Stone Water Jet Cutting Machine

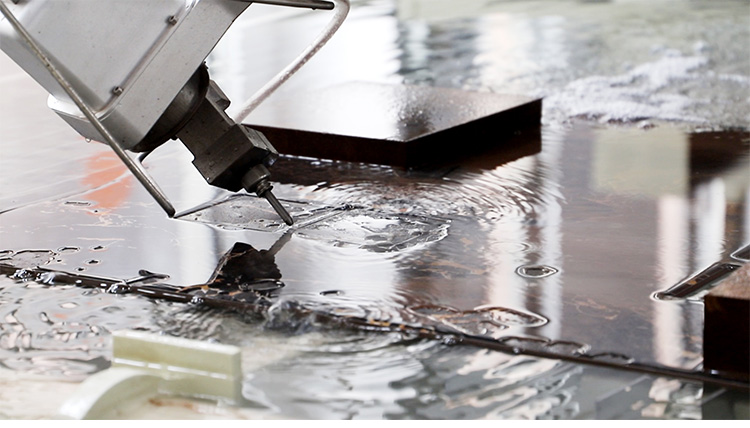

A stone water jet cutting machine is a sophisticated device that utilizes a high-pressure stream of water, often mixed with abrasive materials, to cut through stone and other hard materials. This method is renowned for its precision and ability to create intricate designs without compromising the integrity of the material.

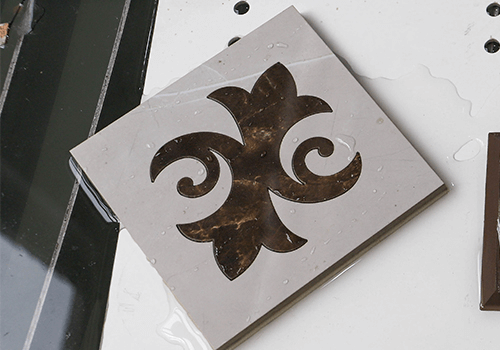

In the field of architecture, stone water jet cutting machines are invaluable for creating intricate designs and patterns in stone surfaces. From detailed facades to custom flooring, the precision of water jet cutting allows architects to bring their visions to life with unparalleled accuracy.

Stone water jet cutting machines can cut a wide range of materials, including granite, marble, slate, and even metals and glass.

