Stone CNC Machine

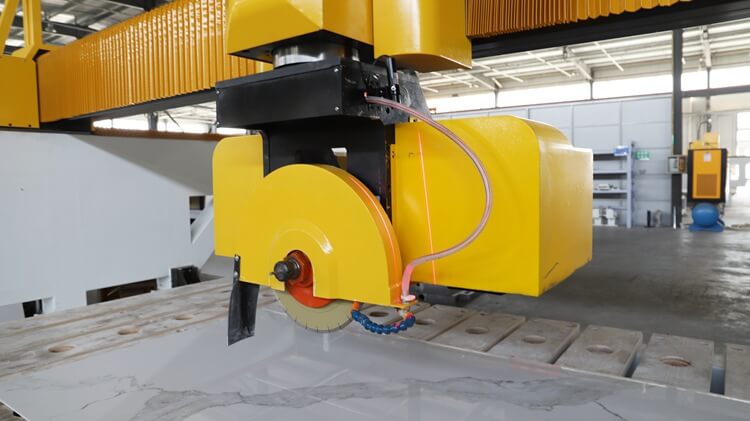

A stone CNC machine is a computer-controlled system designed to shape, polish, drill, or profile natural and engineered stone (granite, marble, quartz, limestone, and composite stones). Depending on configuration, these machines can cut complex shapes, drill holes, or perform multi-axis milling and sculpting with diamond tools and water cooling. The best-fit solution depends on your material mix, desired precision, and production volume.

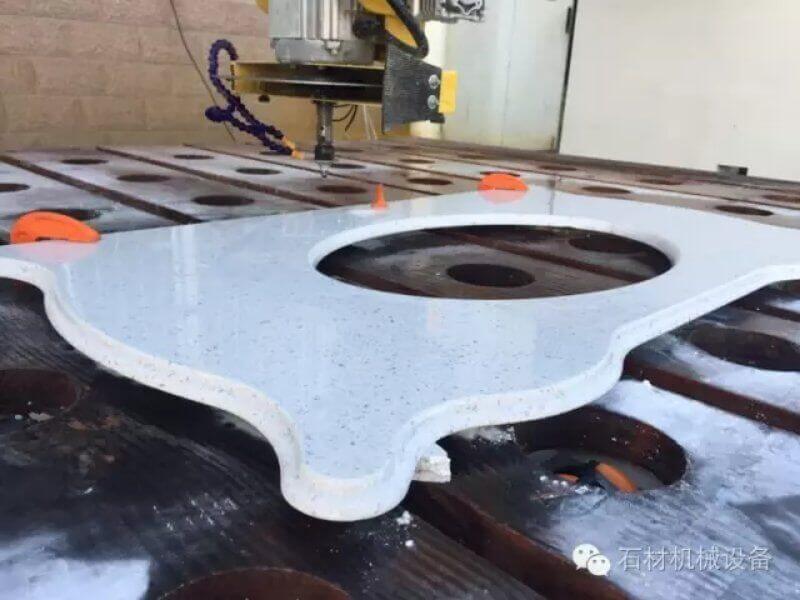

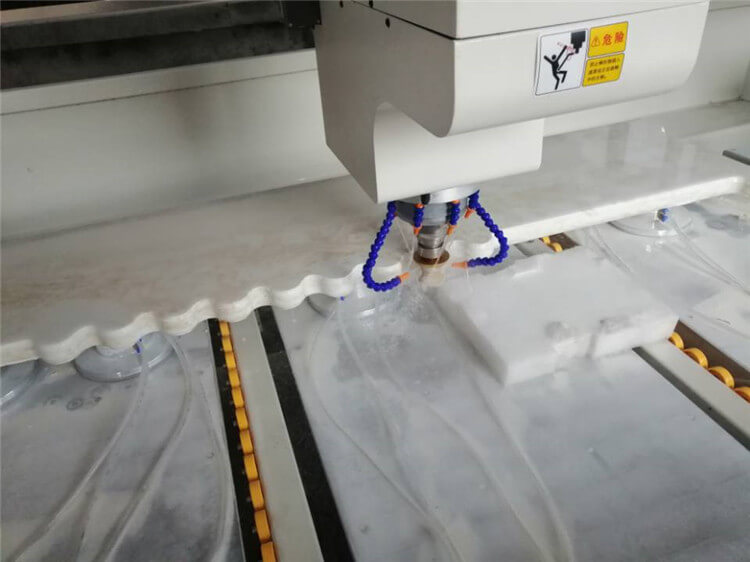

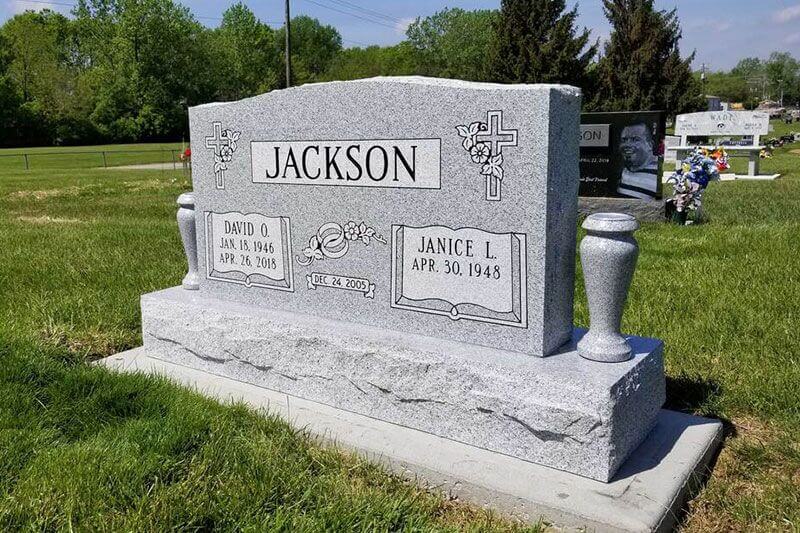

Stone Processing Samples

Stone CNC Machine Buyer Guide

Looking to invest in a reliable Stone CNC Machine for professional stone fabrication? Whether you need a 5 Axis Bridge Cutting Machine for complex countertop designs, 3D sculptures, and architectural stonework, or a versatile Stone Cutting Machine for efficient marble, granite, and quartz processing, the right equipment can transform your production. These machines are widely used for tombstone engraving, kitchen countertops, bathroom vanity tops, floor tiles, wall panels, and decorative stone art. Built with high-rigidity structures, powerful spindles, and advanced CAD/CAM compatibility, they ensure precision, durability, and long-term efficiency for workshops, stone factories, and custom art studios.