CNC Bridge Saw

CNC (Computer Numerical Control) bridge saws are specifically designed to handle the unique requirements of processing a wide range of natural and engineered stone materials, including granite, marble, quartz, and more. These advanced systems utilize computer-controlled cutting blades to perform intricate cutting, shaping, and profiling tasks with exceptional precision and automation.

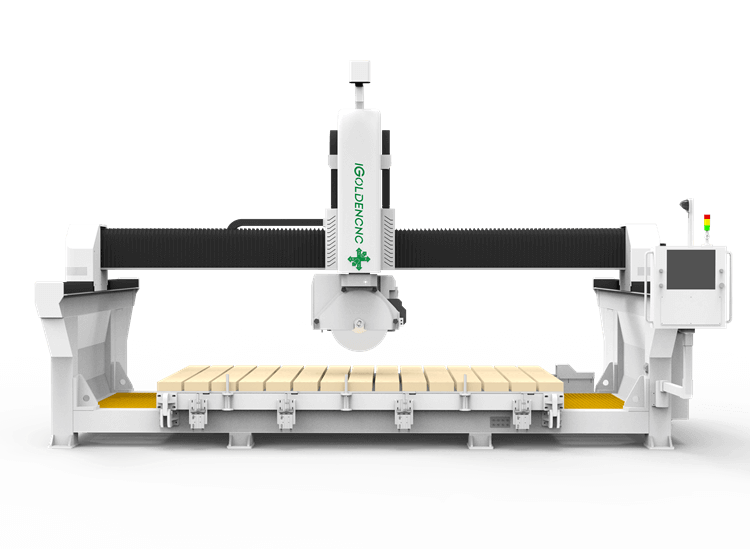

5-Axis Bridge Saw

IGS-B (Pro) 5+1 Axis Stone Bridge Saw is a high-end intelligent processing equipment deeply customized for the stone industry. Featuring an innovative 5+1 axis linkage structure, heavy-duty steel frame, and military-grade precision transmission components, it efficiently processes various hard materials including quartz, sintered stone, granite, and marble. Designed with multifunctional integration and intelligent operation at its core, this machine enables end-to-end processing—from basic cutting to complex 3D contouring—through a unified CNC system. Significantly reducing manual dependency, it delivers a material-saving, time-efficient, and labor-saving all-in-one solution for applications ranging from small stone workshops to large-scale architectural projects.

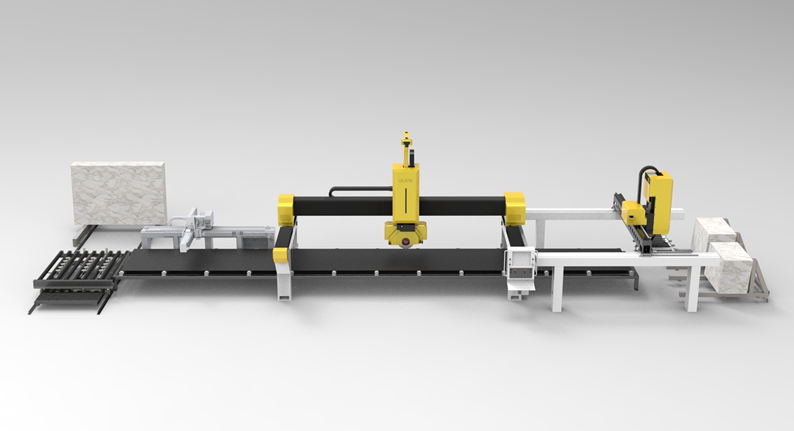

Online production solution

It can be connected to the automated assembly line to realize unmanned operation of the entire process of loading → positioning → processing → sorting, meeting the needs of 24-hour continuous production.

CNC Bridge Saw Video

Bridge Saw Parameter

| Technical indicators | parameter |

| Model | iGS-B3620(Pro) |

| Stroke of X axis | 3600mm |

| Stroke of Y axis | 2000mm |

| Z-axis stroke 1 | 255mm(Blade Diameter 400mm) |

| A axis | 0-90° |

| C axis | 360° |

| Saw blade motor power | 15kw/18.5kw/22kw |

| Spindle | HQD 6KW air-cooled spindle |

| Blade Diameter | 350-500mm |

| Input power | 3-phase AC 380V/220V 50-60Hz 10A |

| Body | Heavy duty bed |

| Gantry | Steel structure |

| Table | Automatic copy flip feeding |

| Guide rail | Taiwan HIWIN |

| Rack | Taiwan YYC |

| Screw | Taiwan TBI screw 5010 |

| Motor | IGOLDENCNC |

| System | IGOLDENCNC |

| Water pump | Standard |

| Standard configuration function | Table flip, cross red light positioning, tool setting instrument, dial indicator, tool hanging, table cleaning, working camera、Pressing |

| Optional Functions | Pressing, suction cup displacement, photo layout, probe, dust-free installation measurement software |

