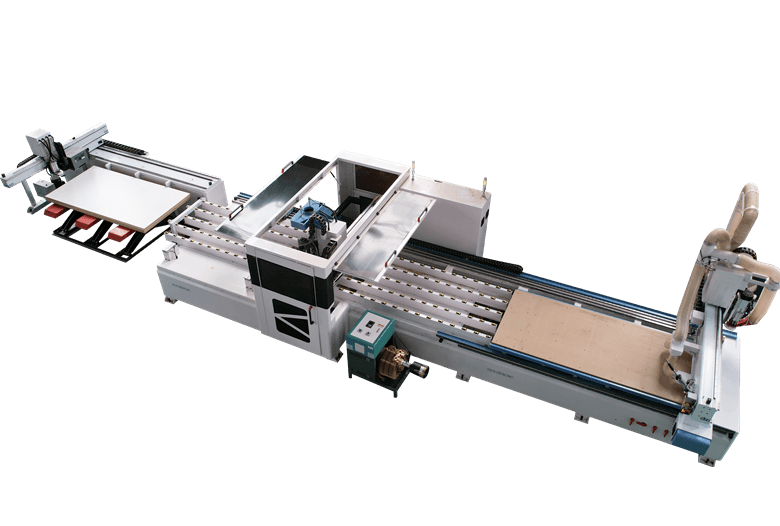

Woodworking Cutting and Drilling CNC Machining Center

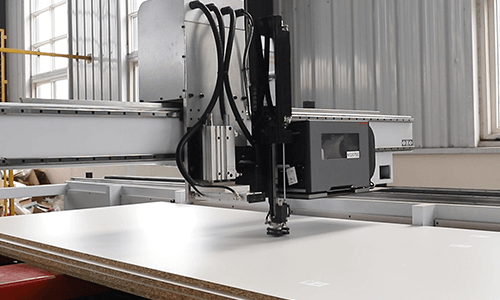

CNC nesting machining centres for cutting and drilling are high-performance and reliable machines, specifically designed for manufacturers who need to produce in batches or in single orders. Precision in machining even the most difficult workpieces, high speeds and maximum flexibility are guaranteed by this all-in-one technology, increasingly functional and intelligent.

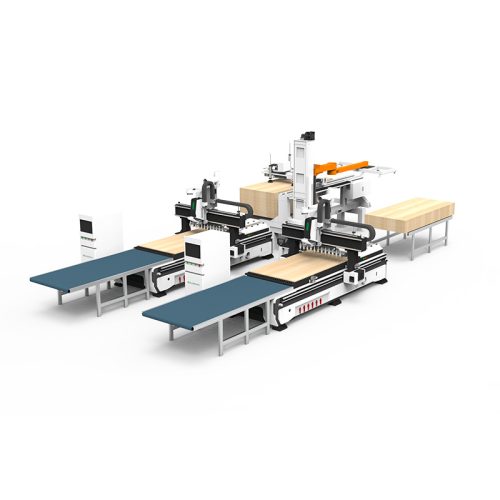

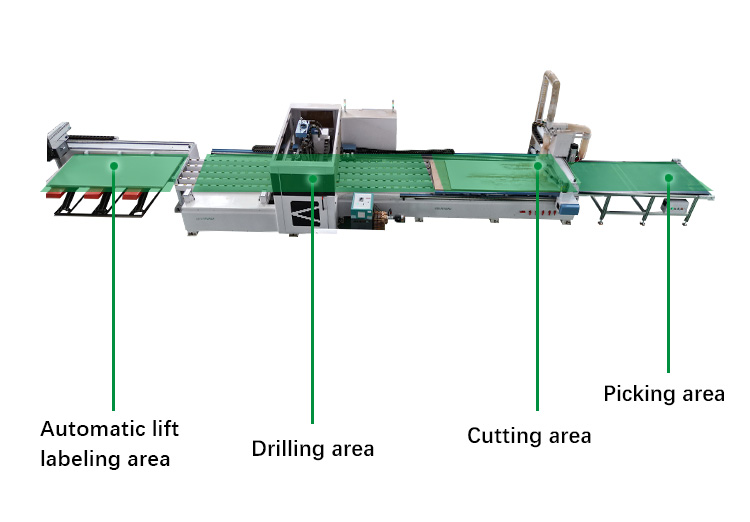

The machining center is equipped with saw blade spindle, linear tool changer, and automatic loading and unloading platform. With automatic labeling system, it can help improve efficiency and reduce labor costs.

