CNC Wood Nesting and Cutting Solutions

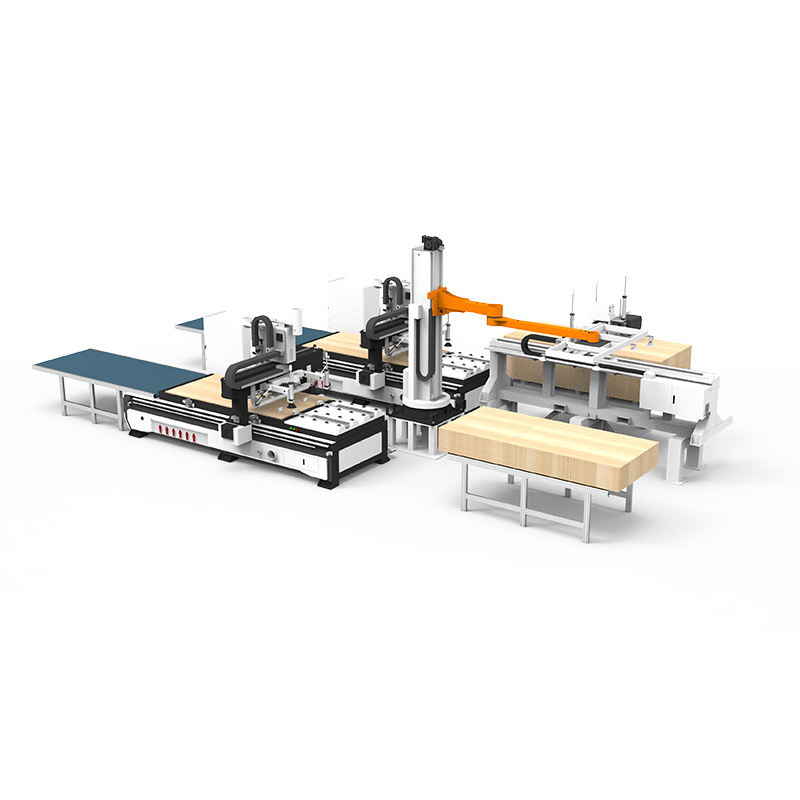

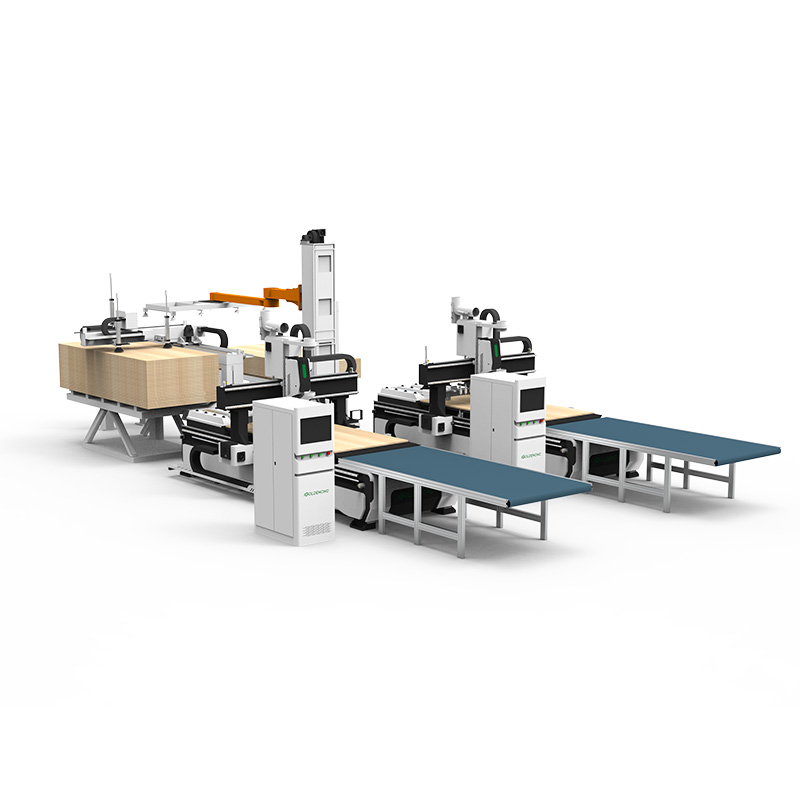

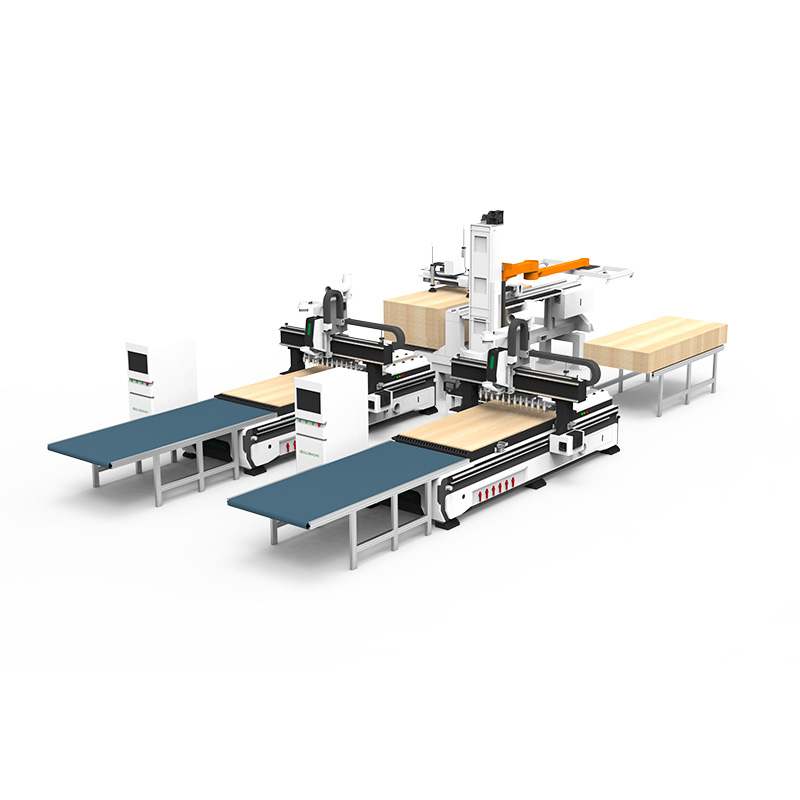

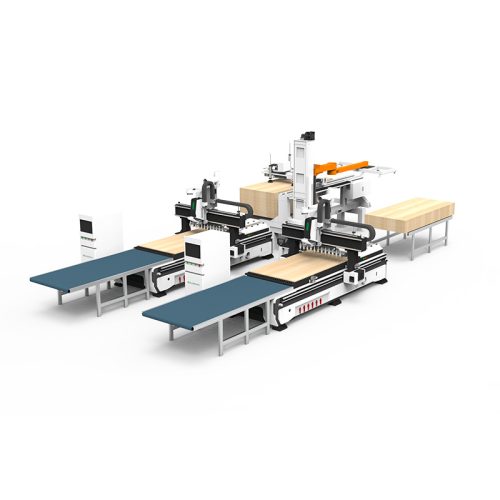

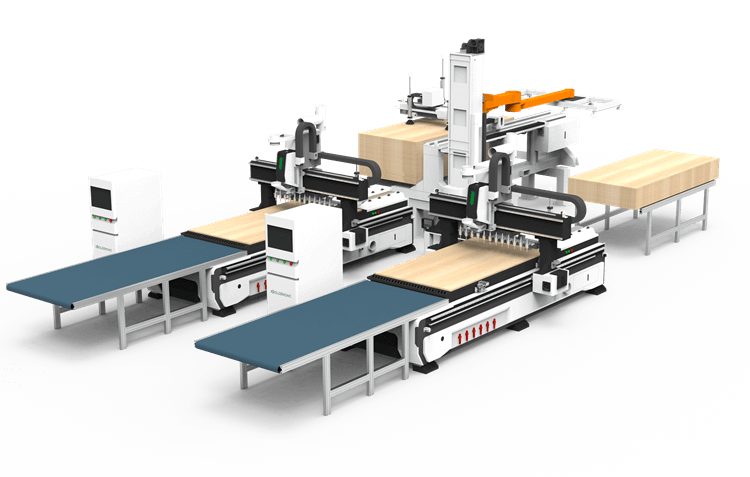

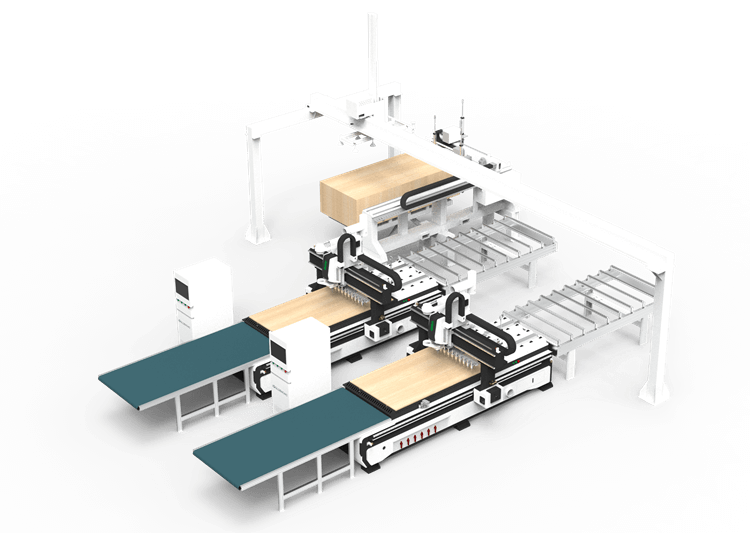

A One-for-Two Nesting Panel Furniture Automatic Production Line is an advanced, integrated manufacturing system used in the panel furniture industry (like wardrobes, cabinets, and office furniture). It