table countertop, ordering table and other stone countertops.

CNC Stone Fabrication Machining Center Video

Stone CNC Machinery Parameter

| Technical indicators | parameter |

| Model | iGS-ATC-3015 |

| Working area | 1500*3000*500mm |

| Max. Running Speed | 20000mm/min |

| Max. Working Speed | 10000mm/min |

| Spindle power | 7.5kw Water cooled tool change spindle |

| Spindle speed | 8000rmp |

| Positional accuracy | 0.05mm |

| Repositioning Accuracy | 0.02mm |

| Command Language | G code |

| Working Voltage | 380v/50Hz |

If you need more detailed information, please inform us as soon as possible.

Main Configuration

| Name | Manufacturer/Brand |

| Machine Body | Square Tube Welding Structure |

| Gantry | Steel Structure |

| Spindle | Mechanical spindle |

| Spindle drive motor | Alpha |

| Worktable | Profile Clamping Table |

| Guide Rails | Taiwan HIWIN |

| Rack | Taiwan YYC |

| Ball Screw | Taiwan TBI |

| Driver | Weihong |

| Reducer | Japan SHIMPO |

| Electrical Components | SCHNEIDER / CHNT |

| Lubrication System | Electric oiling |

| Control System | NCSTUDIO |

CNC Stone Machining Center Description

CNC stone machining center is a stone fabrication machine for the making of stone kitchen sinks, stone countertops, basins, etc. It integrates edging, polishing, drilling, milling, and special-shaped cutting.

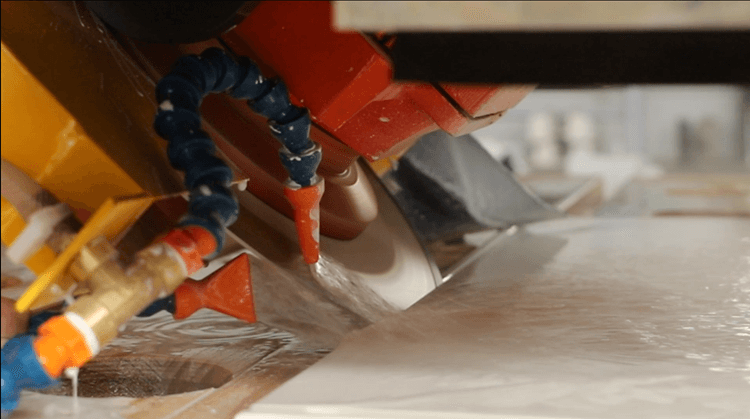

Water cooled automatic tool change spindle

5.5KW/7.5KW water-cooled tool change spindle, high rotation accuracy, small vibration, low noise, good heat dissipation, grease lubrication high temperature resistance, durable, long life.

12 Linear Tools Magazine

CNC Stone Machining Center With Linear ATC Positions for stone cutting, profiling, Edging, milling,

Upgraded Intelligent Control System

NC65 Series Controller Faster Responsible & Strong Function Inset CAM/CAD design software

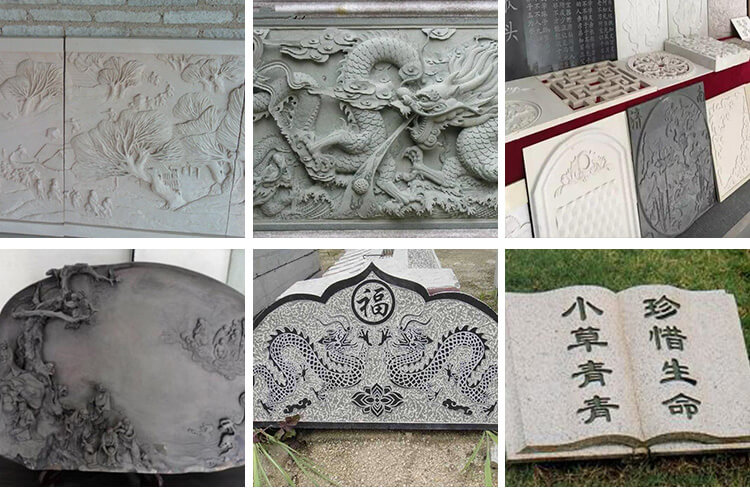

Applications of CNC Machining Center for Stone Cutting and Polishing:

1. Suitable for Natural marble, granite, quartz, bluestone, sandstone, artificial stone, tombstone, milestone, ceramic tile, jade, crystal, ceramics, glass, plastic, wood, bamboo, cambered surface, sphere, stainless steel, iron, copper, aluminum, titanium alloy, can doing 3D embossment, and line engraving, bevelling, drilling 2D engraving.

2. Suitable for European style edging, heterosexual stone, ceramics and glass drilling, sanding, edge down, carving, cutting, polishing, engraving.

Samples of CNC Machining Center for Stone Cutting and Polishing:

1. It’s high efficiency and low cost. For example, it just takes 30 minutes to auto-processing 2.44*0.75m quartz stone board.

2. CNC stone machining center can do many process such as polishing for back splash ,former anomalous edge, cutting and polishing water tap hole through the automatic tools changing.

3. High-precision screw and guide: the use of screw, guide renowned German manufacturer has provided.

4. CNC machining center for stone is researched and developed by our company independently.

5. X, Y axis using the original oil-immersed lubrication. Coupled with effective waterproof, dustproof structure to ensure high precision machining and screw maximize service life of the rail.

6. CNC software: for UncGraphics. NX3.0, Mastercam9.0 other software, set the CAD / CAM as a whole, through digital analysis, design, the product was processed to support procedural pre / igs / scep / dxf / dwp and other documents.

7. Automatic tool changer system: vertical-type ATC system makes the whole process from the hole, cutting, shaping and polishing to a variety of milling processes go, the full realization of a high degree of automation.

8. Tool and abrasive: with a large number of imported and domestic variety of tool and abrasive and shapes, and a variety of processing requirements.

9. CNC stone machining center can also be used for processing washing pool and European background wall. To process high-quality products,this model is a necessary equipment for the well-known brand who process counter-top.

- Enquiry. Feel free to tell us what material you want, what is your max working size, and what product you want to do. The budget is also welcome.

- Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos, and prices to you according to your request.

- Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture, and inspection.

- Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you. After the confirmation, the stone cnc router equipment will be shipped by sea through my or your agent.

- After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.

- Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.

his kind of stone countertop CNC machining center adopts an automatic tool change system (ATC processing system) and an automatic water circulating system. So that it can achieve a great processing effect without manual participation in the processing. Therefore, the ATC stone machining center has more outstanding automation. And the entire stone processing is completely conducted by the preset instructions for grinding, polishing, drilling, milling, and other actions. Then the seamless intelligent processing can be realized and the labor is better liberated. This kind of CNC quartz stone machining center is designed to solve the problems, such as time-consuming, labor-intensive, and high-cost in the production of stone countertops. At present, such kind of CNC stone center has a wide application in the processing of various stone countertops such as kitchen countertops, bathroom countertops, bar counter, coffee tabletops, stone tabletops, TV countertops, etc.

1.Wide Application

It can realize the functions of roman edge, rear-arc water retaining, upper middle and lower basin, special-shaped cutting, and grinding.

2.Environmental Protection

The whole process is automatic and environmentally friendly. And this kind of stone CNC grinding center for sale also builds a dust-free workshop that rejects pneumoconiosis.

3.Simple Operation

It’s easy to learn that even ordinary workers can get started in only one working day. It means that you will be more worry-free if using this kind of stone CNC machining center.

4.High Automation

This kind of ATC stone CNC machining center adopts an automatic tool change system and an automatic water-circulating system. It will be easy to achieve a great processing effect without manual participation in the processing.