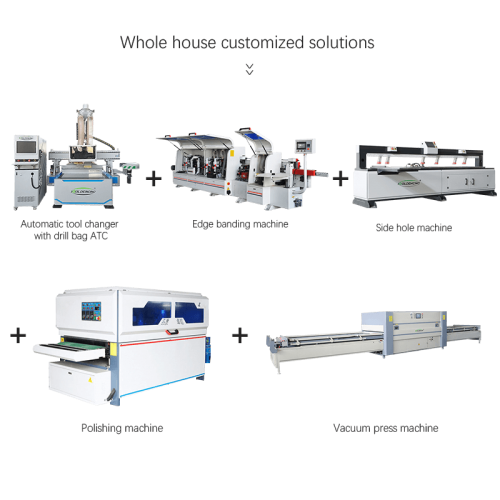

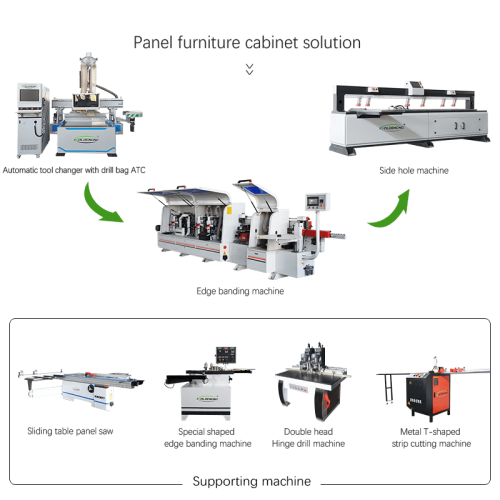

Nesting CNC machine is a type of panel furniture production line, which is a smart CNC solution for customized furniture production like panel furniture making, cabinet door making, closet door making, home door making, wardrobe making, home decoration making, cabinets making, home furniture making, shop and office furniture making.

IGOLDENCNC offers a wide range of CNC machining centres, responding to the evolving requirements of the furniture and building industry. Quality, technology, productivity and flexibility are the characteristics of cnc woodworking CNC machining center, in order to guarantee high production standards in short times.