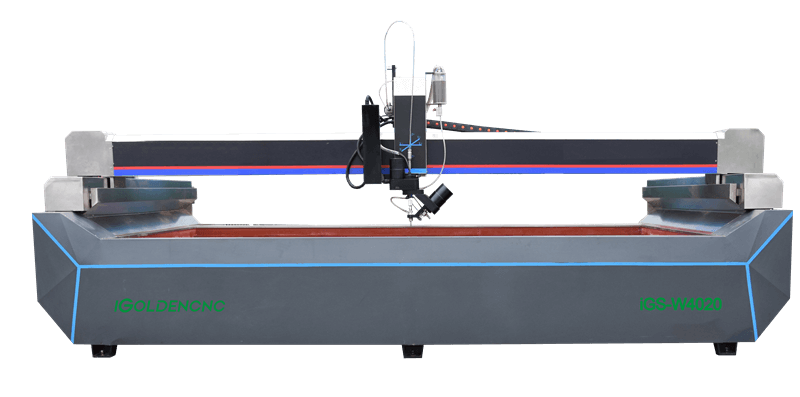

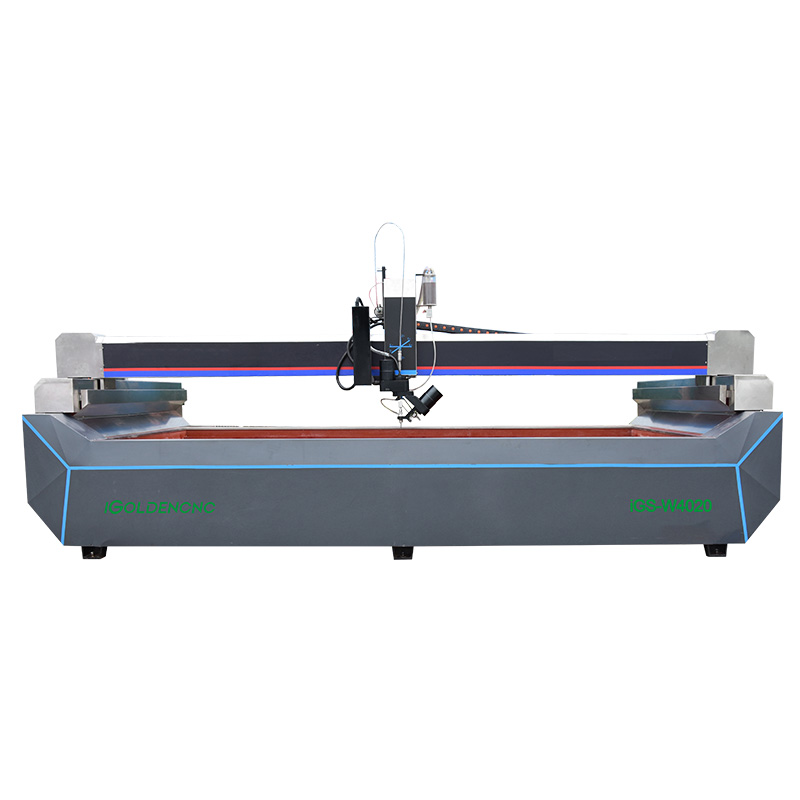

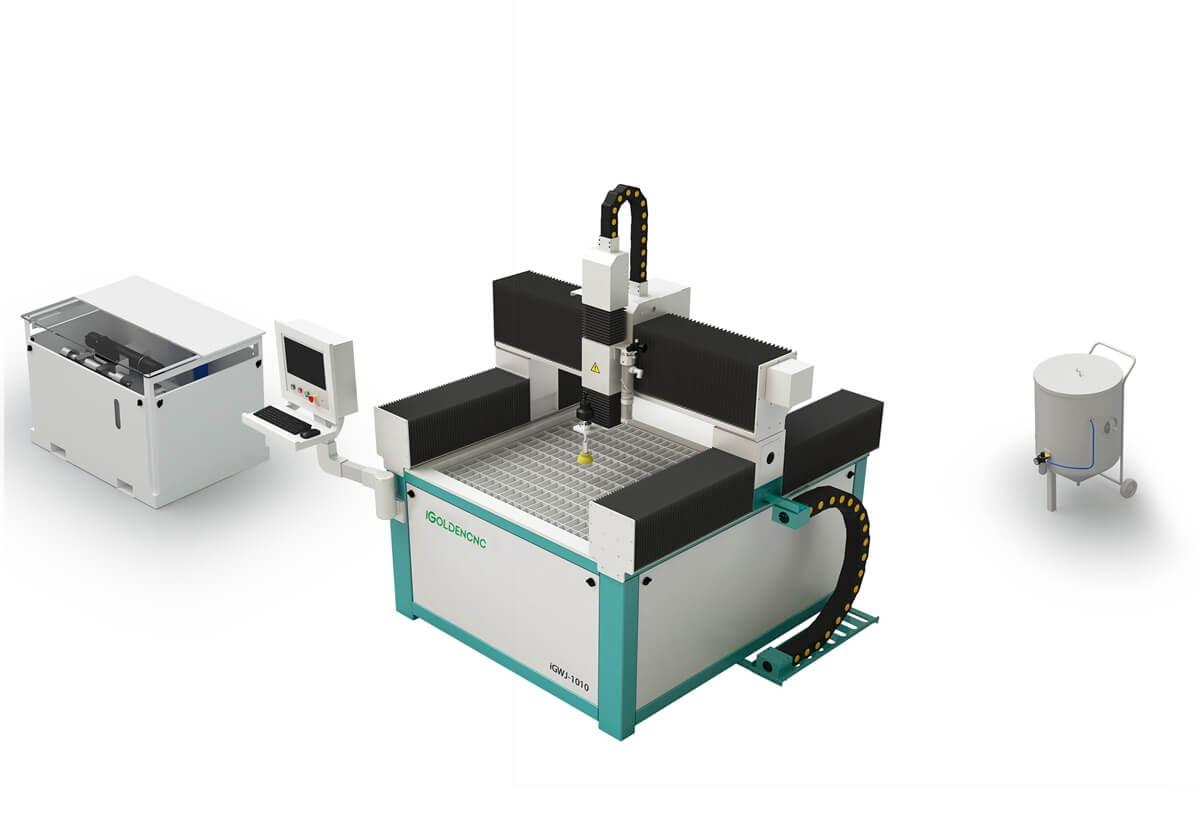

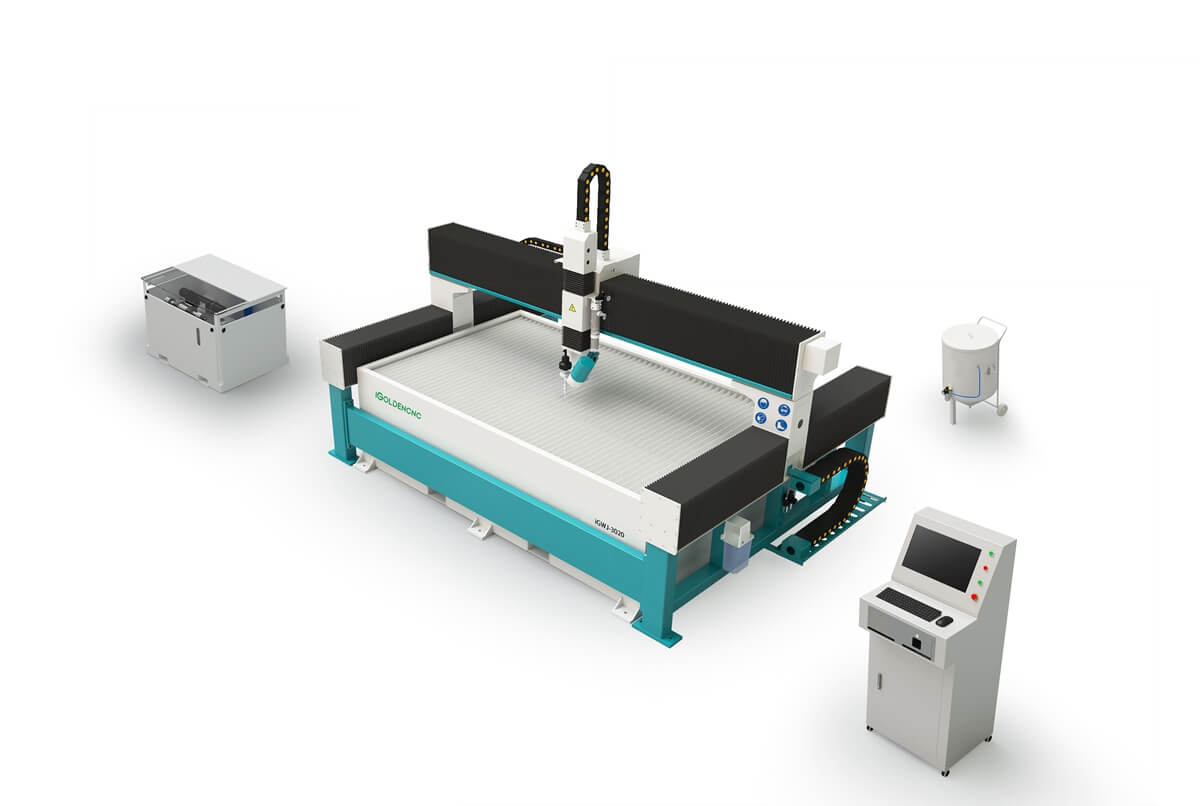

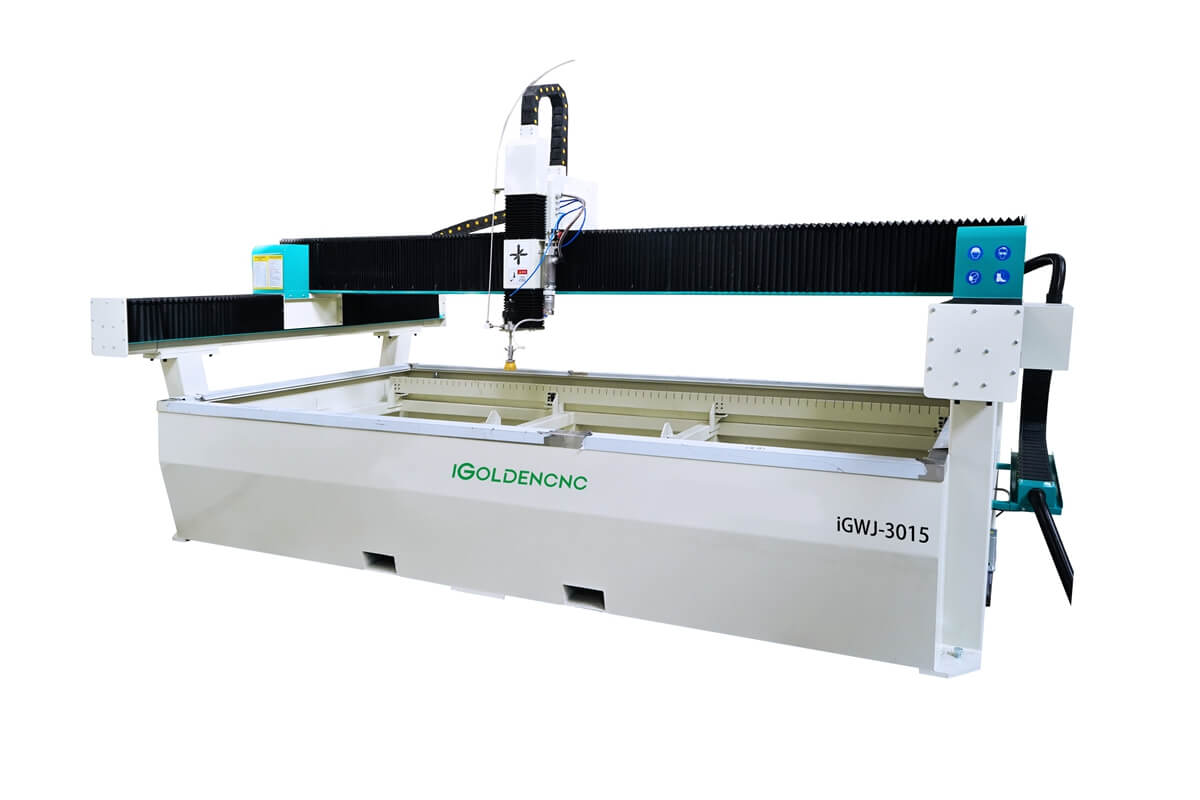

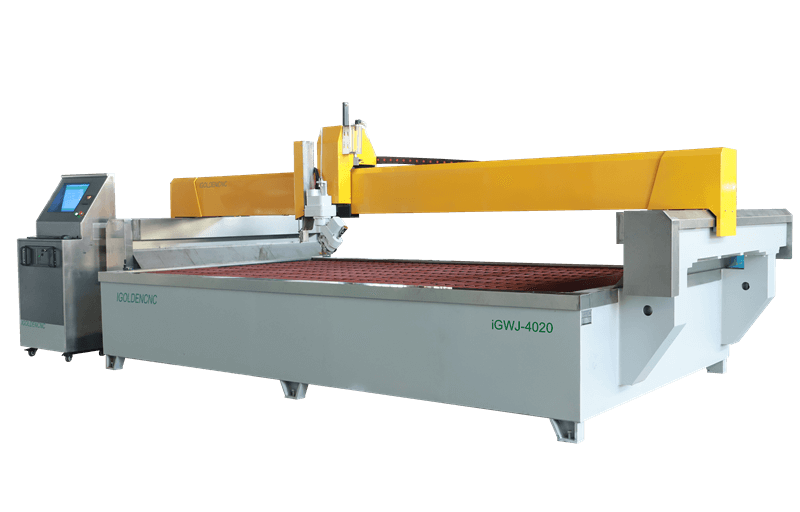

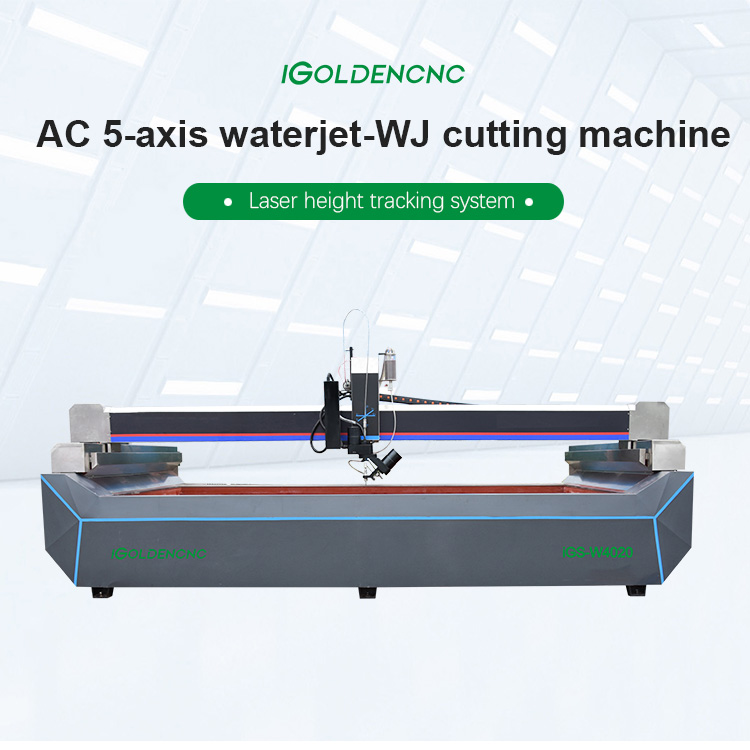

Water Jet Cutting Machine