6KW air-cooled spindle

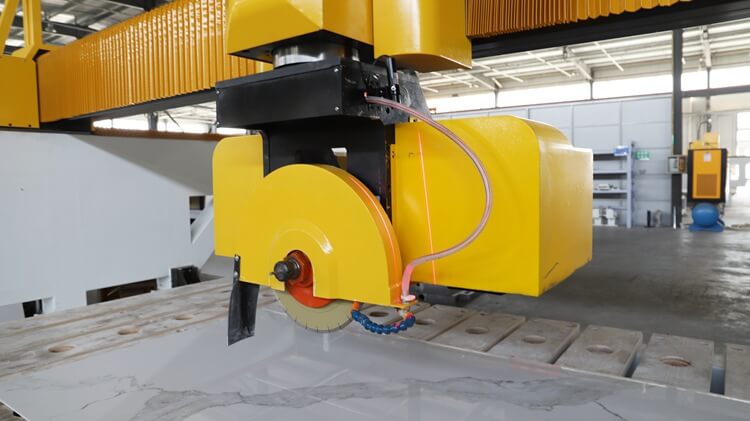

The machine head supports 360° free rotation and 90° multi-angle tilt, breaking through the limitations of traditional cutting. It can accurately complete complex processes such as straight line cutting in any direction, arc/circular contour processing, 45° bevel joints, and special-shaped internal corner carving. It is particularly good at fine operations such as cabinet countertop openings (basin holes/stove holes) and horse belly edge shaping.

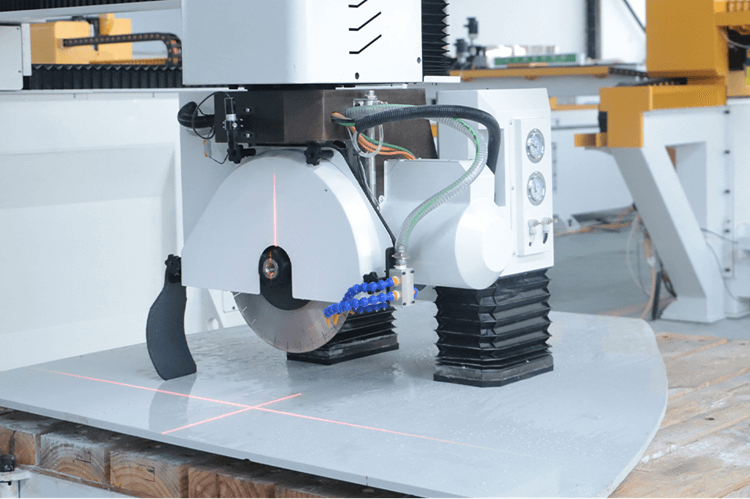

Laser positioning

The cross red light projects the cutting line to intuitively display the processing trajectory. Combined with the automatic tool setting instrument and probe (optional), it can compensate for tool wear and plate thickness differences in real time to ensure processing consistency.

Copy feeding system

The standard 86° automatic flip table supports fast loading and unloading of single 800kg heavy panels, reducing the intensity of manual handling.

Human-machine collaborative control

Equipped with IGOLDENCNC professional system and 10-inch industrial touch screen.

① One-click import of CAD design drawings in the graphical interface to automatically generate processing codes;

② Real-time monitoring of equipment operation status, automatic alarm for abnormalities;

③ Support for offline programming and cloud storage of processing data, greatly reducing the operating threshold, and new employees can start work after one day of training.

Vacuum suction cup displacement (optional)

A single adsorption area can adsorb a maximum of 200kg of plate, replacing the manual adjustment of the plate position and avoiding overcutting accidents caused by processing misalignment. It is especially suitable for continuous processing of large plates.

Photo layout (optional)

By using high-precision industrial cameras to scan the texture and defects of the plate, taking photos automatically, and combining with the optimal cutting path, the plate utilization rate can be increased by 15%-20% and manual typesetting errors can be eliminated.

The camera cover is designed to open and close automatically to prevent dust and maintain hygiene.

Application

This 5+1 bridge saw machine can complete the cutting, chamfering, trimming, etc. of various stones, and can realize countertop cutting, Roman column cutting, arc cutting, etc. It can be used in sanitary ware, stone furniture, interior decoration and other industries. It is used to make washbasins, bathroom countertops, kitchen countertops, etc.