combines automation, CNC machining, intelligent nesting, and material handling to dramatically boost productivity and reduce labor requirements.

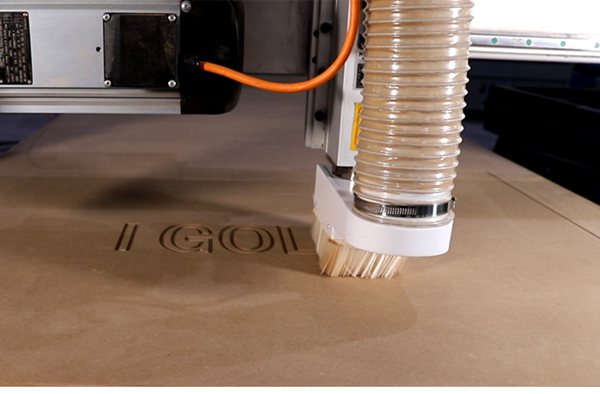

A CNC wood nesting and cutting machine represents the pinnacle of automated woodworking technology. Unlike traditional CNC routers that simply cut individual pieces, nesting machines integrate intelligent software that optimizes panel layouts, automatically positions parts for maximum material utilization, and executes complex cutting, drilling, and grooving operations—all in a single, seamless workflow.

The term “nesting” refers to the machine’s ability to arrange multiple furniture components on a single sheet of material like a puzzle, minimizing waste and maximizing every square inch of expensive plywood, MDF, or particleboard. This sophisticated software integration transforms raw design files into production-ready toolpaths that guide the cutting head with micron-level precision.