Water Jet Cutting Machine Parameter

| Model | iGWJ-4020 |

| Platform size | 4200*2200mm |

| Cutting stroke | 4000*2000*150mm |

| A axis rotation Angle | ±60° |

| C axis rotation Angle | Infinite rotation |

| Max. cutting speed | 20m/min |

| Max. running speed | 50m/min |

| Cutting accuracy | ±0.1mm |

| Rotating accuracy | ±0.1° |

| Control accuracy | ±0.05mm |

| Repeated positioning accuracy | ±0.05mm |

| Platform | Steel platform |

| CNC garnet feeder | Taiwan FLOW sype |

| Motor servo | Japan Yaskawa servo motor |

| Guide rail | Taiwan HIWIN |

| Screw | Taiwan HIWIN |

| Gear rack | Imported rack and pinion from Switzerland |

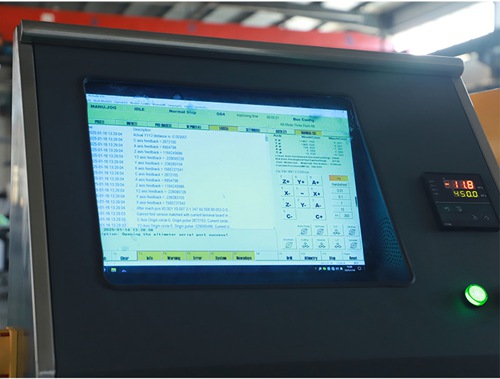

| Control system | WEIHONG |

| Electrical element | Schneider |

High pressure water cutting system mainly includes pressurization system, cutting platform, sand storage system, control system and auxiliary system.

