CNC Glass/Stone Cutting Centre Edge Grinding/Polishing, Milling, Grooving, Routing, Dilling Machine

CNC glass machining center is a combination of glass edge grinding, chamfering, polishing, drilling, and milling. Specially designed for grinding from the inside or outside, the equipment features simple operation and applies to machining automotive glass, home appliance glass, furniture glass, shower room glass and mirrors of all descriptions. It is aimed at automating production and thus improving the competitiveness of enterprises.

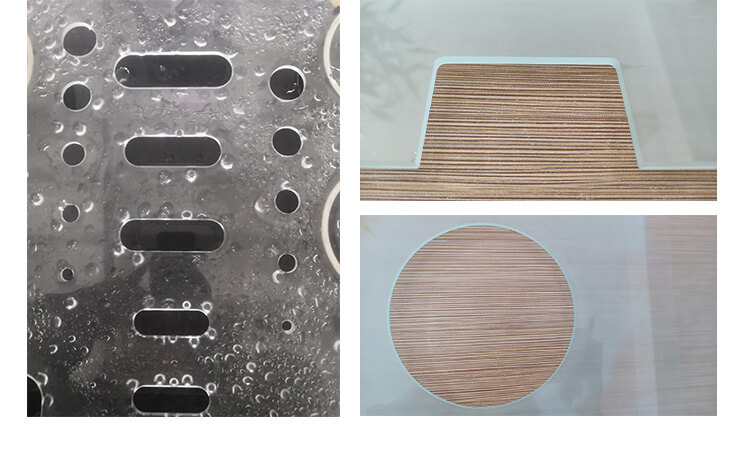

With integrative function drilling cutting milling grinding polishing and engraving,once time finished, no need to change the cutter, which effectively avoids glass scratches and dimensional errors caused by repeated positioning.

Suitable for minimalist style cabinets and closet alass and slate door handle milling, cabinet glass and slate countertops sink stove hole milling and opening, glass shower room, glass sliding door clip, hinge hole, Milling type of keyhole.

CNC Glass Cutting Centre Edge Grinding/Polishing, Dilling Machine

11KW water-cooled main shaft

The use of powerful high-power spindle, cutting force, high efficiency, water circulation cooling, good heat dissipation, smooth and fast operation.

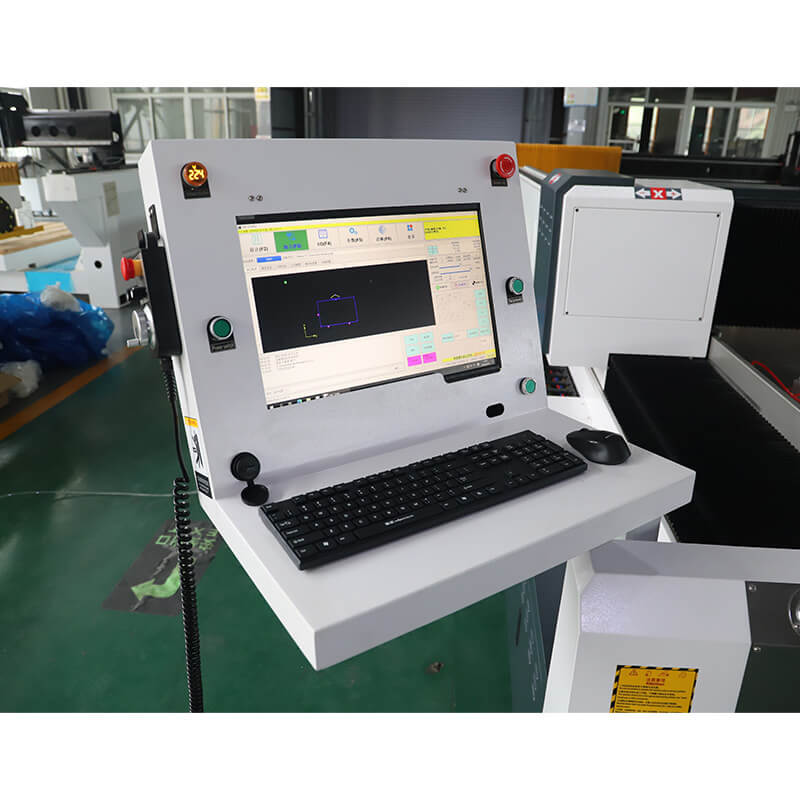

Professional glass operating system

Professional control system, fast and smooth processing, can be cut, drilling, hinge, shaped cutting, edging, glass polishing and other processing.