CNC Furniture Making Video

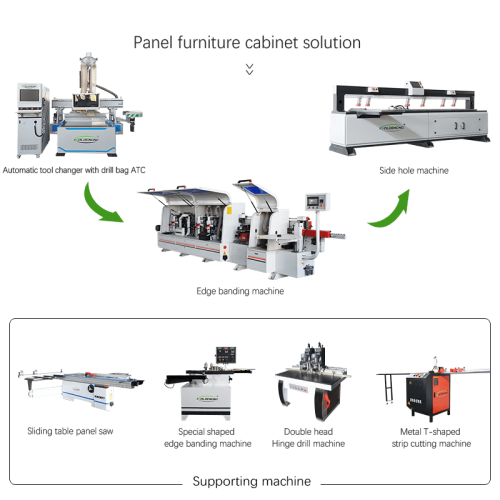

Processing process

The lift below the elevated labeler can hold 60 sheets → The central control software sends the label information to the labeling machine →After the automatic labeling machine has finished labeling, the robot will distribute it to the No. 1 and No. 2 cutting machines. →The processing program is sent by the central control software to the corresponding cutting machine for cutting.→If the cutting machine has not completed its work, the robot will place the grabbed sheet in the labeling buffer area, and the labeling machine will continue labeling until all processed sheets are completed.

CNC Wood Nesting and Cutting Production Line

| Model | iGC-RL-1T2 |

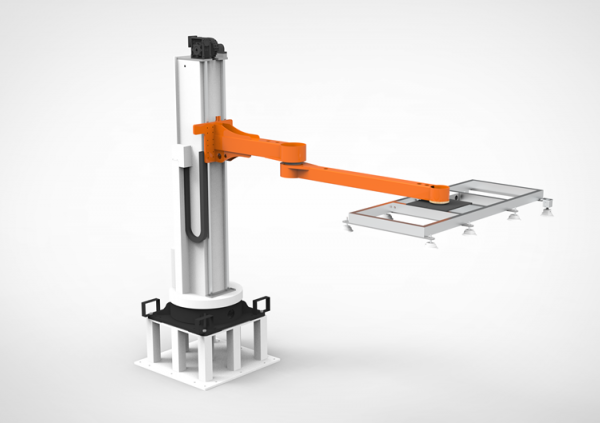

| Robot | |

| Number of axes | 4-axis |

| Arm length | 2.9m |

| Rotation | Chassis rotation 360° |

| Number of suction cups | 8 |

| Suction cup load weight | Max. 100kg |

| Height | 3.8m |

| CNC cutting machine | |

| Working area(X,Y,Z) | 1300*2500*250mm(Customizable) |

| Max. empty line speed | 60000mm/min |

| Max. operating speed | 30000mm/min |

| Spindle power | 9.0kw Air-cooled tool-changing spindle |

| Spindle speed | 24000rpm |

| Positioning accuracy | 0.03mm |

| X,Y axis transmission | Rack |

| Z-axis drive | Ball Screw |

| Repeat positioning accuracy | 0.02mm |

| Command language | G Code |

| Operating voltage | AC220V/380V, 50Hz |

Automatic Tool Change Technology

Our machines feature advanced automatic tool change (ATC) systems with linear tool magazines holding 8-12 different cutting tools. During operation, the machine automatically selects and swaps tools based on programmed requirements—switching from cutting bits to drilling bits to grooving tools without manual intervention.

The tool magazine accommodates various tool types: straight cutting bits for panel sizing, spiral bits for smooth edge finishing, drilling bits in multiple diameters for hardware installation, and specialized tools for decorative routing. This versatility enables the machine to handle complete furniture manufacturing processes without external equipment.

Heightening labeling machine

The heightened labeling machine is equipped with an intelligent lifting storage platform, which supports the continuous buffer supply of 60 sheets of plate materials, breaking through the traditional single-time loading limitation.

Intelligent Vacuum Holding Systems

Securing workpieces during cutting presents unique challenges. Traditional clamping systems limit cutting areas and require time-consuming setup. Our CNC nesting machines employ powerful vacuum systems that hold materials firmly across the entire table surface using negative pressure.

The vacuum system also accommodates materials of varying densities and surface finishes. Whether processing solid hardwood, engineered panels, or plastic laminates, the system maintains secure positioning throughout the cutting cycle, preventing movement that would compromise accuracy.