CNC Cutting and Drilling Machining Center

CNC Drilling and Cutting Machining Center Parameter

| Control system | Taiwan SYNTEC system |

| Servo | INOVANCE 1.5KW servo |

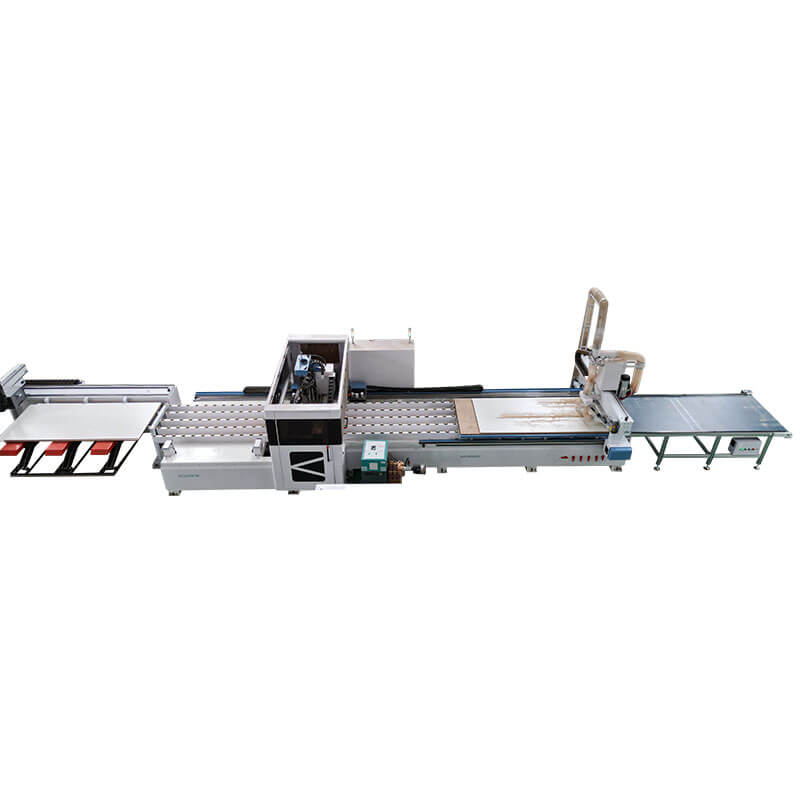

| Processing Mode | Automatic labeling + feeding + double-sided punching + high-speed cutting + pushing |

| Punch unit | Double drill work at the same time |

| Slotted unit | Slot both top and bottom |

| Label the material | Independent automatic induction rotary labeling + automatic feeding |

| Clamp forceps | Double independent clamp |

| Reducer | Japan SHIMPO |

| Guide rail | Taiwan HIWIN |

| Rack | High precision grinding rack |

| Drill bag | HQD high torque drill pack |

| Spindle | HQD high speed spindle |

| Inverter | Fuling |

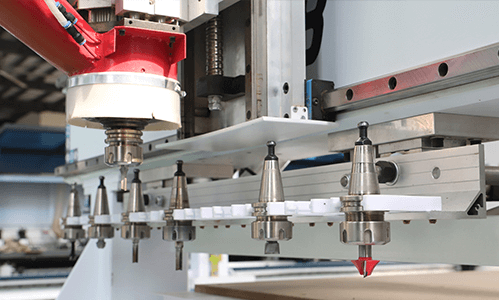

| Magazine tool | 16 knife in-line knife library |

| Vacuum pump | 6.0KW variable-frequency vacuum pump |

| Dust collector | 7.5KW double vacuum cleaner |

| Blanking platform | Automatic sensing platform |

| Whole length | 14m |

| Total weight | 5T |

Smart Wood CNC Cutting Drilling Machine Advantage

- Improve production efficiency: the upper and lower drilling of the whole plate is faster and more efficient than the piece-by-piece processing of the smaller allegro;

- Reduce the damage of the plate in the production process: while building the production process, it reduces the transmission and handling of the plate in the production process, effectively reducing the damage of the plate;

- High degree of automation: compared with the traditional stand-alone equipment, the manual only needs to pick up the board and turn to the edge banding machine, which greatly improves the degree of automation in the production process;

- Low failure rate, easy to operate: compared with traditional automated production lines, easier to operate, lower failure rate;