In-line tool changing tool library

The standard is equipped with 6 knives, which can be automatically changed according to different processes to improve processing efficiency.

16 suction cups

The suction cup is made of silicone ring and nylon column table, high vacuum, large suction.

CNC Glass Cutting Edge Grinding/Polishing, Dilling Machine

| Technical indicators | parameter |

| Model | iGR-MC3015 |

| Work travel | 3000*1500*350mm |

| Spindle | 11kw |

| Wheel Diameter | 50-160mm |

| Rotating mode | Three-axis full screw transmission |

| Cooling System | CW3000 Chiller |

| Positioning Precision | ±0.05 |

| Repeatability | ±0.03 |

| Finished product precision | ±0.2mm |

| Servo Motor | Taiwan Delta-1.3KW |

| Converter | Taiwan Delta-7.5KW |

| Lead rail | Taiwan TBI |

| CNC System | Special glass system |

| Lubrication system | High-end automatic oil filling pump for machine tools |

| Vacuum pump | 7.5kw water vacuum pump |

| Max processing Size | 2800*1200mm |

| Min processing Size | 150*150mm |

| Machining thickness | 2-19mm |

| X,Y axis Speed | 20000mm/min |

| Z axis speed | 5000mm/min |

| Max cut feed speeds | 6000-12000mm/min |

| Electrical appliance | French Schneider/Omron |

| Knife vault | Six Knives |

| Sucker 16 sets | silicone ring,nylon column |

| Position | 6 sets |

| Max Loading | 300kg |

| Machine Weight | 5200kg |

| Power Consumption | 15KW |

| FloorSpace(L*W*HW) | 5300*2200*1800mm |

Benefits of CNC Glass Cutting Centre

Cnc Edging Polishing Milling Glass Cutting Machine Application

Cnc Edging Polishing Milling Glass Cutting Machine ,Drilling, Milling, Internal and External grinding and polishing, Writing, Shaped Notching, Engraving on glass、Marable, stone, quartz and so on.

Architectural Glass

CNC glass milling and drilling machines are widely used in the architectural industry to fabricate glass panels for windows, doors, facades, and other building elements. The machines can mill intricate patterns and drill precise holes for hardware installation, such as hinges, handles, and locks.

Automotive Glass

In the automotive industry, CNC glass milling and drilling machines are used to fabricate windshields, side windows, and rear windows.

CNC Glass Cutting Edge Grinding/Polishing, Dilling Machine FAQ

CNC machines can fabricate a wide range of glass doors, including sliding glass doors, frameless glass doors, shower doors, glass partition doors, and custom glass doors. Ensure that the machine you choose is compatible with the type of glass door you’ll be fabricating.

Our advanced ATC CNC machine is designed for precision processing of mirror glass, offering grinding, polishing, drilling, milling, beveling, and edging capabilities. It features an Automatic Tool Changer (ATC) for seamless operation and increased efficiency. With high-speed spindles, accurate positioning, and user-friendly controls, this machine ensures superior edge quality and intricate designs. Ideal for manufacturers seeking reliable performance and versatility in glass fabrication.

Automatic Tool Changer (ATC): Seamlessly switch between various tools for different processes, enhancing productivity and reducing downtime.

High Precision Processing: Achieve excellent accuracy and smooth finishes with advanced CNC control for consistent results on every piece.

Multi-Functionality: Capable of grinding, polishing, drilling, milling, beveling, and edging, all in one machine, saving space and investment in multiple machines.

Robust Construction: Built with a heavy-duty frame and high-quality components, ensuring long-term stability and reduced vibrations for superior surface quality.

User-Friendly Interface: Intuitive CNC control panel with easy-to-program software, allowing operators of all skill levels to quickly set up and manage jobs.

Customizable Parameters: Fine-tune speed, pressure, and tool paths to match specific project requirements, from delicate edge work to heavy-duty milling.

Safety Features: Equipped with safety guards, emergency stop functions, and dust extraction systems to maintain a clean and safe working environment.

Energy Efficient: Designed to minimize power consumption while maximizing output, contributing to a lower operational cost and environmental impact.