Dual CNC Nesting Machines

Maximizing machine utilization requires eliminating idle time. Our advanced models feature double platform designs where one work surface undergoes machining while operators load materials on the second surface. When cutting completes, the platforms automatically exchange positions—the newly loaded material moves into the cutting area while processed parts move to the unloading zone.

The double platform system particularly benefits high-volume production environments where machine utilization directly impacts profitability. By maintaining continuous operation throughout production shifts, these systems maximize return on investment and accelerate order completion.

Key Features of One Loading/Unloading System Feeding Two Cnc Nesting Machines

- Twice the Output: Two machines share one loading/unloading line — one operator can control both.

- Full Automation: Loading, cutting, labeling, and unloading without manual handling.

- Consistent Precision: CNC control ensures every piece is identical.

- Reduced Labor Cost: Typically managed by only 1–2 operators.

- Optimized Material Usage: Automatic nesting software maximizes board utilization.

- Scalable: Can integrate with ERP or MES systems for smart factory operations.

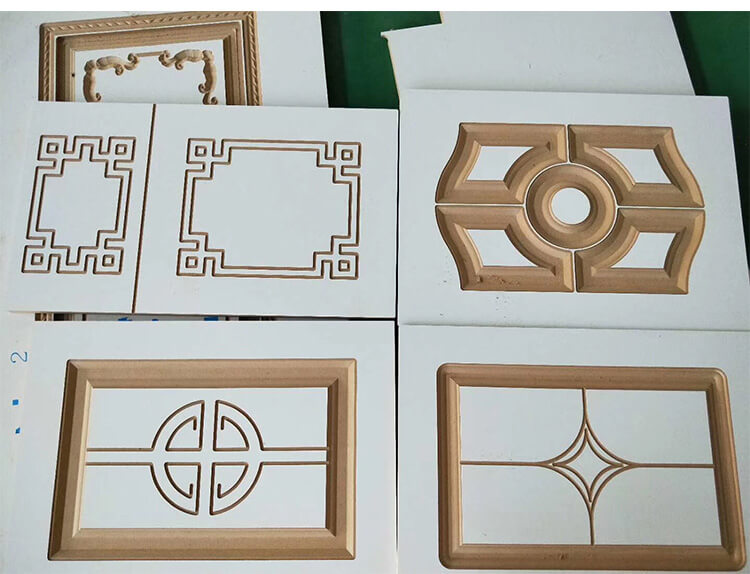

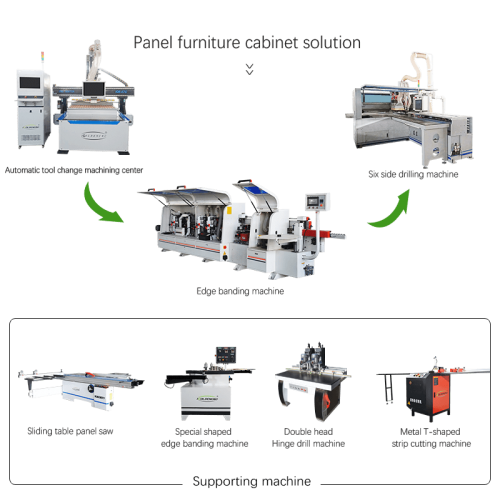

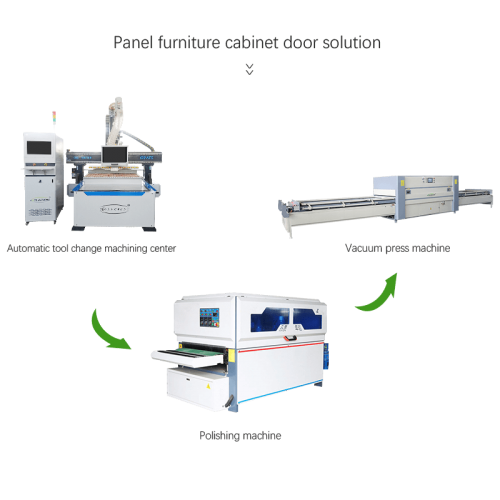

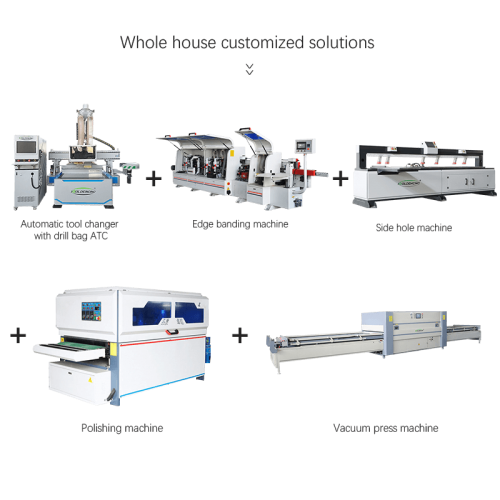

Panel Furniture Production Line Application

-

Custom panel furniture production Wardrobes, cabinets, shelves, and modular furniture

-

Office and kitchen furniture Closet door panels and drawer components

It’s especially suited for smart factories, batch customization, and intelligent furniture manufacturing workshops.

Contact Us Today to Get Price!

IGOLDENCNC wood furniture production line is an automated manufacturing system that can produce wooden products such as wooden furniture or cabinets more accurately and efficiently. The production line uses advanced CNC technology and integrates CNC machines at each processing stage to ensure high precision, high productivity and high compatibility. Whether it is furniture products such as cabinets, tables, chairs or wardrobes, they can all be mass-produced and standardized using this production line to meet the diverse needs of the market.

1. Control System: The integrated CNC control system and user interface are the heart of the entire production line. With a straightforward style, the operator can conveniently enter processing criteria and keep an eye on the production process to ensure accurate control at every stage.