5 axis CNC bridge saw adopts a PC-based five-axis linkage numerical control system for stone machining. The tool is controlled by three linear axes and two rotary axes, and the two rotary axes rotate around the X axis and the Z axis respectively. The automatic function of cutting, engraving and milling with complex pentahedral features is mainly used for the processing of high-quality stone decoration with complex surfaces in multi-dimensional space. The stone industry has undergone many product technological changes. The technical characteristics and advantages of the processing equipment whose tool motion trajectory is controlled by 5-axis and 6-axis linkages are becoming more and more obvious. The CNC five-axis bridge stone cutting machine is a professional stone machining equipment with outstanding flexible manufacturing ability and high automation, which uses a diamond disc saw blade as the main cutting tool.

The 5 axis CNC bridge saw can cut any shape of stone lines, arc edges, duckbill edges, straight edges, beveled edges, non-slip grooves, dry hanging grooves, sink processing, and special-shaped edge forming.

1. Countertop cut: blank slab cutting, rear gear cutting, reverse buckle cutting, hanging material, L-shaped table to length, corner cutting reserved, 45-degree chamfered front mouth, pot hole, stove hole, Diagonal line cutting, cutting at any angle of the wall crenel.

2. Automatic cut: Realize the import of CAD drawings, cutting completely according to the drawing style, no need to enter complex data.

3. Bridge cut: It has all the functions of bridge cutting equipment on the market.

4. Roman column cut: Cut the square Roman column main board and both sides at one time, and simultaneously chamfer 45 degrees on both sides to complete the Roman column hole cutting.

5. Arc-shaped line cut: Install the line grinding head to complete the arc-shaped line shape, and cut into a rough arc-shaped line as a whole, which requires manual polishing.

6. Concave-convex cut: According to the arc, grind out the desired convex or concave plate. It is mainly used for grinding and making curved plates of special-shaped background walls or special-shaped decorative panels. 7. Abnormity cut: To solve the problem of uneven walls, cut out asymmetric quadrilaterals or isosceles trapezoids.

Through the optimization of the process parameters by the numerical control system, the product data files can be stored in modules and called manually. The ideal effect of extremely coordinated movement of each precision component is realized. The process of machine cutting stone slabs can realize automatic and intelligent cutting of stone materials through the pre-setting of the cutting coding program and the automatic operation of the cutting process, so as to achieve the mass production of stone slabs.

1. The integrated design gives the machine more advantages, such as occupying small space, easy installation and debugging, high precision, stable performance, easy operation and so on.

2. Bridge, sliding rails and blade holder are built in strong and stiff cast iron for stability, durability and low resonance.

3. Cutting head rotate 90°, tilting 45° suitable for chamfering cutting.

4. 0° to 360° cutting head rotation and 0° to 90° cutting head tilting.

5. The worktable installs independently, the hydraulic console panel level 0, 45°, 90° turns. Worktable tilting vertical turn 85°, easier and safe loading raw materials.

6. The CNC bridge saw is made up of main motor, longitudinal slicing part, worktable assembly, electric control system, hydraulic system and so on.

7. The CNC bridge saw is equipped with infrared tool setting gauge, to accurately adjust the cutting size.

8. Once all the parameters are well setting, it is not necessary to have workers watching on machine. It will automatically stop once it finishes the cutting. It is an ideal automation equipment of stone slab cutting machine.

5 axis CNC stone bridge saw has the automatic cutting, milling, engraving and drilling processing of products with complex pentahedral features, and can process products with arbitrary curved surfaces and shapes, with fast processing speed, high running accuracy, and easy and convenient operation. We can provide remote control, remote programming (according to customer needs, the processing of complex shapes can provide remote programming services), processing files, remote fault diagnosis and other services. The system software can provide a variety of product processing modules with different rules, and directly select simplified programming according to processing needs (complex programming by professionals is not required). It can simulate the machining running track.

Durable

Good quality steel is used as the mechanical parts and reliable electric parts are used to guarantee high reliability & durability.

Precise

1. Crossbeam movement (Y-axis) along linear guide way with high precision.

2. Z-axis movement by lead screw.

3. Magnetic ruler is adopted for slicing measure.

4. Laser device for accurate alignment.

User-Friendly

1. Touch screen contral panel and all 3D movement is controlled by micro computer to realize automatic operation available.

2. Both manual and automatic operation available.

3. Worktable can rotate 90° or 360° (optional).

Multifunctional

It can do chamfer cut, straight cut, arc cut, arc cutting, shape cut, milling, drilling, line cut, and edging. With optional sensor, profiling function can be added.