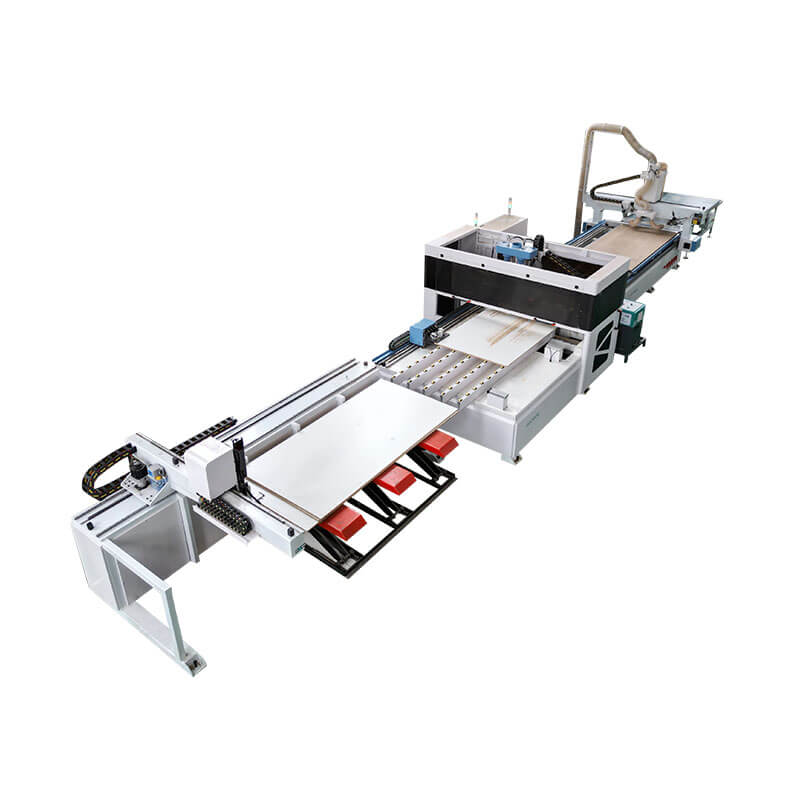

Automatic labeling

Completely replace the dependence on manual labeling, paste the label well before processing, truly realize intelligence, save labor, save time, and effectively avoid manual labeling errors;