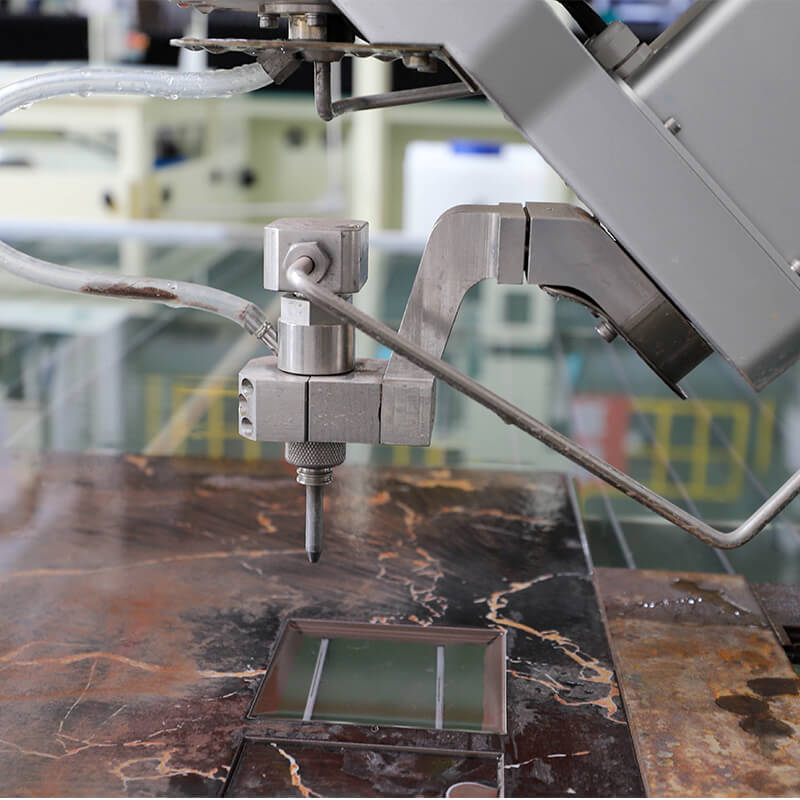

A/C Five-Axis Cutting Head

The 3D water jet cutter machine has five axes, 3 linear spindles and 2 rotating spindles. It has been designed for both pure 3D cut and 2D 1/2 cut (flat cut with bevel), without losing 2D (flat) cut functionality. Its design features offer great work possibilities.

Especially its infinite rotation in the C axis, which avoids the need to rewind with a consequent reduction in working times and a lower risk of reducing the cut quality. On the rotating frame of the C-axis, it is possible to connect the height adjustment and anti-collision control module.

Laser positioning

Dedicated water jet cutting software with graphic simulation running function, graphic input automatic programming function.

- Support for DXF files.

- Support forward and reverse processing functions.

- Uniform speed control function.

- Two modes of segmentation and smooth machining.

- Automatic processing with small arc speed.

- Coordinate recovery function after power off.

- Double lift speed parameter function.

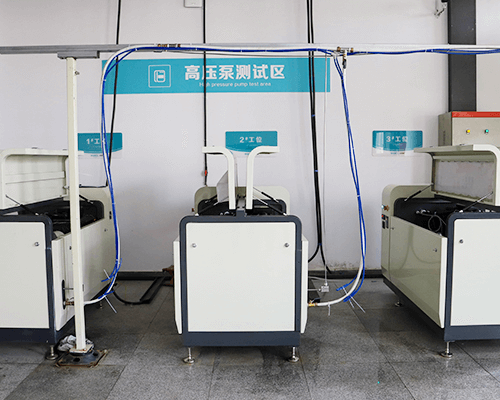

HP servo direct drive pump

Small weight: The total weight of direct drive pump is less than 600kg, and the movement is flexible. • Beautiful appearance: reasonable structure design, beautiful appearance, because the direct drive pump has no hydraulic system, so as to avoid the leakage of hydraulic oil (hydraulic seal will be damaged for a long time, resulting in hydraulic oil leakage), eliminate the pollution of oil stains to equipment.

Abrasive feeder

Provide sand storage function for water knife, and automatically transport sand to the sand bucket. It can improve the automation degree of equipment and reduce the labor intensity of operators. The high precision sensor alerts the operator when sand is needed and can be used for 8-10 hours. No electronic control, simple operation, reliable, maintenance-free.

Stone Water Jet Cutting Machine Industries & Applications

Industrial Manufacturing

In industrial settings, these machines are used to cut and shape components for machinery and equipment. The ability to cut through thick and hard materials with ease makes them a preferred choice in manufacturing processes.