2. Automatic Loading Platform: The automatic loading can automatically grab wooden boards with a mechanical arm or gantry type vacuum suction cup and place them in an orderly manner on the conveyor belt.

3. Feeding Conveyor: As the starting point of the CNC wood furniture production line, the feeding conveyor is responsible for stably and accurately feeding raw materials (such as wooden boards) into the processing system, ensuring the subsequent processes.

4. Automatic Labeling System: This system labels each finished board to ensure product traceability throughout the production process, as well as facilitating subsequent assembly and sorting.

5. Two-Side Drilling Machine: The drilling machine accurately drills holes and grooving on the front and back surface of the wooden board according to the design requirements, ensuring that the furniture parts will perfectly connect when assembled, and also meeting the needs of the next step of processing.

6. CNC Nesting Machine: This CNC wood furniture production line is equipped with an advanced CNC nesting machine. The cnc router machine can precisely cut the wood panels into the required shapes and sizes according to a predetermined program. Both straight line cutting and complex curve cutting can be completed quickly.

7. Edge banding machine (optional): The edge banding machine can apply a protective and decorative finish to the edges of the boards, which not only improves the durability and appearance of the product, but also meets the processing needs of high-end furniture.

| Configuration | Estimated Price (USD) |

|---|---|

| Standard Line (Dual 1325 CNC + Loader) | $55,000 – $70,000 |

| High-End ATC Model (Dual 2040 + Label + Conveyor) | $75,000 – $110,000 |

| Smart Factory Integration (MES + Edge Banding) | $120,000 – $150,000+ |

-

Automatic Loading

The system picks up raw boards and places them on the CNC table. -

Label Printing (Optional)

Barcode labels are automatically printed and applied for part identification. -

Nesting and Cutting

The nesting CNC router cuts the panel into parts according to the CAD design file. -

Automatic Unloading

Finished panels are unloaded and stacked neatly. -

Switching Process

While one machine unloads, the other starts processing — ensuring no downtime. -

Next Stage Integration

The processed panels can go directly to edge banding, drilling, or assembly lines.