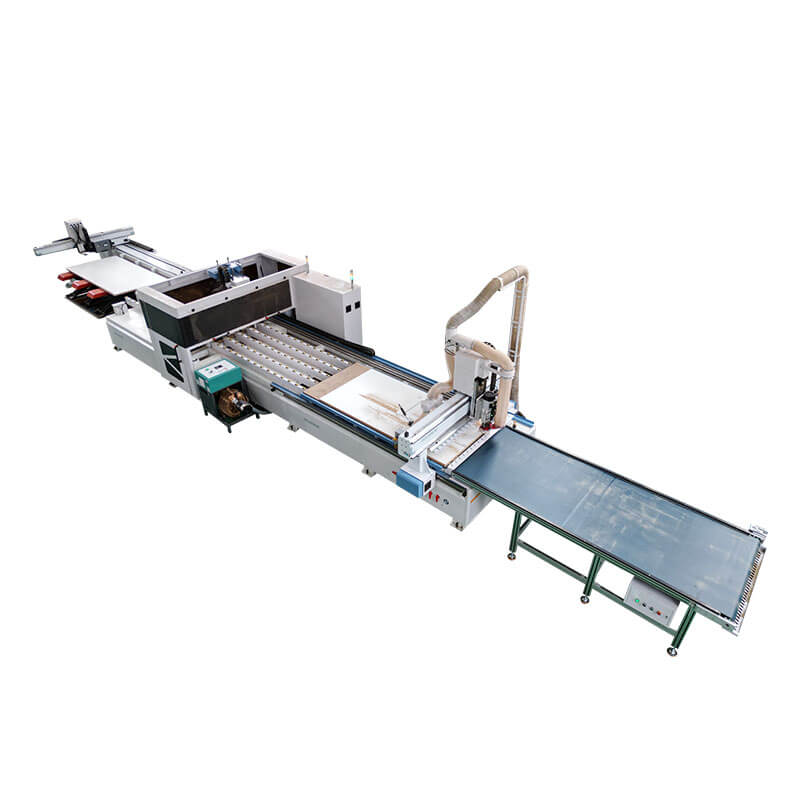

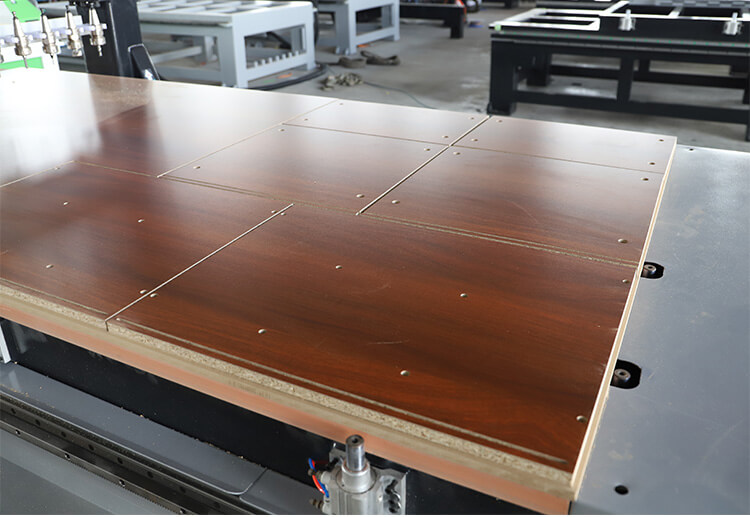

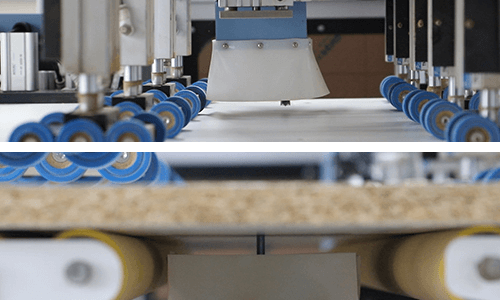

Bed integrated design

Double side drilling unit and cutting unit integrated design, the whole plate and then the double side drilling unit drilling, directly and automatically transported to the cutting unit, higher accuracy; More efficient;

Double drill bag

Drill holes and grooves on both sides of the plate.

HQD tool change spindle

9KW spindle + large capacity tool library, can meet a variety of processes.

Applications of CNC Machining Centers in Woodworking

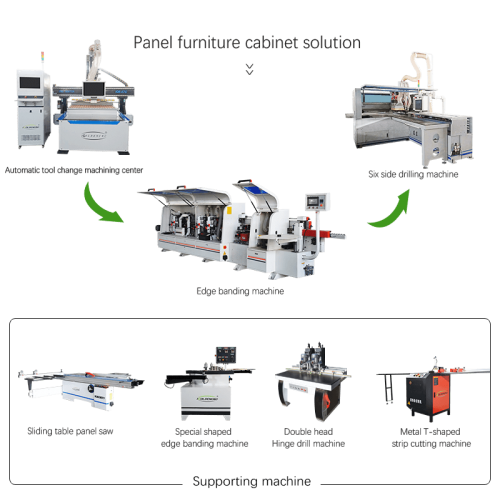

Furniture Making

CNC machining centers are widely used in furniture making to create precise and intricate designs. From cutting and shaping components to drilling holes for assembly, these machines streamline the production process and ensure high-quality results.

Cabinetry

In cabinetry, CNC machining centers excel at producing consistent and accurate cuts for cabinet parts. The ability to program complex designs and patterns allows for the creation of custom cabinets with intricate details and precise dimensions.

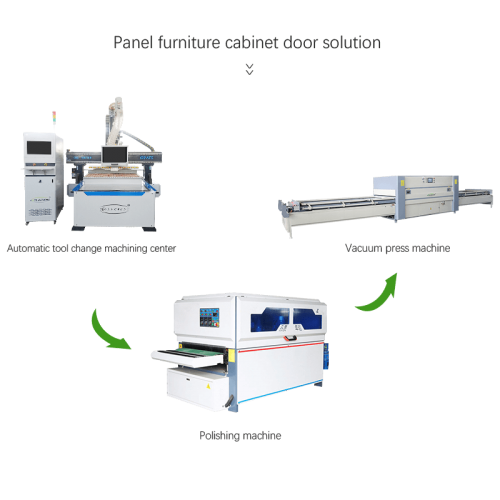

Custom Woodworking

For custom woodworking projects, CNC machining centers offer unparalleled flexibility. Whether it’s creating unique decorative elements or producing bespoke furniture pieces, these machines can bring even the most intricate designs to life with precision and efficiency.

CNC Drilling and Cutting Integrated Machine for Sale

A CNC machining center is used for various woodworking tasks, including cutting, drilling, shaping, and carving. It offers precision, efficiency, and versatility, making it ideal for projects such as furniture making, cabinetry, and custom woodworking.

CNC machining centers automate complex operations, reducing production time and minimizing errors. Features such as automated tool changes and material handling further enhance efficiency, allowing woodworkers to complete projects faster.

When choosing a CNC machining center, consider your specific woodworking needs, the machine’s capabilities, the software used, and the manufacturer’s support. Evaluate factors such as cutting speed, spindle power, tool capacity, and worktable size to ensure the machine meets your requirements.

Future trends in CNC machining for woodworking include the integration of automation and robotics, the ability to work with advanced materials, and the incorporation of smart technology such as IoT and AI. These advancements enhance efficiency, precision, and versatility in woodworking projects.