Artistic Creations

Artists and sculptors utilize stone water jet cutting machines to craft intricate sculptures and art pieces. The precision and versatility of the technology allow for the creation of complex designs that would be challenging to achieve with traditional methods.

Custom Signage

For businesses and organizations, custom signage made from stone offers a unique and durable option. Water jet cutting machines enable the creation of detailed logos and text, providing a professional and lasting impression.

A cold cutting method offering unique benefits Metal cutting by the Abrasive Water Jet cutting process (AWJ) is a major area of application for water jet technology. Metals such as steel, stainless steel, titanium, aluminum or nonferrous metals.

Finely grained sand combined with the ultra-high-pressure water beam creates a powerful cutting tool, cutting up to 300 mm thick metal into any shape. This is a cold cutting process with fine cuts and very little additional work needed. A water jet system offers outstanding flexibility and is easily adjusted for each specific cutting requirement. Use one or several cutting heads.

Use 2D or 3D cutting and add some functional tools for added efficiency. Steel, stainless steel, Hastelloy, Hardox, Weldox, Inconel, titanium Aluminum Nonferrous metals

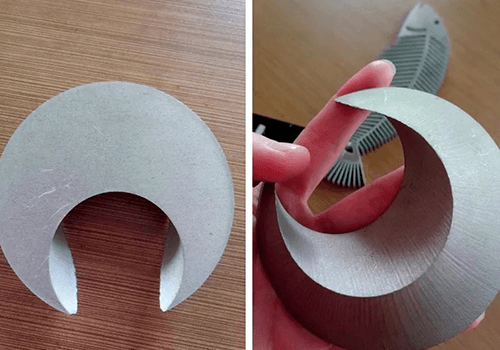

Cut any shape without cracking

Standard glass, composite glass, armored glass or Plexiglas®? For years, glass has been a frequent application area for water jet cutting. Diamonds may cut straight lines, but when it comes to curved shapes, water jet is a natural priority.

Glass is sensitive to cracking and requires careful handling. Use special cutting programs with low-pressure piercing and cutting tables adapted for smooth handling. In order to avoid chipped cutting edges, it is also important to use quality abrasives.

Let us find the best cutting solution for you.

For architectural design and artistic work

Water jet solutions cutting stone, tiles and other ceramic materials into different shapes are used all over the world.

Applications spans from comprehensive architectural structures and specific interior design elements to unique installations of public art. Using a water jet machine for free-cutting, you can easily transform most stone materials into almost any shape. The only limits will be set by your own creativity.

Let us find the best cutting solution for you.

Efficient production from small to large series

When cutting soft materials like rubber, plastics and foam, there is no need for abrasives. For soft materials, the pure water jet cutting process (PWJ) is a priority alternative. PWJ cuts rapidly with very narrow cuts of 0.1 mm When it comes to soft materials, the water jet technology brings benefits for both small- and large-scale production. There is no need for punching tools.

With simple CNC programming you can produce one single part quickly – and with a beam you can mount a large number of parallel cutting heads, thus cutting very large volumes simultaneously.

Less tool wear and almost any shape

There is an increased use for composite materials in many industries, yet there are few machine tools that are really suitable for processing these materials. One major challenge is tool wear. Usually, water jet cutting implies no extra tool wear and also offers the option to cut almost any shape. This is why this technology is widely considered the best alternative for composite processing.

The term composite comprises a wide range of materials with different characteristics:Kevlar, carbon fibre, glass fibre, non-woven materials, composite resins, etc. Therefore, what cutting process will turn out most efficient depends on the the material – Abrasive Water Jet cutting (AWJ), Fine Abrasive Water Jet cutting (FAWJ) or Pure Water Jet cutting (PWJ).

5 Axis Waterjet Cutting Machine

5 Axis Waterjet Cutting Advantage

Waterjet Cutting Machine for Sale

Custom Waterjet Cutting FAQ

The waterjet cutting process is versatile and can be accomplished in various ways. Most methods include an abrasive added into the water to help cut particles from the workpiece into a shape meeting precise specifications. Here is how the waterjet process works:

Determining Kerf Width

Kerf width refers to the material removed during the CNC waterjet process, typically 0.040 inches wide or less. The kerf size is a critical design factor and must be accounted for when determining the dimensions of the final product. The dimensions of the final part will only be accurate if the kerf is taken into consideration upfront.

Initial Waterjet Piercing

Piercing is another name for the first cut the waterjet cutter makes, and it starts the water jet cutting process, much like a plunge cut might initiate the beginning of a lathe process. The most common methods of piercing include stationary, linear, circular, and low pressure, depending on the material and the least amount of scrap produced.

Pressurizing the Water

The most often used method of pressurizing the water is a linear intensifier. Linear intensifier pumps use pressurized hydraulic oil at a pressure of 3000 psi. The low-pressure oil pushes against a piston with a face area twenty times larger than the high-pressure plunger that pushes against the water. Because the low-pressure pump is twenty times larger than the high-pressure pump, the pressure on the larger plunger is intensified twenty-fold, producing a water pressure of 60,000 psi.

Traveling Through the Tubing

The pressurized water moves through high-pressure tubing to the cutting head. The tubing is made from thermoplastic or stainless steel and has exceptional tensile strength, yield, and a smooth interior surface.

Waterjet Cutting Head

The pressurized water and garnet exit the cutting head’s orifice at nearly four times the speed of sound and can cut steel over one foot thick. As the water passes through the orifice of the cutting head, made of diamond, ruby, or sapphire with a .010” to .015” hole, its velocity increases to over 90,000 psi, directly affecting the waterjet cutting process.

The CNC water jet cutting process provides many advantages that are unmatchable with other cutting techniques. Some of these benefits are:

- No Heat-affected Zones: Heat-affected zones are caused by localized heating due to cutting friction. Water is a coolant in itself. Therefore, water jet cutting causes no heat-affected zones.

- Preserving Material Integrity: The material integrity remains intact due to the absence of heat zones. There are no burn marks on the material surface.

- Precision: The narrow stream of water results in a very high-precision cutting process. Water jet cutting has higher accuracy than alternative cutting methods.

- Edge Quality: Water jet cutting has a superior edge quality. This is the result of the material erosion that takes place on a particle level. Waterjet cut parts require no secondary finishing.

- No-contact Cutting: Water jet cutting does not require the contact of the tool with the workpiece. The high-pressure stream is enough to make the incision. This reduces the tool wear and calls for less frequent tool changes.

- Costs: Water jet cutting keeps the cost of operation manageable. Pure water jet cutting is a very cheap process. Abrasive water jet cutting has the cost of abrasive as the primary operational cost.

- Versatile: Waterjet cutter is the most versatile cutting option out there. It can handle all cutting materials regardless of their shape or form. This includes metals, non-metals, ceramics, composites, glass, paper, etc.

Abrasive waterjets are relatively new and have become candidates to replace traditional processes like drilling, profile milling, gear cutting, slitting, broaching, and sawing in various industries. The approximate price for a 2-axis abrasive system should be between $100,000 and $200,000, and a water-only CNC waterjet is usually in the $50,000 and $100,000 range.

There are other types of waterjet cutting machines, including 3D Printers, micro waterjets, and robotic waterjets. However, the style of any waterjet cutter is determined by its gantry design, which is the system that holds and supports the cutting head:

- Cantilever Gantry Machines: These have one arm over the table holding the cutting tool. They’re easy to use but can’t handle big pieces of material.

- Bridge Style Gantry Machines: These have a bar across the table, which the cutter moves along. They’re known for being stable and are good for cutting large things.

- Flying Bridge Gantry Machines: Similar to bridge style, but the whole top part moves with the cutter. They’re used for very accurate cutting on big machines.

- Articulated Arm Gantry Machines: These cutters have a bendable arm, like robot arms, to move the cutter. They’re best for detailed cuts or small spaces.

CNC waterjet cutting can have a tolerance as low as ± 0.002”. This makes CNC waterjet cutting one of the most accurate cutting methods. The exact tolerance of water jet cutting process depends on the particular material being cut. Maintaining the machine and doing the setup right can increase the precision of waterjet cutting.